Long-acting antistatic silicone rubber/ionic liquid composite material and preparation method thereof

The technology of ionic liquid and composite material is applied in the field of long-acting antistatic silicone rubber/ionic liquid composite material and its preparation, which can solve the problems of lack of long-acting antistatic, antistatic property of silicone rubber or decreased electrical conductivity, etc. Achieve the effect of good mechanical properties, good stability and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

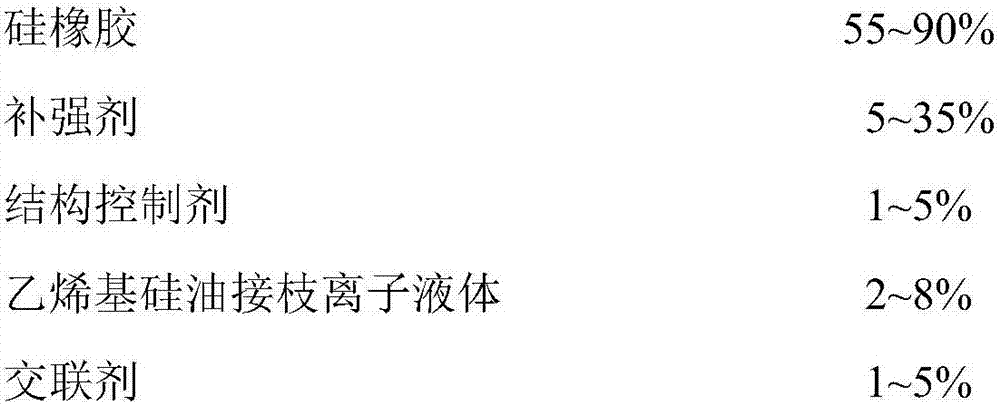

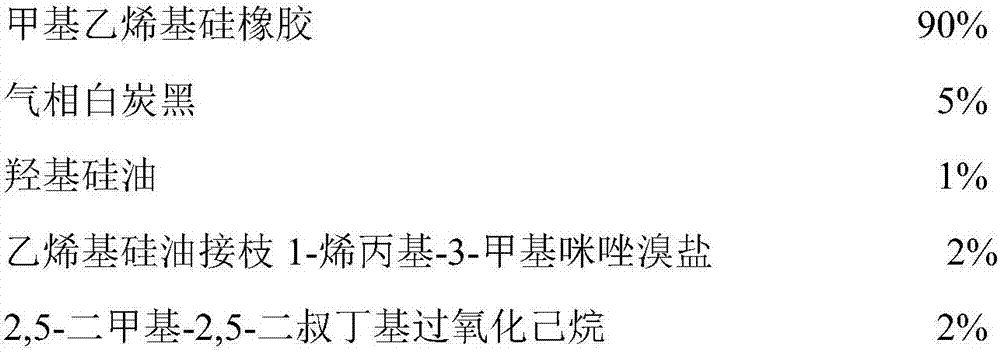

[0030] The proportion of each component of the long-acting antistatic silicone rubber / ionic liquid composite material is:

[0031]

[0032] Dissolve vinyl silicone oil with a viscosity of 200mPa·s and a vinyl content of 0.8mol% in toluene (the mass ratio of vinyl silicone oil to toluene is 1:4), add ionic liquid, and then add AIBN (vinyl silicone oil, ionic liquid The mass ratio of AIBN to AIBN is 100:5:1), stirred at 60°C for 24h, protected by nitrogen, evaporated toluene, and then returned to the reaction vessel after cooling with water to ensure that the amount of toluene remained basically unchanged. Vinyl silicone oil and ionic liquid The reaction product was washed with ethanol for 3 times, and then dried in an oven at 60° C. for 6 h to obtain vinyl silicone oil grafted 1-allyl-3-methylimidazolium bromide.

[0033] First, mix methyl vinyl silicone rubber, fumed silica and hydroxyl silicone oil in a rubber mill, then add vinyl silicone oil to graft 1-allyl-3-methylimid...

Embodiment 2

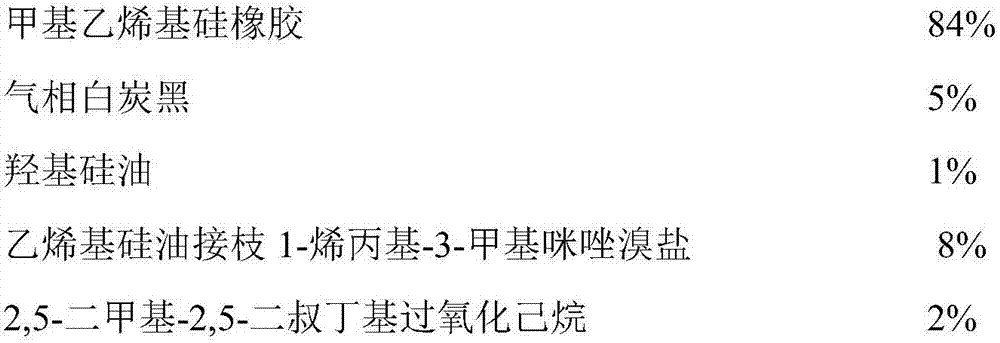

[0035] The proportion of each component of the long-acting antistatic silicone rubber / ionic liquid composite material is:

[0036]

[0037] Dissolve vinyl silicone oil with a viscosity of 200mPa·s and a vinyl content of 0.8mol% in xylene (the mass ratio of vinyl silicone oil to xylene is 1:8), add ionic liquid, and then add AIBN (vinyl silicone oil, The mass ratio of ionic liquid to AIBN is 100:5:1), stirred at 80°C for 12h, protected by nitrogen, evaporated xylene, and then refluxed to the reaction vessel after cooling with water to ensure that the amount of xylene remained basically unchanged. The reaction product of silicone oil and ionic liquid was washed with ethanol for 6 times, and then the product was dried in an oven at 100° C. for 2 h to prepare vinyl silicone oil grafted 1-allyl-3-methylimidazolium bromide.

[0038]First, mix methyl vinyl silicone rubber, fumed silica and hydroxyl silicone oil in a rubber mill, then add vinyl silicone oil to graft 1-allyl-3-methy...

Embodiment 3

[0040] The proportion of each component of the long-acting antistatic silicone rubber / ionic liquid composite material is:

[0041]

[0042] Dissolve vinyl silicone oil with a viscosity of 1000mPa·s and a vinyl content of 1.9mol% in carbon tetrachloride (the mass ratio of vinyl silicone oil to carbon tetrachloride is 1:5), add ionic liquid, and then add AIBN ( The mass ratio of vinyl silicone oil, ionic liquid and AIBN is 100:5:1), stirred at 65°C for 12h, protected by nitrogen, evaporated carbon tetrachloride, and then returned to the reaction vessel after cooling with water to ensure that carbon tetrachloride The dosage remains basically the same, the reaction product of vinyl silicone oil and ionic liquid is washed with ethanol for 3 times, and then the product is dried in an oven at 100°C for 2 hours to obtain vinyl silicone oil grafted 1-allyl-3-methylimidazole Bromide.

[0043] First, mix methyl vinyl silicone rubber, fumed silica and hydroxyl silicone oil in a rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com