Preparation method of nano-microcapsule adopting chitosan-TPP-KGM as compound wall material

A technology of -TPP-KGM and nano-microcapsules, which is applied in the field of preparation of nano-microcapsules, can solve the problems of no high-strength spherical shape, complicated preparation process, loss of core material, etc., to achieve large-scale application and process The effect of mild and simple conditions and high load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

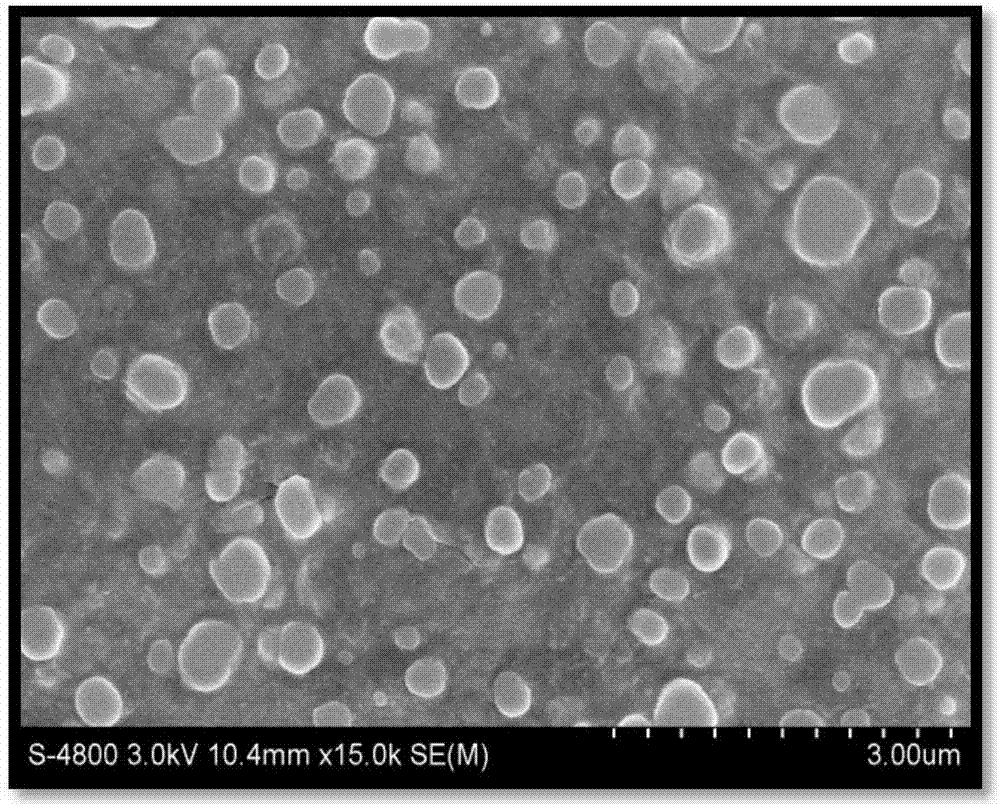

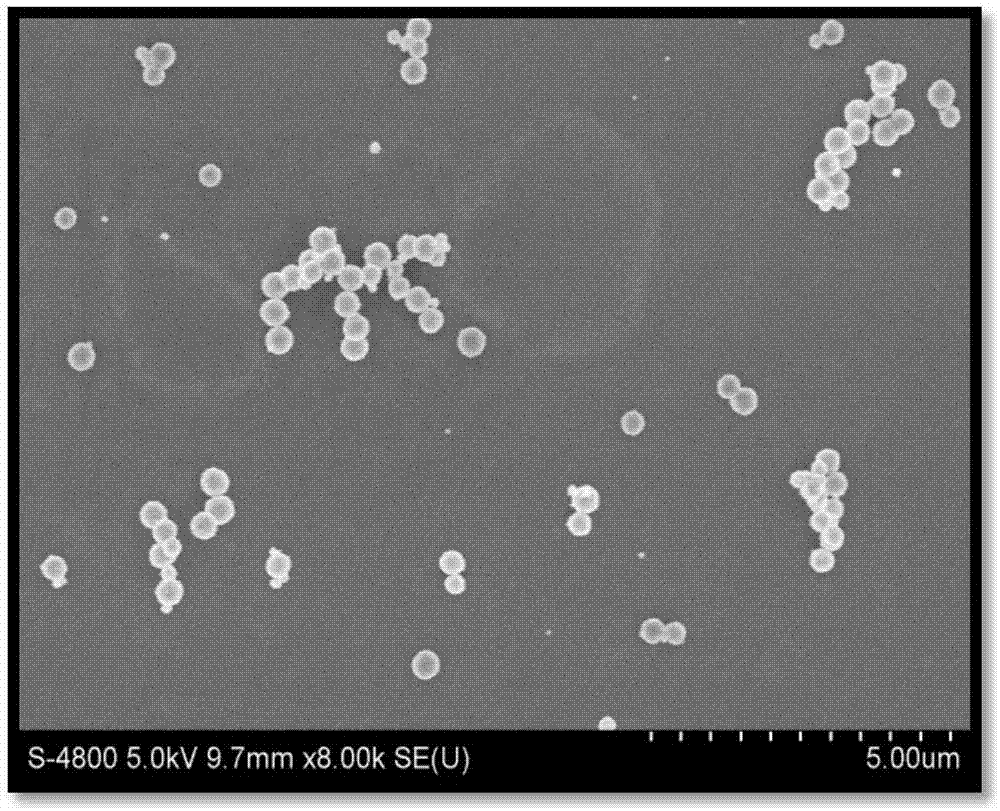

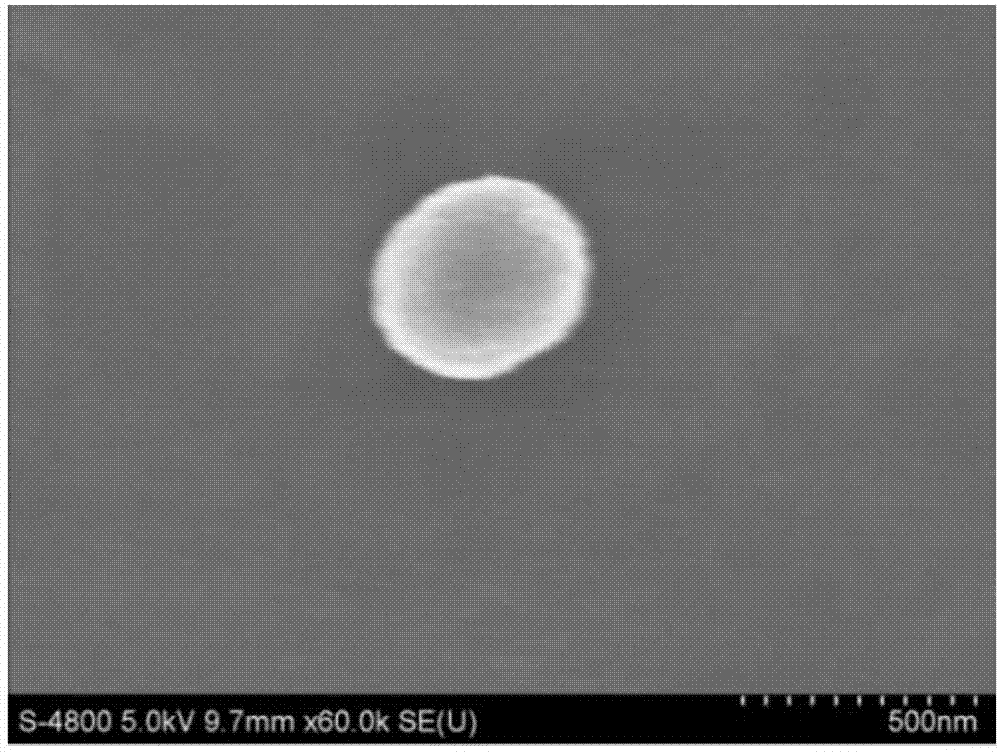

[0030] Preparation of Chitosan-TPP-KGM Nanocapsules

[0031] 1) Prepare a chitosan solution with a mass fraction of 0.2-0.5% (%, w / v), mix the TPP solution with the KGM solution, and add the mixture of the two substances into the chitosan solution dropwise.

[0032] 2) Add dropwise with magnetic stirring, until the dropwise addition of the mixture is complete, continue to stir at 10-50°C for 15-60min, collect the nanocapsules by centrifugation, and rinse with double distilled water three times to obtain chitosan-TPP-KGM composite nanocapsules.

[0033] Wherein, the mass ratio of chitosan / TPP / KGM is 6 / 1 / 1.2-6 / 1 / 3 respectively.

[0034] Chitosan-TPP-KGM nanocapsules coated casein phosphopeptides (CPPs)-Ca 2+ Application of Composite Core Material

[0035] CPP-Ca 2+ The complex was dissolved in Tris-HCl buffer (pH 7.4, 20 mM) to obtain a core material solution. Prepare a chitosan solution with a mass fraction of 0.2-0.5% (%, w / v), mix the TPP solution with the KGM solution, ...

Embodiment 1

