Self-cleaning type anti-fouling liquid and preparation method thereof

An antifouling liquid, self-cleaning technology, applied in the field of materials, can solve the problems of accumulation of oil and grease, rust and corrosion damage to appliances, troublesome cleaning, etc., and achieve the effect of simple production process, good construction effect, and excellent aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

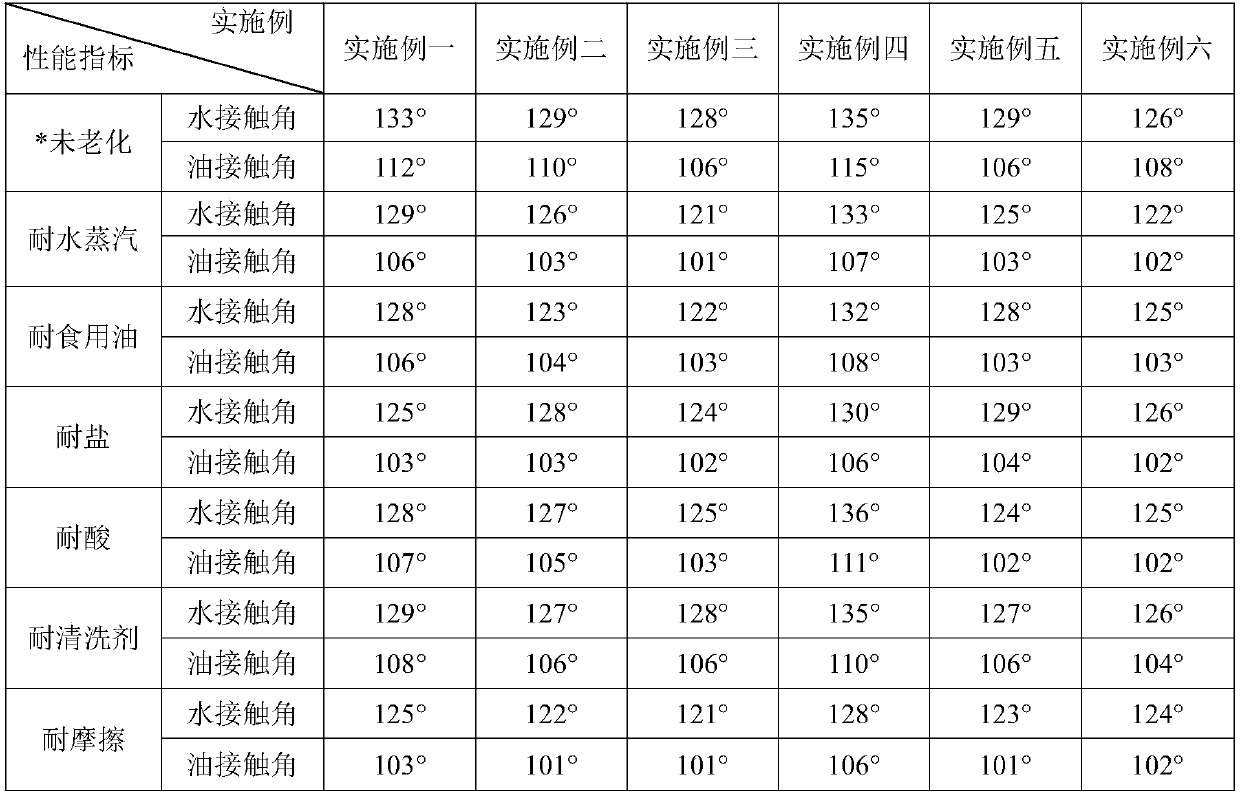

Examples

Embodiment 1

[0023] The preparation method of the present embodiment self-cleaning type antifouling liquid, its steps are as follows:

[0024] (1) Add 2L of absolute ethanol to a three-necked flask equipped with a back distillation device, stir and heat to 40°C, add NaOH solution with a concentration of 20%, and adjust the pH value to 10.4-10.6;

[0025] (2) Add 300mL tetraethyl orthosilicate, keep the above temperature and continue stirring for 60min;

[0026] (3) Add 50mL (C 3 f 7 )-CH 2 -Si(OC 2 h 5 ) 3 , keep the above temperature and continue to stir and mix the reaction for 120min;

[0027] (4) Add 15% HCl solution dropwise at a constant speed within 20 minutes, adjust the pH value of the mixed solution system to 6.8-7.0, keep the above temperature and continue stirring for 30 minutes, and then prepare the self-cleaning antifouling solution after cooling.

Embodiment 2

[0029] The preparation method of the present embodiment self-cleaning type antifouling liquid, its steps are as follows:

[0030] (1) Add 2L of absolute ethanol to a three-necked flask equipped with a back distillation device, stir and heat to 45°C, add tetrabutylammonium hydroxide solution with a concentration of 25%, and adjust the pH value to 10.0-10.2;

[0031] (2) Add 500mL tetraethyl orthosilicate, keep the above temperature and continue stirring for 80min;

[0032] (3) Add 60mL (C 7 f 15 )-C 2 h 5 -Si(OCH 3 ) 3 , keep the above temperature and continue to stir and mix the reaction for 150min;

[0033] (4) Add 15% HCl solution dropwise at a constant speed within 20 minutes, adjust the pH value of the mixed solution system to 6.8-7.0, keep the above temperature and continue stirring for 20 minutes, and then prepare the self-cleaning antifouling solution after cooling.

Embodiment 3

[0035] The preparation method of the present embodiment self-cleaning type antifouling liquid, its steps are as follows:

[0036] (1) Add 2L of absolute ethanol to a three-necked flask equipped with a back distillation device, stir and heat to 40°C, add KOH solution with a concentration of 10%, and adjust the pH value to 11.8-12.0;

[0037] (2) Add 500mL orthopropyl silicate, keep the above temperature and continue stirring for 40min;

[0038] (3) Add 60mL (C 9 f 19 )-CH 2 -Si(OCH 3 ) 3 , keep the above temperature and continue to stir and mix the reaction for 90min;

[0039] (4) Add CH at a uniform rate of 30% within 20 minutes 3 COOH liquid, adjust the pH value of the mixed liquid system to 7.0-7.2, keep the above temperature and continue to stir and react for 40 minutes, after cooling, the self-cleaning antifouling liquid is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com