A compound probiotic decomposing agent and its preparation method and application

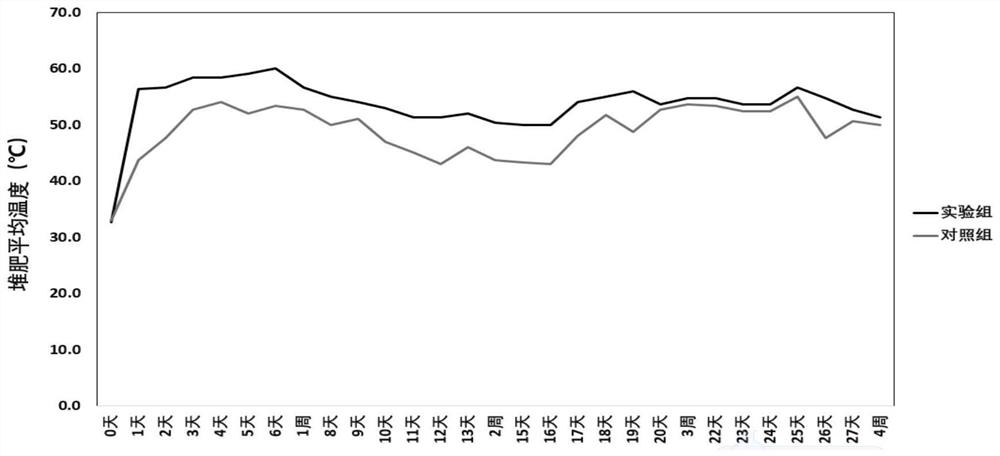

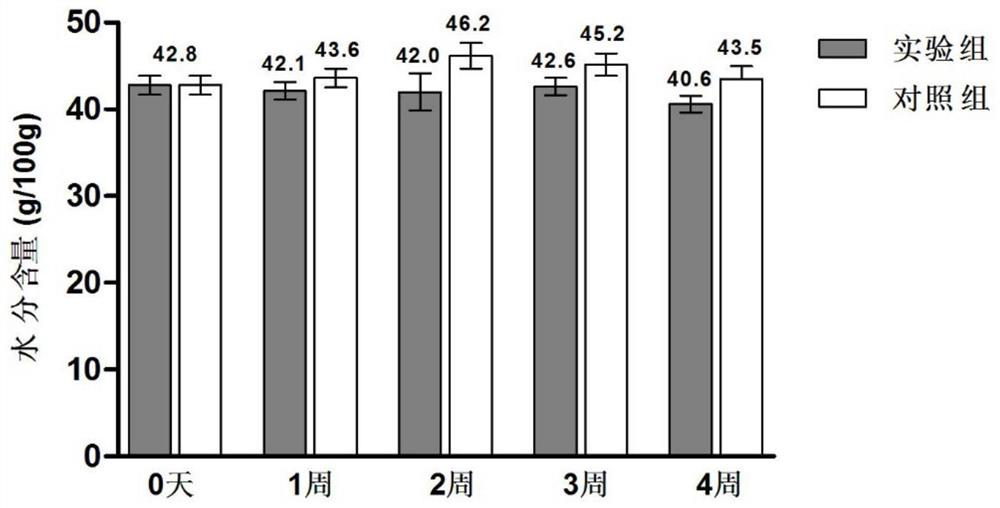

A technology of compounding probiotics and decomposing agent is applied in the biological field, which can solve the problems of low nitrogen content in manure and inability to disperse the heat of manure in time, and achieve the effects of reducing the total number of bacterial colonies, increasing the germination rate and diluting odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Preparation of Lactobacillus plantarum C2, Bacillus subtilis HM-66, Lactobacillus plantarum P-8, Bacillus licheniformis BL-S and preparation of compound probiotic decomposing agent

[0054] In step 1, Lactobacillus plantarum C2, Bacillus subtilis, Lactobacillus plantarum and Bacillus licheniformis are respectively subjected to primary fermentation to obtain corresponding primary seed culture solutions.

[0055] The fermentation conditions of the primary fermentation include: Lactobacillus plantarum C2, Bacillus subtilis, Lactobacillus plantarum and Bacillus licheniformis respectively inoculum 2%-10% (v / v), temperature 33-37°C, rotating speed 50-100r / Cultivate under the condition of m for 18-24h; preferably, cultivate for 20-22h under the conditions of inoculum size 5%-8% (v / v), temperature 35-36°C, and rotation speed 60-80r / m.

[0056] The number of effective viable bacteria of Lactobacillus plantarum C2 in the first-level seed culture solution is ≥ 2×10 9 CFU / g, effe...

Embodiment 2

[0109] Embodiment 2 Preparation of compound lactic acid probiotics

[0110] According to the same method as in Example 1, the four strains of Lactobacillus plantarum C2, Bacillus subtilis HM-66, Lactobacillus plantarum P-8, and Bacillus licheniformis BL-S were respectively subjected to primary, secondary seed cultivation, and tertiary seed cultivation. Fermentation culture, respectively centrifuged to obtain the bacterial cells of these four strains, respectively mixed the bacterial cells with the protective agent solution according to the mass ratio of 1:5, 1:8, 1:5, 1:10 to obtain the bacterial suspension, and the The bacterial suspension was freeze-dried to obtain bacterial agents respectively; the bacterial agents of Lactobacillus plantarum C2, Bacillus subtilis HM-66, Lactobacillus plantarum P-8, and Bacillus licheniformis BL-S were The ratio of 1:1:1:2 is mixed, and the dilution carrier is added for compounding to obtain a compound probiotic decomposing agent, and the to...

Embodiment 3

[0111] Embodiment 3 Preparation of compound lactic acid probiotics

[0112] According to the same method as in Example 1, the four strains of Lactobacillus plantarum C2, Bacillus subtilis HM-66, Lactobacillus plantarum P-8, and Bacillus licheniformis BL-S were respectively subjected to primary, secondary seed cultivation, and tertiary seed cultivation. Fermentation culture, respectively centrifuged to obtain the cells of these four strains of bacteria, the cells were mixed with the protective agent solution according to the mass ratio of 1:7, 1:10, 1:5, 1:8 to obtain a bacterial suspension, and the The bacterial suspension was freeze-dried to obtain bacterial agents respectively; the bacterial agents of Lactobacillus plantarum C2, Bacillus subtilis HM-66, Lactobacillus plantarum P-8, and Bacillus licheniformis BL-S were The ratio of 1:4:1:6 is mixed, and the dilution carrier is added for compounding to obtain a compound probiotic decomposing agent, and the total number of viab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com