[0039] Take chitosan in weighing paper and dissolve it in 1% acetic acid solution at room temperature, and obtain a chitosan solution with a mass fraction of 0.2% under magnetic stirring; weigh TPP powder and dissolve it in water to obtain a concentration of 3.3mg / ml of TPP solution; weigh KGM in a beaker, slowly add double distilled water with vigorous stirring to obtain a KGM solution with a concentration of 1 mg / ml. Weigh 0.5g CPP-Ca 2+ The complex is dissolved in a Tris-HCl buffer solution with a pH of 7.4 and 20 mmol / L to obtain a core material solution with a concentration of 50 mg / ml. Mix 0.6ml of TPP solution with 2.4ml of KGM solution, then add 1ml of core material solution, add the mixture of these three substances into 6ml of chitosan solution drop by drop at room temperature 20°C, stir while adding, drop all Stir and cross-link for 30 minutes after the addition is complete, at this time the mass ratio of chitosan / TPP / KGM is 6 / 1 / 1.2. After cross-linking, centrifu...

Embodiment 2

[0041] Take chitosan in weighing paper and dissolve it in 1% acetic acid solution at room temperature, and obtain a chitosan solution with a mass fraction of 0.3% under magnetic stirring; weigh TPP powder and dissolve it in water to obtain a concentration of 3.3mg / ml of TPP solution; weigh KGM in a beaker, slowly add double distilled water with vigorous stirring to obtain a KGM solution with a concentration of 1 mg / ml. Weigh 0.5g CPP-Ca 2+ The complex is dissolved in a Tris-HCl buffer solution with a pH of 7.4 and 20 mmol / L to obtain a core material solution with a concentration of 50 mg / ml. Mix 0.6ml of TPP solution with 2.4ml of KGM solution, then add 1ml of core material solution, add the mixture of these three substances into 6ml of chitosan solution drop by drop at room temperature 20°C, stir while adding, drop all Stir and cross-link for 30 minutes after the addition is complete, at this time the mass ratio of chitosan / TPP / KGM is 6 / 1 / 1.2. After cross-linking, centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com