Low-cost emulsifying agent applied to oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid, low-cost technology, applied in the field of oil drilling fluid, can solve the problems of increasing the difficulty and cost of on-site operation, unfavorable drilling fluid system stability, lower demulsification voltage, etc., and achieves strong industrial operability and convenience. Promotion and application, the effect of high demulsification voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

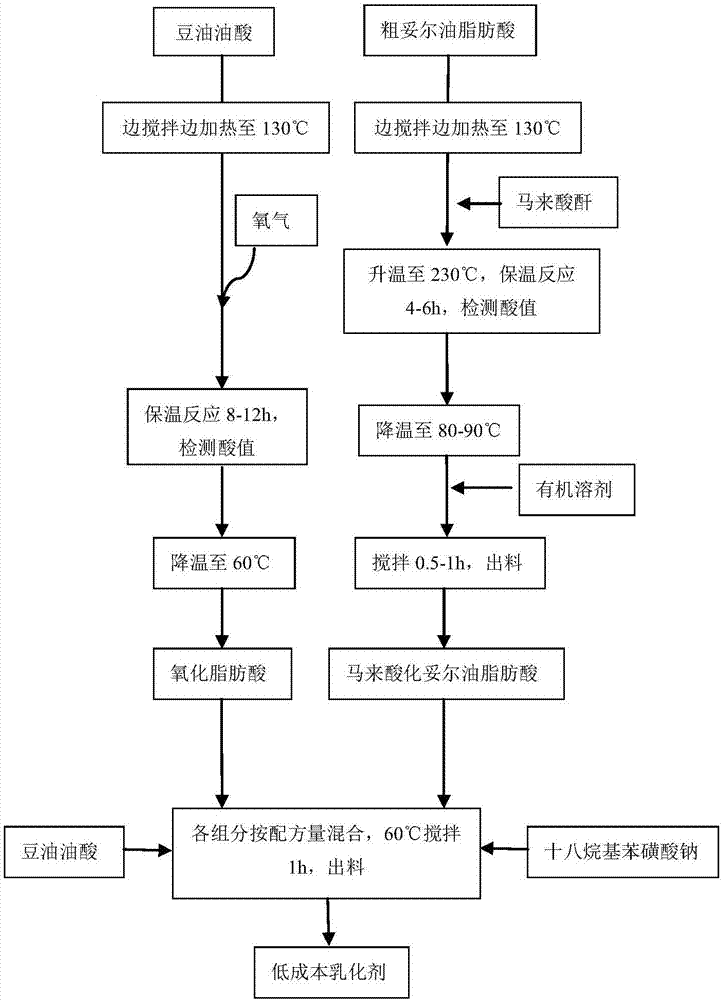

[0032] like figure 1 Shown, be a kind of preparation method of the low-cost emulsifier that is applied to oil-based drilling fluid of the present invention, it may further comprise the steps:

[0033] A. Preparation of oxidized fatty acid: Add fatty acid into the reaction kettle, heat to 120-130°C while stirring, feed air or oxygen at a gas rate of 1-7L / h, keep warm for 8-12 hours, and keep it warm for 8-12 hours. Measure the acid value of the material for 2 hours until the acid value is <170mgKOH / g; cool the temperature of the material to 60°C, and discharge the material to obtain oxidized fatty acid;

[0034] B. Preparation of maleated tall oil fatty acid: add crude tall oil fatty acid to the reactor, and heat to 130-150°C while stirring; add maleic anhydride to the reactor, and heat rapidly so that the temperature of the reactor rises to 230°C, heat preservation reaction for 4~6h, measure the acid value of the material every 1h during the reaction process, until the acid v...

Embodiment 1

[0040] Embodiment 1: the preparation of low-cost emulsifier

[0041] A low-cost emulsifier applied to oil-based drilling fluid and its preparation method. Based on the total mass of the emulsifier as 100%, the composition of the emulsifier includes: 70% of oxidized fatty acid, 15% of maleated tall oil fatty acid %, oleic acid 13%, sodium octadecylbenzenesulfonate 2%.

[0042] The above-mentioned components are prepared according to the following steps:

[0043] A. Preparation of oxidized fatty acid: to 10m 3 Add 5t of soybean oil oleic acid into the reaction kettle, start stirring, heat with heat transfer oil, and heat the soybean oil oleic acid to 130°C while stirring; feed oxygen through the vent pipe at the bottom of the reaction kettle, keep the gas velocity at 4L / h, and maintain the temperature React for 8 to 12 hours; during the reaction process, take samples every 2 hours to measure the acid value of the material, until the acid value <170mgKOH / g, the reaction is over...

Embodiment 2

[0046] Embodiment 2: the preparation of low-cost emulsifier

[0047] A low-cost emulsifier applied to oil-based drilling fluid. Based on the sum of the mass percentages of the emulsifier being 100%, the composition of the emulsifier includes: 45% oxidized fatty acid, 30% maleated tall oil fatty acid, Animal oleic acid 20%, sodium octadecylbenzene sulfonate 5%.

[0048] In this example, the oxidized fatty acid is a reaction product obtained by reacting tallow oleic acid with air through heating; the maleated tall oil fatty acid is obtained by reacting crude tall oil fatty acid and maleic anhydride in a mass ratio of 3:1 product.

[0049] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com