Environment-friendly plastic macromolecular nanometer color masterbatch with anti-haze function and method for preparing environment-friendly plastic macromolecular nanometer color masterbatch

A technology of environmentally friendly plastics and manufacturing methods, applied in the field of plastic materials, can solve the problems of reducing the degradation rate of fully biodegradable plastics, achieve strong dispersion, improve processing performance and application performance, and increase product brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

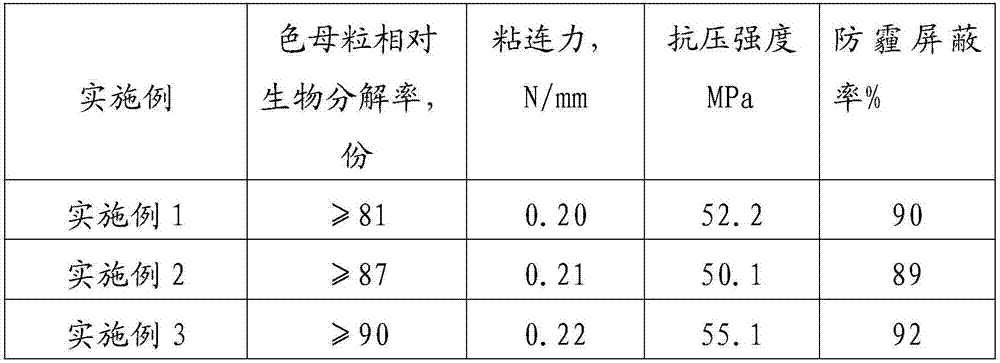

Examples

Embodiment 1

[0021] Embodiment 1 of the present invention provides a kind of environment-friendly plastic macromolecule nano-color masterbatch with anti-smog function, by weight percentage, comprises composition: Calcium zeolite 25 parts, hollow glass microsphere 30 parts, alkyd resin 15 parts, 15 parts of silicic acid fiber, 30 parts of pitch-based carbon fiber powder, 10 parts of polycarboxylic acid, 5 parts of waterproofing agent, 20 parts of polyvinyl alcohol resin, 25 parts of modified SiO, 5 parts of anti-blocking agent magnesium stearate, 20 parts of plastic carrier 5 parts of starch, 5 parts of pigment, 0.1 part of coupling agent, 1 part of plasticizer, 0.2 part of lubricant, 0.5 part of antioxidant, 0.1 part of dispersant;

[0022] The waterproofing agent is a mixture of octyltriethoxysilane and polymethyltriethoxysilane with a mass ratio of 3:1. The coupling agent is KH550, the plasticizer is methyl cellulose, the lubricant is glycerin, and the antioxidant is sorbic acid.

[002...

Embodiment 2

[0034] Embodiment 2 of the present invention provides a kind of environment-friendly plastic macromolecule nano-color masterbatch with anti-haze function, which comprises composition by weight percentage: 30 parts of calcium zeolite, 35 parts of hollow glass microspheres, 17 parts of alkyd resin, 20 parts of silicic acid fiber, 35 parts of pitch-based carbon fiber powder, 7 parts of waterproofing agent, 25 parts of polyvinyl alcohol resin, 10 parts of modified SiO, 8 parts of anti-blocking agent magnesium stearate, 40 parts of plastic carrier, 10 parts of starch, 15 parts of pigment, 0.8 part of coupling agent, 4 parts of plasticizer, 2 parts of lubricant, 1 part of antioxidant, and 2 parts of dispersant.

[0035] Described cellulose is hydroxyethyl cellulose; Film-forming aid is alcohol ester twelve; Described waterproofing agent is the mixture of octyltriethoxysilane and polymethyltriethoxysilane, and mass ratio is 3: 1.

[0036] The plastic carrier is a biodegradable plast...

Embodiment 3

[0047] Embodiment 3 of the present invention provides a kind of environment-friendly plastic macromolecule nano-color masterbatch with anti-haze function, by weight percentage, comprises composition: Calcium zeolite 35 parts, hollow glass microsphere 40 parts, alkyd resin 20 parts, 25 parts of silicic acid fiber, 40 parts of pitch-based carbon fiber powder, 10 parts of waterproofing agent, 30 parts of polyvinyl alcohol resin, 28 parts of modified SiO, 10 parts of anti-blocking agent magnesium stearate, 60 parts of plastic carrier, 15 parts of starch, 25 parts of pigment, 1.5 parts of coupling agent, 7 parts of plasticizer, 3 parts of lubricant, 2.5 parts of antioxidant, 4 parts of dispersant.

[0048] The waterproofing agent is a mixture of octyltriethoxysilane and polymethyltriethoxysilane with a mass ratio of 3:1.

[0049] The plastic carrier is a biodegradable plastic carrier, and the biodegradable plastic carrier is polyhydroxyalkanoate.

[0050] Described modified SiO Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap