Modified and unmodified mesoporous metal-organic framework compounds as well as preparation methods and application thereof

A metal-organic framework and organic framework technology, applied in the field of material chemistry, can solve the problems of weak adsorption capacity and unfavorable catalyst, and achieve the effects of convenient operation, excellent photocatalytic reduction ability and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

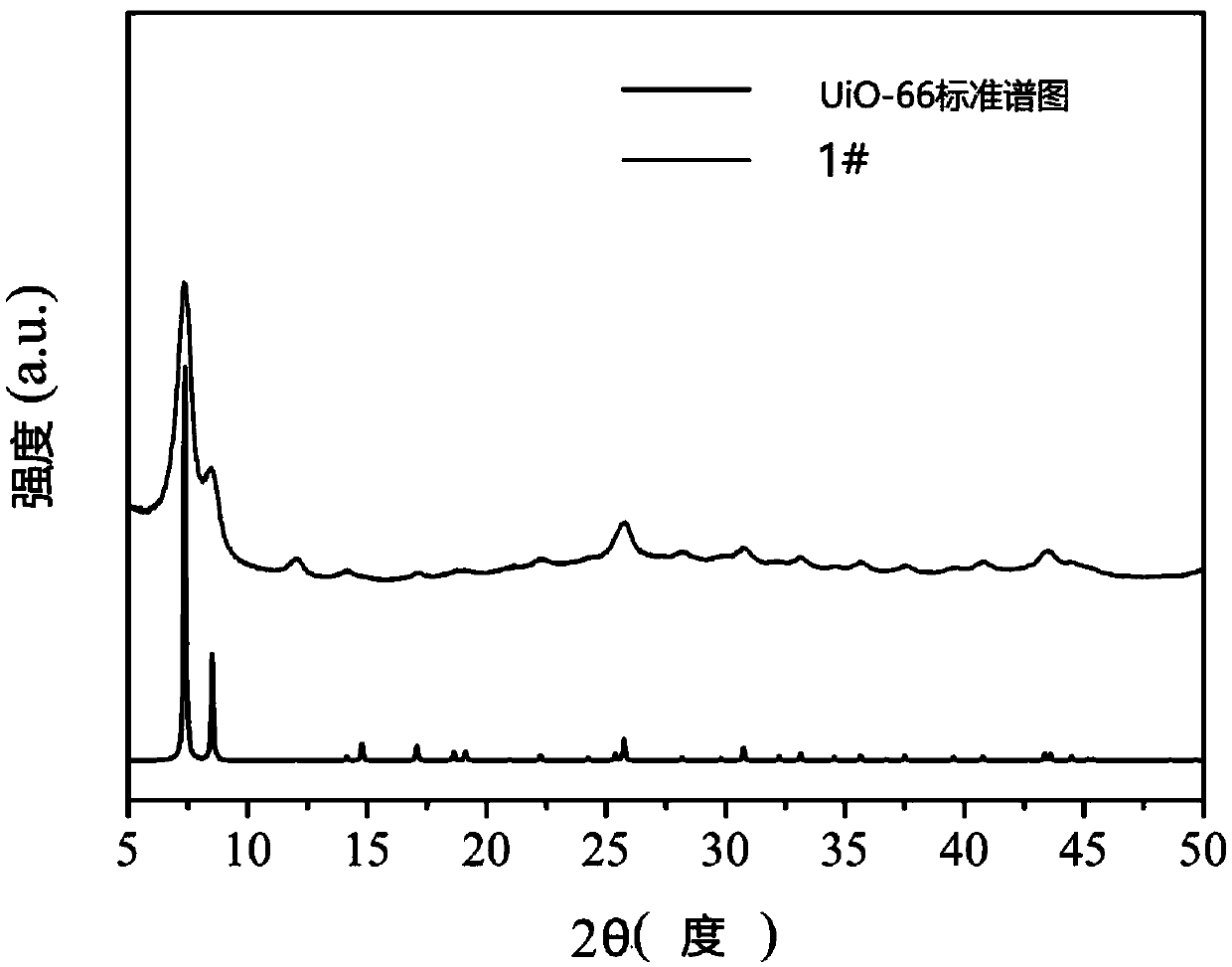

[0057] Example 1 Bifunctional MOFs material sample 1 # Synthesis

[0058] Weigh 3.3g of 1,2,4,5-pyromellitic acid into a reaction bottle containing 50 ml of deionized water, stir for 5 minutes until the ligands are completely dissolved, and then weigh 1g of 2-amino p- Phthalic acid, put into the above solution, continue to stir. After the ligand is dissolved, weigh 2.3 g of zirconium tetrachloride and put it into the above solution, and continue to stir. Then the above solution was refluxed at 100° C. for 24 hours. After cooling to room temperature, the product obtained above was washed three times with deionized water. Finally, put the product obtained above into 50 ml of deionized water, and continue to reflux for 16 hours under the condition of 100° C. to remove unreacted ligands. Finally, the obtained solid product was dried in a vacuum oven at 70°C for 8 hours to obtain the mesoporous metal-organic framework compound, designated as sample 1 # .

