A kind of potassium niobate modified bt-kbt based energy storage ceramics and preparation method thereof

A technology for potassium niobate and energy storage, applied in the field of BT-KBT-based energy storage ceramics modified by potassium niobate and its preparation, can solve the problems of low energy storage density and achieve simple operation, low cost and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

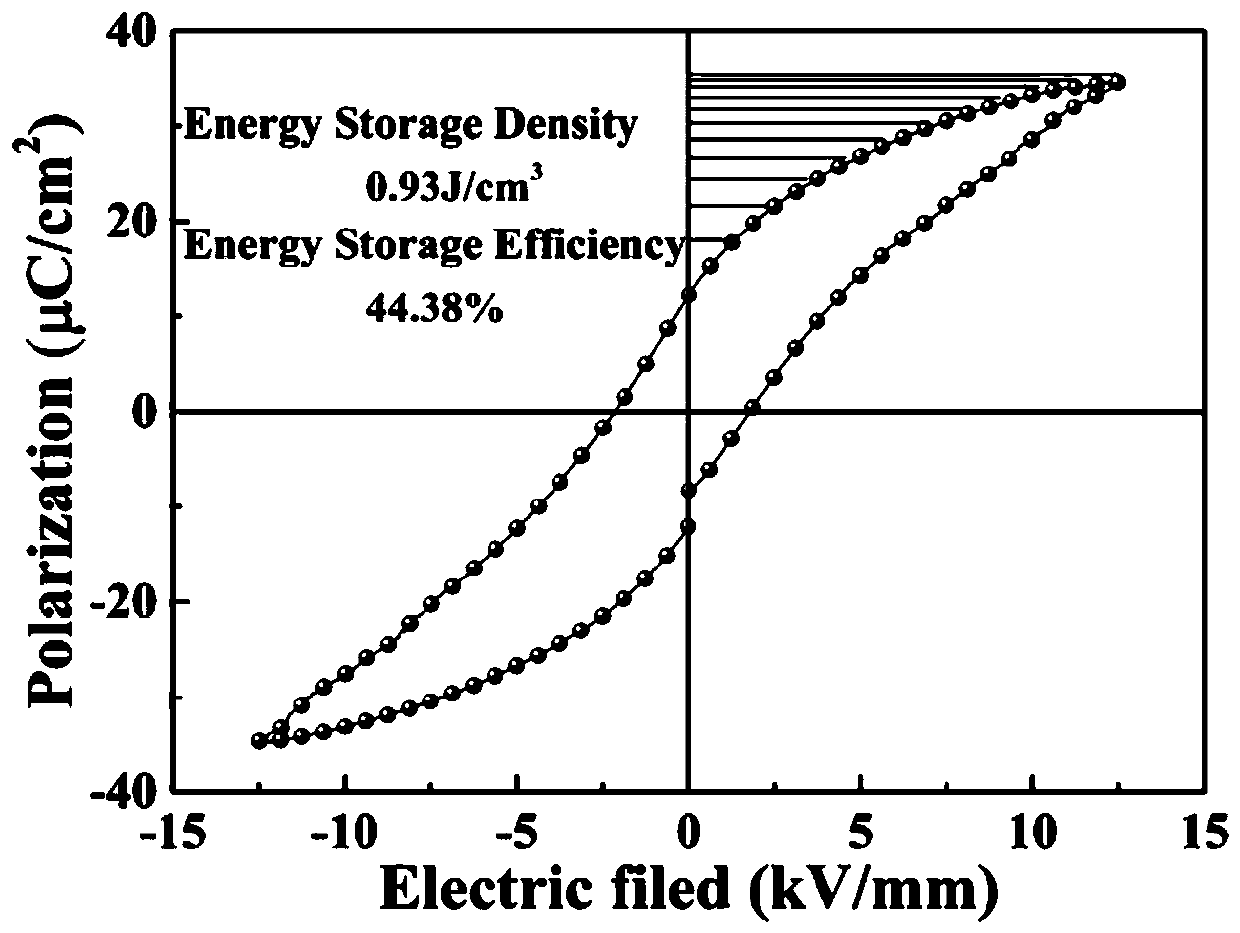

Embodiment 1

[0028] A preparation method of potassium niobate modified BT-KBT based energy storage ceramic material, comprising the following steps:

[0029] 1) According to the chemical formula BaTiO 3 (BT), mix barium carbonate and titanium dioxide uniformly and keep warm at 1150°C for 3 hours to prepare BT ceramic powder. ;

[0030] 2) According to chemical formula K 0.5 Bi 0.5 TiO 3 (KBT), potassium carbonate, bismuth oxide and titanium dioxide were mixed uniformly and kept at 950°C for 4 hours to obtain KBT ceramic powder.

[0031] 3) According to the chemical formula KNbO 3 (KN), mix potassium carbonate and niobium pentoxide evenly and keep it warm at 800°C for 2 hours to prepare potassium niobate ceramic powder.

