Modified asphalt waterproof coiled material with root penetration resistance and production method of coiled material

A technology for modifying asphalt and waterproofing membranes, used in asphalt coatings, antifouling/underwater coatings, chemical instruments and methods, etc. It is not high, the production process is cumbersome, etc., to achieve the effect of good resistance to mold reproduction, enhanced chemical affinity, and increased lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

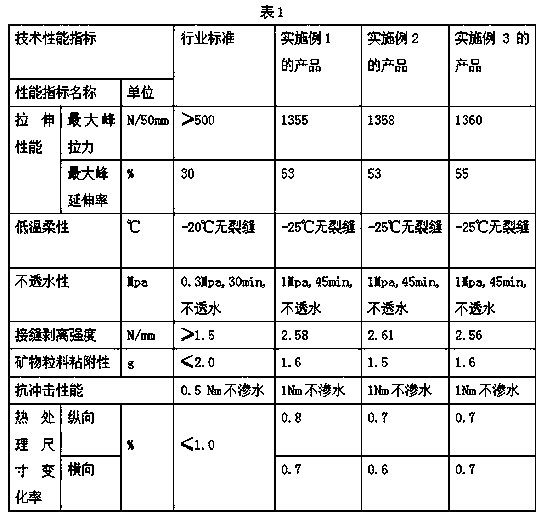

Embodiment 1

[0027] A modified asphalt root puncture-resistant waterproof membrane, the waterproof membrane is a five-layer structure, from top to bottom: the upper surface isolation layer, the upper modified asphalt layer, the base layer, the lower modified asphalt layer and the lower Surface isolation layer; the upper surface isolation layer is PE isolation film, the lower surface isolation layer is polyethylene film; the base layer is composite copper base;

[0028] The upper modified asphalt layer and the lower modified asphalt layer are made of modified asphalt, and the modified asphalt is made of the following raw materials in parts by weight: 65 parts of 90# petroleum asphalt; 10 parts of 70# petroleum asphalt; 25 parts; 18 parts of styrene-butadiene rubber; 13 parts of phenolized lignin; 1 part of polyvinyl alcohol; 1 part of N-phenyl-3-aminopropyltrimethoxysilane; 2 parts of chemical root inhibitor; tributyl citrate 1 part of ester, 0.3 part of hydrogenated rosin pentaerythritol e...

Embodiment 2

[0038] A modified asphalt root puncture-resistant waterproof membrane, the waterproof membrane is a five-layer structure, from top to bottom: the upper surface isolation layer, the upper modified asphalt layer, the base layer, the lower modified asphalt layer and the lower Surface isolation layer; the upper surface isolation layer is PET isolation film, the lower surface isolation layer is polyethylene film; the base layer is composite copper base;

[0039] The upper modified asphalt layer and the lower modified asphalt layer are made of modified asphalt, and the modified asphalt is made of the following raw materials in parts by weight: 70 parts of 90# petroleum asphalt; 12 parts of 70# petroleum asphalt; 28 parts; 19 parts of styrene-butadiene rubber; 15 parts of phenolized lignin; 1.5 parts of polyvinyl alcohol; 2 parts of N-phenyl-3-aminopropyltrimethoxysilane; 3 parts of chemical root inhibitor; tributyl citrate 2 parts of ester, 0.4 part of hydrogenated rosin pentaerythr...

Embodiment 3

[0049] A modified asphalt root puncture-resistant waterproof membrane, the waterproof membrane is a five-layer structure, from top to bottom: the upper surface isolation layer, the upper modified asphalt layer, the base layer, the lower modified asphalt layer and the lower Surface isolation layer; the upper surface isolation layer is PE isolation film, the lower surface isolation layer is polyethylene film; the base layer is composite copper base;

[0050] The upper modified asphalt layer and the lower modified asphalt layer are made of modified asphalt, and the modified asphalt is made of the following raw materials in parts by weight: 75 parts of 90# petroleum asphalt; 15 parts of 70# petroleum asphalt; 30 parts; 20 parts of styrene-butadiene rubber; 17 parts of phenolized lignin; 2 parts of polyvinyl alcohol; 3 parts of N-phenyl-3-aminopropyltrimethoxysilane; 4 parts of chemical root inhibitor; tributyl citrate 3 parts of esters, 0.5 parts of hydrogenated rosin pentaerythri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com