Method for fixed-point functionalization of polyolefin material and continuous production method of fixed-point functionalized polyolefin material

A polyolefin and functionalization technology, applied in the field of fixed-point functionalized polyolefin materials, can solve the problems of limiting the use effect of functionalized PP, the uncontrollable maleic anhydride group, and the inability to actually meet the application requirements. Effects of large-scale industrial production, ease of large-scale industrial production, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

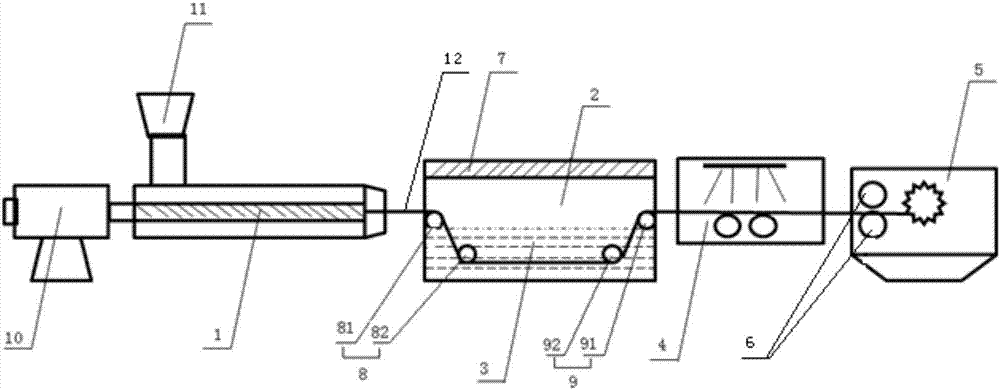

[0092] 1) Stir polypropylene (brand T30S) and di-tert-butyl peroxide evenly (the mass ratio of polypropylene to di-tert-butyl peroxide is 100:0.1) and then add it to a twin-screw extruder (length-to-diameter ratio is 48), The degraded polypropylene wire rod (or simply referred to as "wire") is obtained by melting and extruding in a staged heating manner. The temperature of the feeding section of the twin-screw extruder is 185°C, the temperature of the melting and homogenizing section is 220°C, and the temperature of the head is 210°C. The screw speed was 80 rpm.