[0032] 4) BT ceramic powder, KBT ceramic powder and potassium niobate powder according to chemical formula 0.96 (0.92BaTiO 3 -0.08(K 1 / 2 Bi 1 / 2 )TiO 3 )-0.04KNbO 3 The ingredients are mixed evenly by ball milling for 6 hours with deionized water as the ball mill...

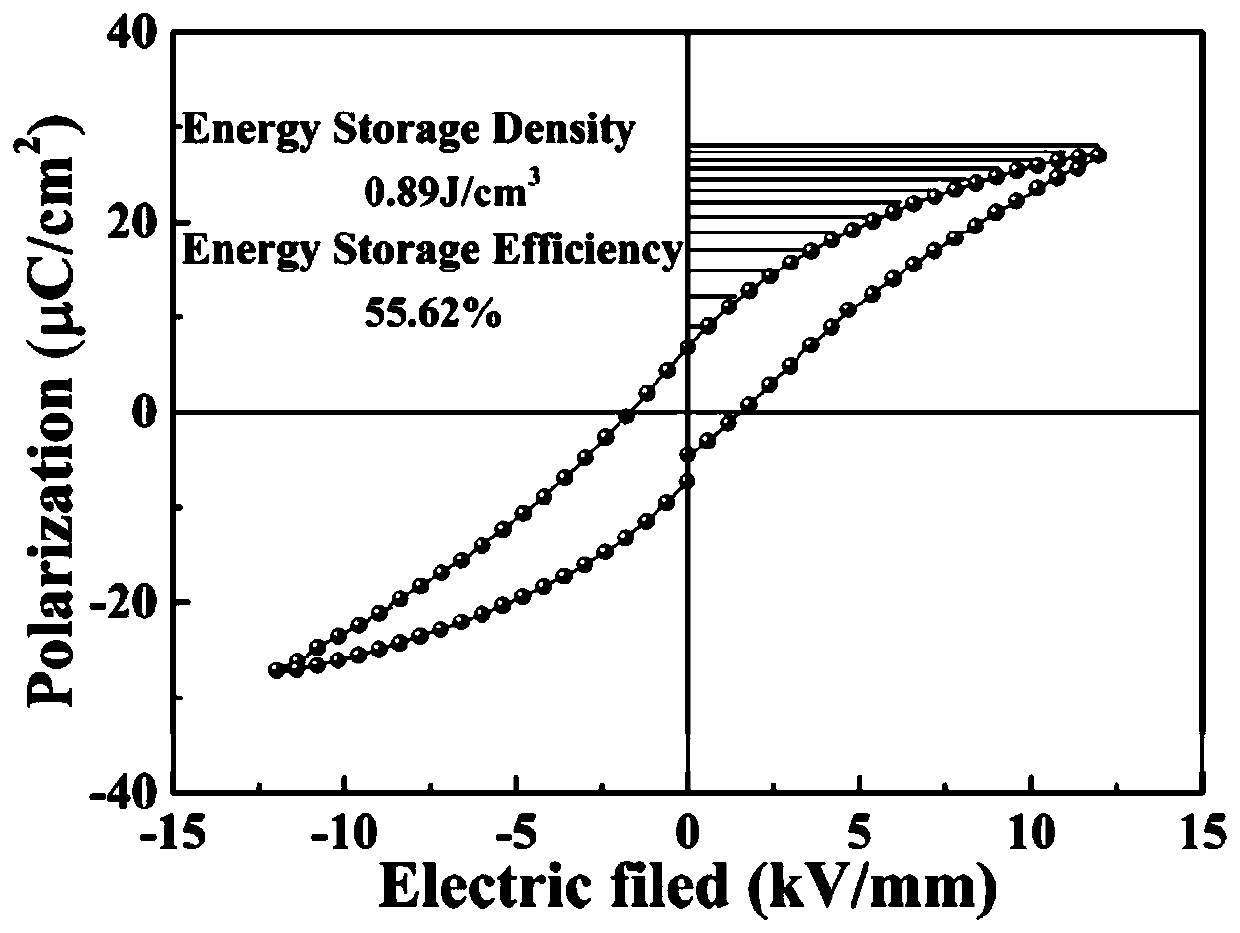

Embodiment 2

[0034] A preparation method of potassium niobate modified BT-KBT based energy storage ceramic material, comprising the following steps:

[0035] 1) According to the chemical formula BaTiO 3 (BT), mix barium carbonate and titanium dioxide uniformly and keep warm at 1150°C for 3 hours to prepare BT ceramic powder. ;

[0036] 2) According to chemical formula K 0.5 Bi 0.5 TiO 3 (KBT), potassium carbonate, bismuth oxide and titanium dioxide were mixed uniformly and kept at 950°C for 4 hours to obtain KBT ceramic powder.

[0037] 3) According to the chemical formula KNbO 3 (KN), mix potassium carbonate and niobium pentoxide evenly and keep it warm at 800°C for 2 hours to prepare potassium niobate ceramic powder.

[0038] 4) BT ceramic powder, KBT ceramic powder and potassium niobate powder according to chemical formula 0.96 (0.92BaTiO 3 -0.08(K 1 / 2 Bi 1 / 2 )TiO 3 )-0.04KNbO 3 The ingredients were mixed evenly by ball milling for 6 hours with deionized water as the ball mil...