Embodiment 2

[0061] Example 2 Bifunctional MOFs material sample 1 # Synthesis

[0062] Adjust the ratio of raw materials and reaction conditions. The specific preparation steps and other conditions are the same as in Example 1. The relationship between the sample number of the obtained sample and the ratio of raw materials and reaction conditions is shown in Table 1.

[0063] Table 1

[0064]

[0065]

Embodiment 3

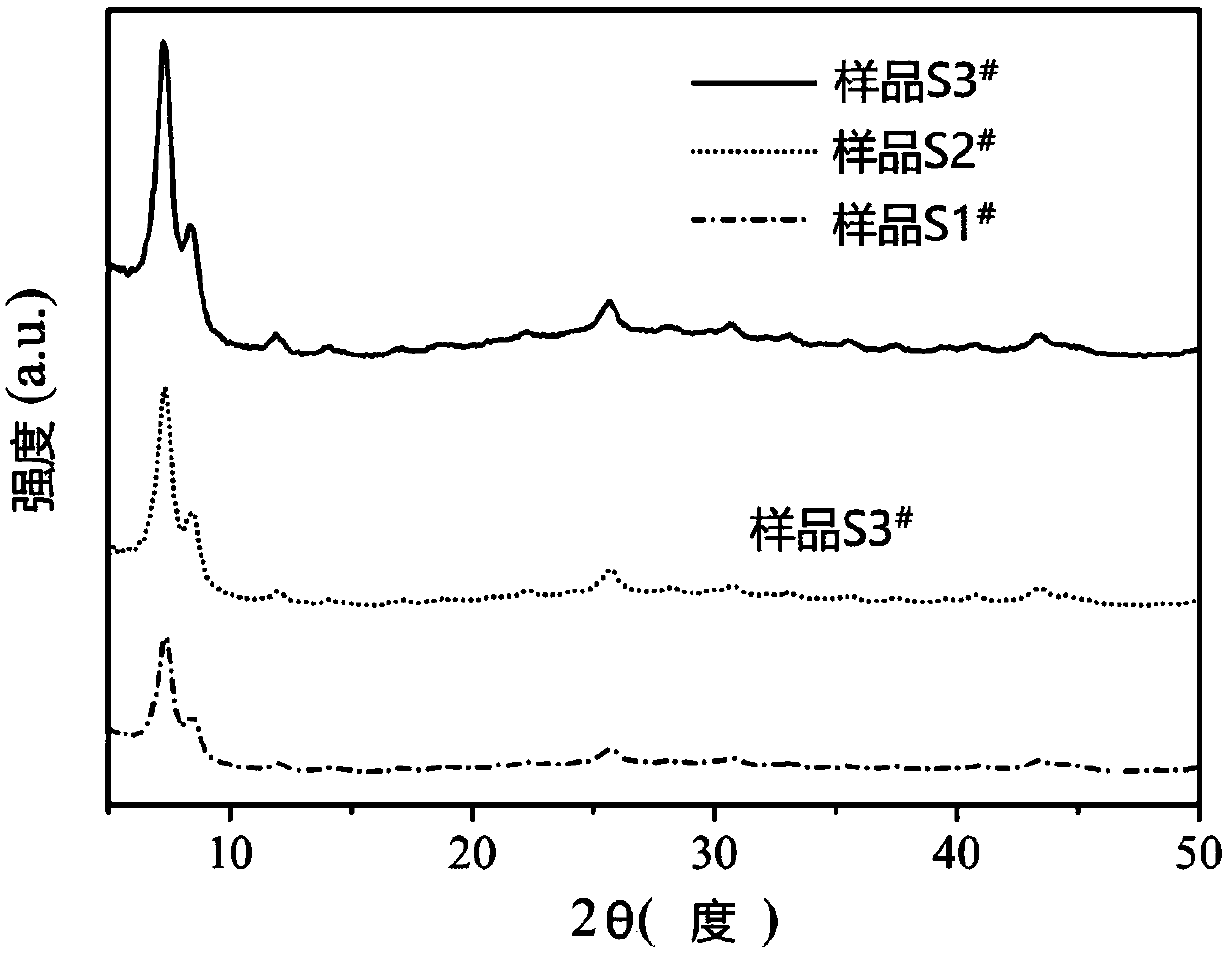

[0066] Example 3 Synthesis of Modified Mesoporous MOFs Materials

[0067] Put 15g of glucose in 25ml of deionized water, ultrasonically dissolve it, then transfer it to a 50ml microwave reaction bottle, and then dry sample 1 in Example 1 # 200 mg was put into the glucose solution, then sealed, put into a microwave reactor, and reacted for 10 minutes at 130°C. After the obtained solid was cleaned by centrifugation, it was dried in a vacuum oven for 8 hours to obtain a glucose-modified MOFs material, designated as sample S1 # .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com