Device for direct conversion of atomic thermal energy into electrical energy

An atomic and thermal energy technology, applied in the field of thermal energy conversion, can solve problems such as limited application area and direction, limited heat conversion rate, and limited lifespan, and achieve the effects of subsequent pollution, energy saving, environmental protection, low maintenance costs, and reduced capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Attached below figure 1 to attach Figure 5 The present invention will be further described.

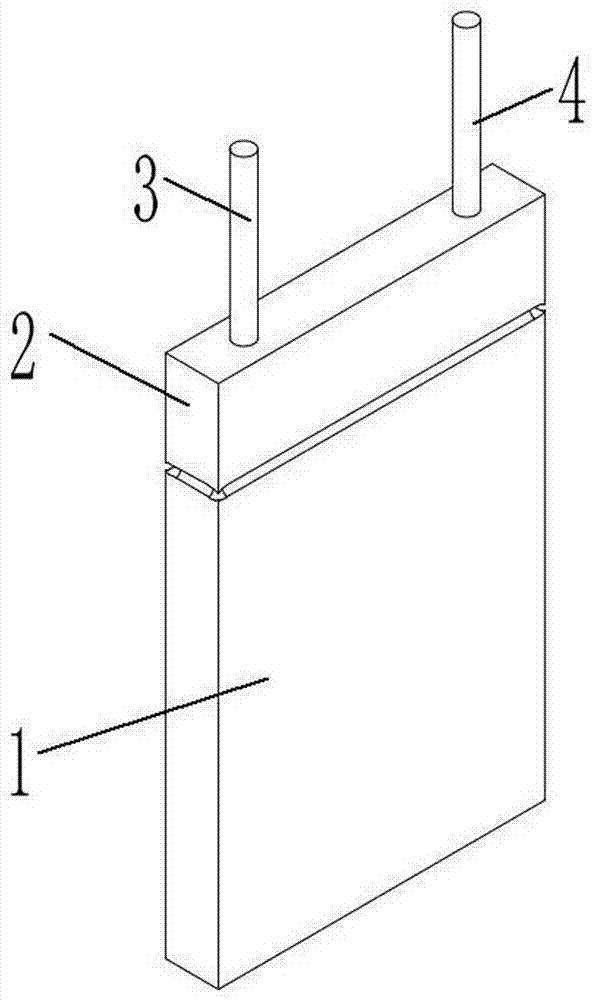

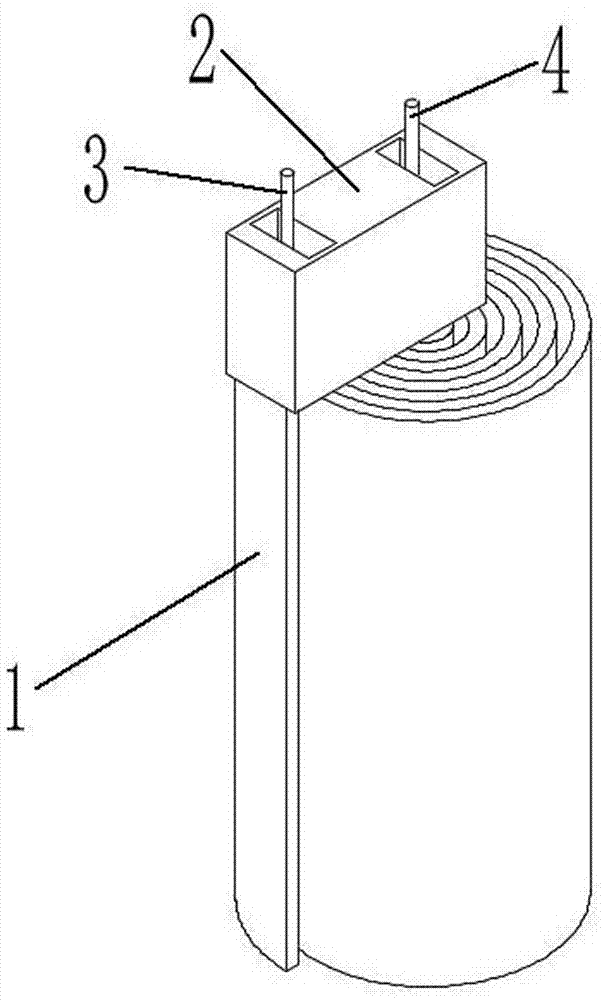

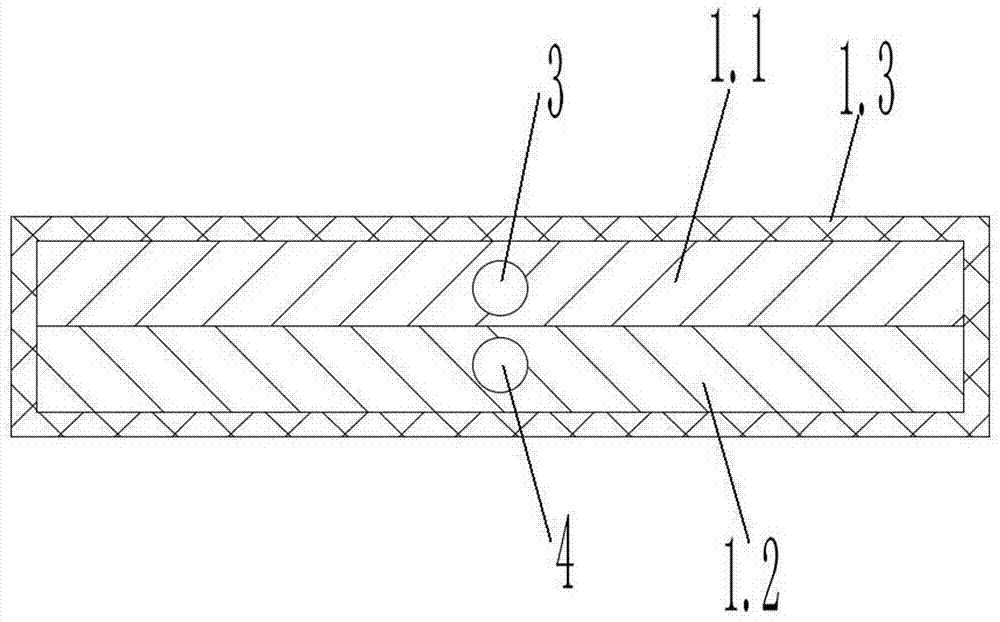

[0035] as attached figure 1 And attached image 3 As shown, a device for directly converting atomic thermal energy into electrical energy includes: an electrogenic base 1, which is composed of several layered negative electric energy atomic material layers 1.1 and several layered ionization energy atomic material layers 1.2. The electric energy atomic substance layer 1.1 is made of graphene material, the ionization energy atomic substance layer 1.2 is made of titanium alloy material, the negative electric energy atomic substance layer 1.1 and the ionization energy atomic substance layer 1.2 are sealed and wrapped with a ceramic insulating layer 1.3; electron accelerator 2. It is set on the upper end of the electricity generating base 1, and the electron-guiding fiber I 3 and the electron-guiding fiber II 4 are inserted vertically inside it. The lower end of the electron-gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com