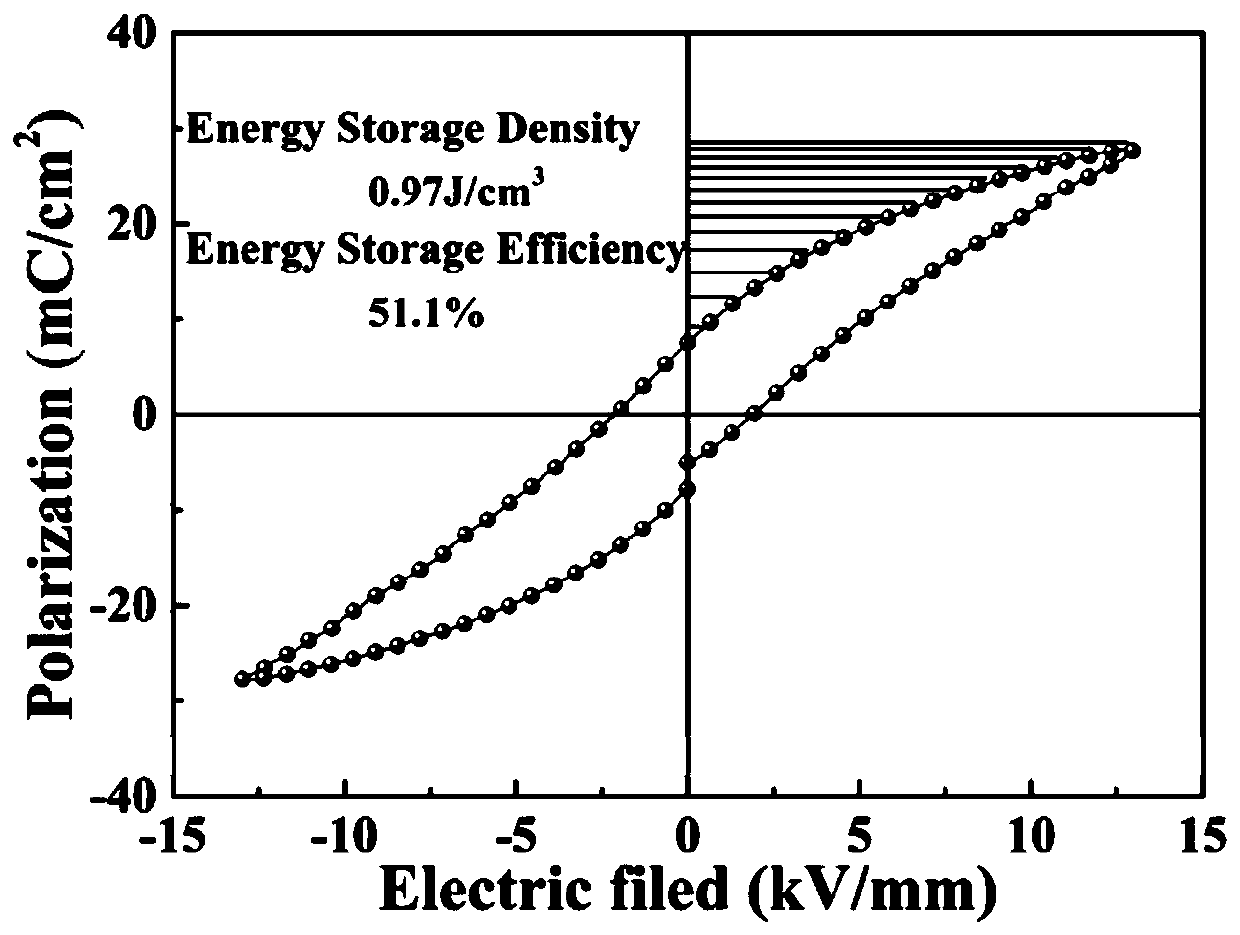

Embodiment 3

[0040] A preparation method of potassium niobate modified BT-KBT based energy storage ceramic material, comprising the following steps:

[0041] 1) According to the chemical formula BaTiO 3 (BT), mix barium carbonate and titanium dioxide uniformly and keep warm at 1150°C for 3 hours to prepare BT ceramic powder. ;

[0042]2) According to chemical formula K 0.5 Bi 0.5 TiO 3 (KBT), potassium carbonate, bismuth oxide and titanium dioxide were mixed uniformly and kept at 950°C for 4 hours to obtain KBT ceramic powder.

[0043] 3) According to the chemical formula KNbO 3 (KN), mix potassium carbonate and niobium pentoxide evenly and keep it warm at 800°C for 2 hours to prepare potassium niobate ceramic powder.

[0044] 4) BT ceramic powder, KBT ceramic powder and potassium niobate powder according to chemical formula 0.96 (0.92BaTiO 3 -0.08(K 1 / 2 Bi 1 / 2 )TiO 3 )-0.04KNbO 3 The ingredients were mixed evenly by ball milling for 6 hours with deionized water as the ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com