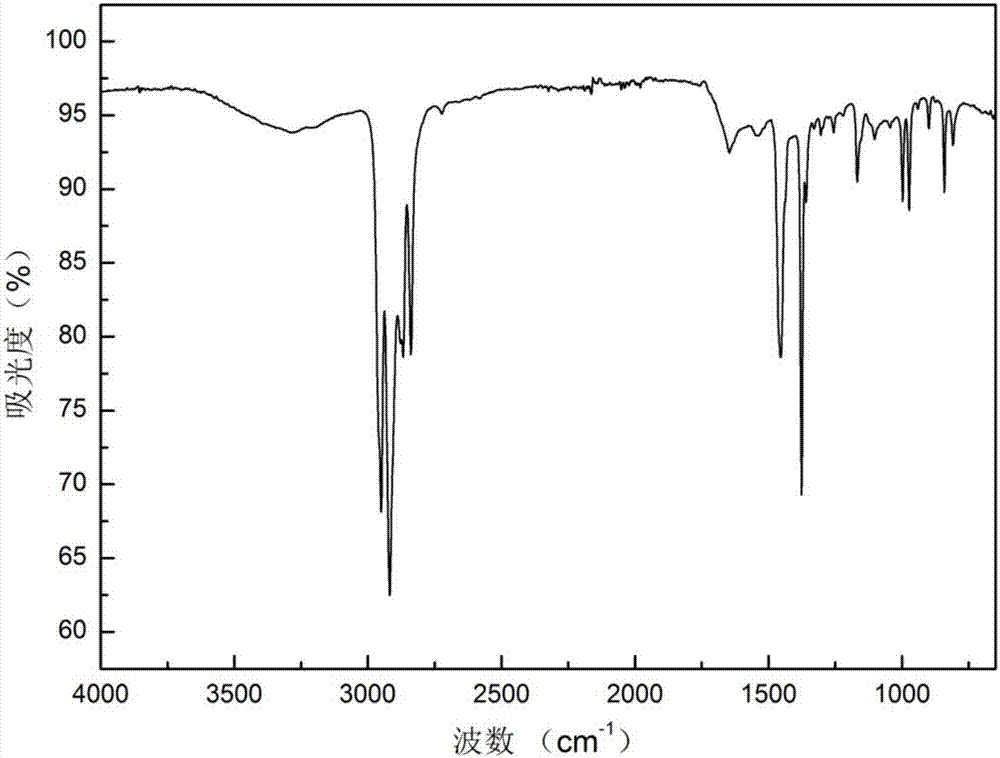

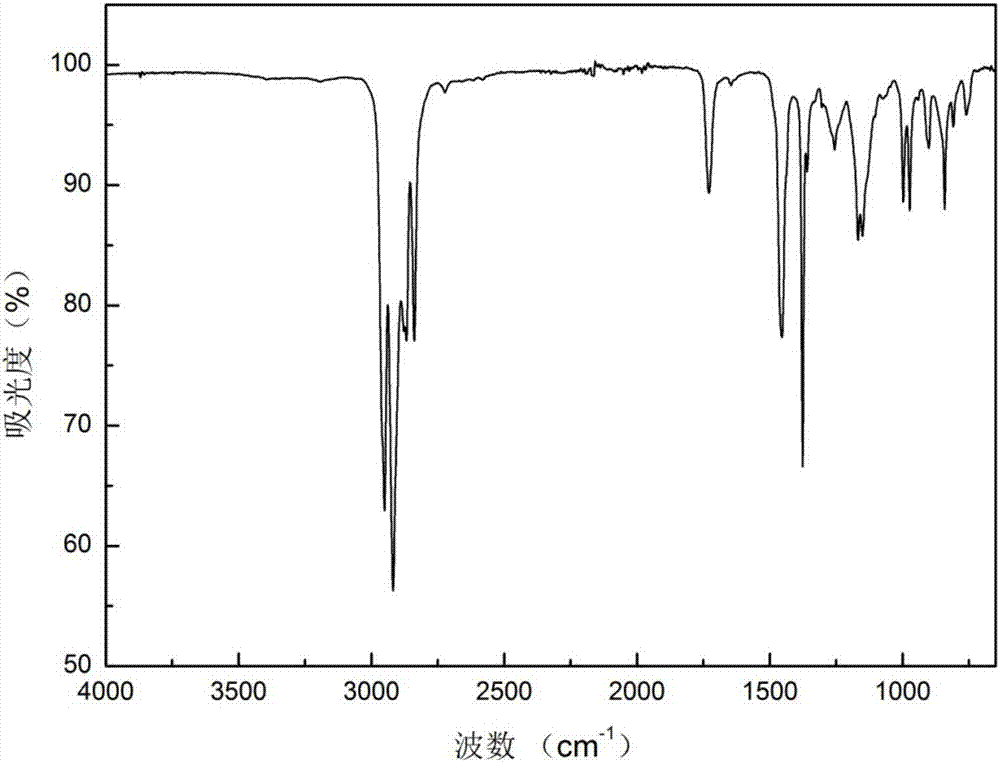

[0093] 2) The degraded polypropylene wire is pulled into the reaction tank by the pulling action of the sliding roller in the pelletizer, the wire is immersed in the reaction solution, the temperature of the reaction solution is 80°C, and the ultraviolet wavelength of the reaction solution is 254nm. 200μW / cm 2 , the residence time of the wire rod in the reaction solution is 300s, and the end group functionalization ...

Embodiment 2

[0102] 1) Stir polypropylene (grade PP-H-GD320) and 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane evenly (polypropylene and 2,5-dimethyl -2,5-bis(tert-butyl peroxy) with a mass ratio of 100:0.1) was added to a twin-screw extruder (aspect ratio of 48), and melted and extruded by segmental heating to obtain degraded polypropylene wire (or simply referred to as "wire"), the temperature of the feeding section of the twin-screw extruder is 130°C, the temperature of the melting and homogenizing section is 230°C, the temperature of the head is 190°C, and the screw speed is 300 rpm.

[0103] 2) The degraded polypropylene wire is drawn into the reaction solution tank by the pulling effect of the sliding roller in the pelletizer, the wire is immersed in the reaction solution, the temperature of the reaction solution is 100°C, and the ultraviolet wavelength of the reaction solution is irradiated at 254nm. Intensity is 100μW / cm 2 , the residence time of the wire rod in the reaction soluti...

Embodiment 3

[0112] 1) Stir propylene and α-olefin copolymer (brand name Vistamaxx6102) and dicumyl peroxide evenly (the mass ratio of polyolefin to dicumyl peroxide is 100:10) and then add them into a twin-screw extruder (long diameter The ratio is 48), and the degraded polypropylene wire (or simply referred to as "wire") is obtained by melting and extruding in a staged heating manner. The temperature of the feeding section of the twin-screw extruder is 190 ° C, and the temperature of the melting and homogenizing section is 190 ° C. The temperature is 190° C., and the screw speed is 50 rpm.

[0113] 2) The degraded polypropylene wire is drawn into the reaction tank by the pulling effect of the sliding roller in the pelletizer, the wire is immersed in the reaction solution, the temperature of the reaction solution is 65°C, and the ultraviolet wavelength of the reaction solution is 365nm. 50μW / cm 2 , the residence time of the wire rod in the reaction solution is 200s, and the end group fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com