Preparation method of instant dried pumpkin

A technology of dried pumpkin and sliced pumpkin, which is applied in food drying, food science, food freezing, etc. It can solve the problems of not being able to meet the needs of consumers, and achieve the effect of retaining nutrition and flavor, golden color, increasing umami taste and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

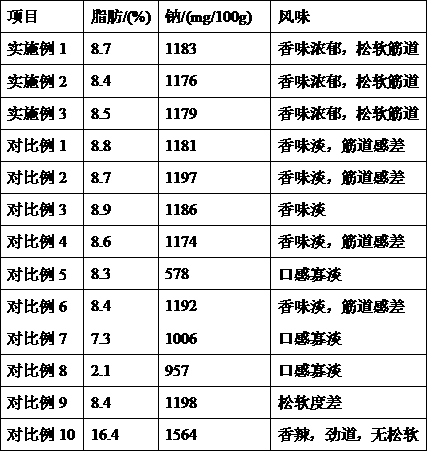

Examples

Embodiment 1

[0023] A preparation method of instant dried pumpkin, comprising the following steps:

[0024] (1) Raw material preparation: wash the old pumpkin, peel and pulp, slice into slices with a thickness of 3-4mm, soak in salt water for 30-40 minutes to obtain pumpkin slices;

[0025] (2) One-time drying: Put the pumpkin slices in an oven and dry at 54°C until the water content is reduced by 20-25%. Spray the soybean oligosaccharide solution on the surface of the pumpkin slices with a mass concentration of 14%. 8% of the weight of the slices, and then dried at 47°C until the water content continued to decrease by 15-20%, so as to increase the strength of the pumpkin slices and avoid soft rot during post-processing, so the pumpkin slices should be dried once;

[0026] (3) Primary fermentation: add lactic acid bacteria to primary dried pumpkin slices, and ferment at 35°C for 3 days to produce rich small molecule nutrients, increase the umami taste and strength of pumpkin slices, promot...

Embodiment 2

[0032] A preparation method of instant dried pumpkin, comprising the following steps:

[0033] (1) Raw material preparation: wash the old pumpkin, peel and pulp, slice into slices with a thickness of 3-4mm, soak in salt water for 30-40 minutes to obtain pumpkin slices;

[0034] (2) One-time drying: Put the pumpkin slices in an oven and dry at 55°C until the water content is reduced by 20-25%. Spray the soybean oligosaccharide solution on the surface of the pumpkin slices with a mass concentration of 15%. 9% of the weight of the slices, and then dried at 48°C until the water content continued to decrease by 15-20%, increasing the strength of the pumpkin slices, avoiding soft rot during post-processing, and drying the pumpkin slices once;

[0035] (3) Primary fermentation: add lactic acid bacteria to primary dried pumpkin slices and ferment at 36°C for 3 days to produce rich small molecule nutrients, increase the umami taste and strength of pumpkin slices, promote gastrointestin...

Embodiment 3

[0041] A preparation method of instant dried pumpkin, comprising the following steps:

[0042] (1) Raw material preparation: wash the old pumpkin, peel and pulp, slice into slices with a thickness of 3-4mm, soak in salt water for 30-40 minutes to obtain pumpkin slices;

[0043] (2) One-time drying: Put the pumpkin slices in an oven and dry at 56°C until the water content is reduced by 20-25%. Spray the soybean oligosaccharide solution on the surface of the pumpkin slices with a mass concentration of 16%. 10% of the weight of the slices, and then dried at 49°C until the water content continued to decrease by 15-20%, increasing the strength of the pumpkin slices, avoiding soft rot during post-processing, and drying the pumpkin slices once;

[0044] (3) Primary fermentation: Add lactic acid bacteria to primary dried pumpkin slices and ferment at 37°C for 4 days to produce rich small molecule nutrients, increase the umami taste and strength of pumpkin slices, and promote gastroint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com