Non-corrosive ketoxime-type room-temperature-cured silicone rubber and preparation method

A room temperature curing, non-corrosive technology, applied in the field of ketoxime room temperature curing silicone rubber and its preparation, to achieve the effects of easy operation, good comprehensive performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

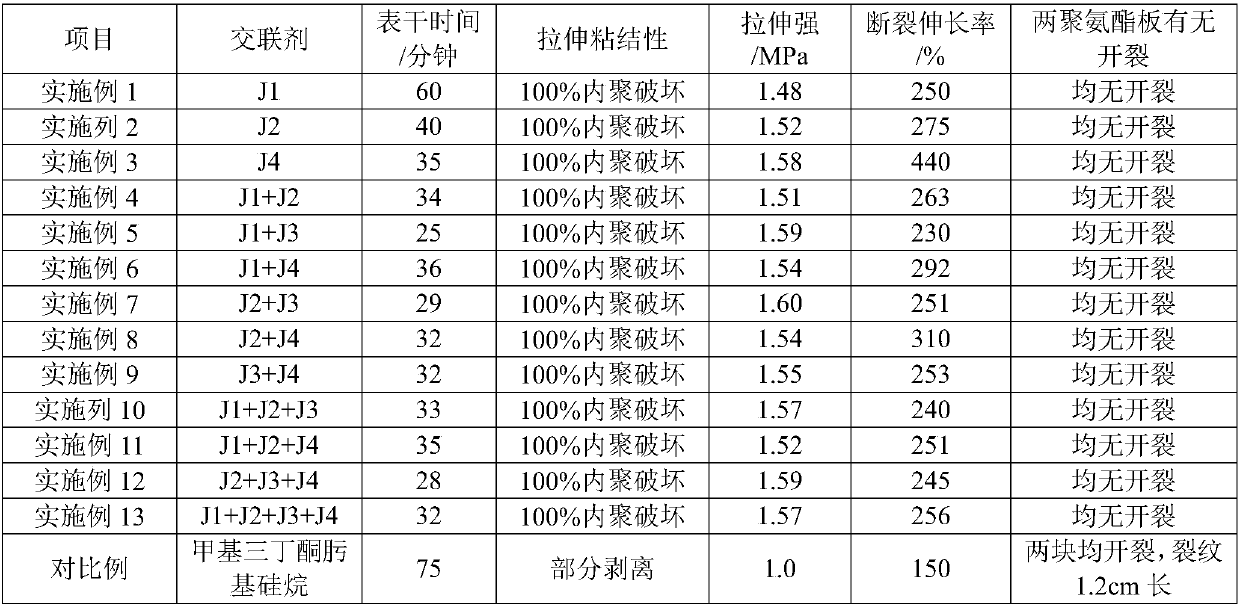

Examples

preparation example Construction

[0024] The preparation method of above-mentioned ketoxime type room temperature curing silicone rubber comprises the following steps:

[0025] (1) Weigh the hydroxyl-terminated polysiloxane, plasticizer, filler and pigment respectively, add them into a planetary mixer or a kneader, and stir in a vacuum for 30-60 minutes;

[0026] (2) Weigh methyl isobutyl ketoxime base silane and add, continue vacuum stirring for 30-60 minutes;

[0027] (3) Weighing the silane coupling agent and adding the catalyst, stirring in vacuum for 30-60 minutes, and packing under nitrogen protection to obtain a room temperature curing silicone rubber compound.

Embodiment 1

[0029] Non-corrosive ketoxime type room temperature curing silicone rubber, its formula consists of 40g of hydroxyl-terminated polysiloxane, 3g of methyl isobutyl ketoxime silane, 1g of silane coupling agent, 5g of plasticizer, 0.1g of catalyst, filler 10g and 1g of pigment are mixed to obtain, wherein methyl isobutyl ketoxime base silane is methyl tris(methyl isobutyl ketoxime base) silane, silane coupling agent is aminosilane coupling agent, plasticizer is silicone oil, and catalyst is Organic tin catalyst, the filler is a mixture of calcium carbonate and white carbon black. Its preparation method is as follows:

[0030] (1) Add the hydroxyl-terminated polysiloxane, plasticizer, filler and pigment into a planetary mixer or kneader, and stir in vacuum for 30 minutes;

[0031] (2) Take methyl tri(methyl isobutyl ketoxime base) silane and add, continue vacuum stirring for 30 minutes;

[0032] (3) Weigh the silane coupling agent and add the catalyst, stir in vacuum for 30 minu...

Embodiment 2

[0034] The non-corrosive ketoxime type room temperature curing silicone rubber is different from Example 1 in that the selected methyl isobutyl ketoxime silane is vinyl tris(methyl isobutyl ketoxime) silane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com