Raspberry-like shaped microsphere, super-hydrophobic coating and preparation methods thereof

A super-hydrophobic coating, raspberry-like technology is applied in the field of synthesis of raspberry-like polymethyl methacrylate/silicon dioxide composite materials, which can solve the limitation, the size of super-hydrophobic composite particles is difficult to control, and the application is difficult. and other problems, to achieve the effects of size controllable, good chemical stability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

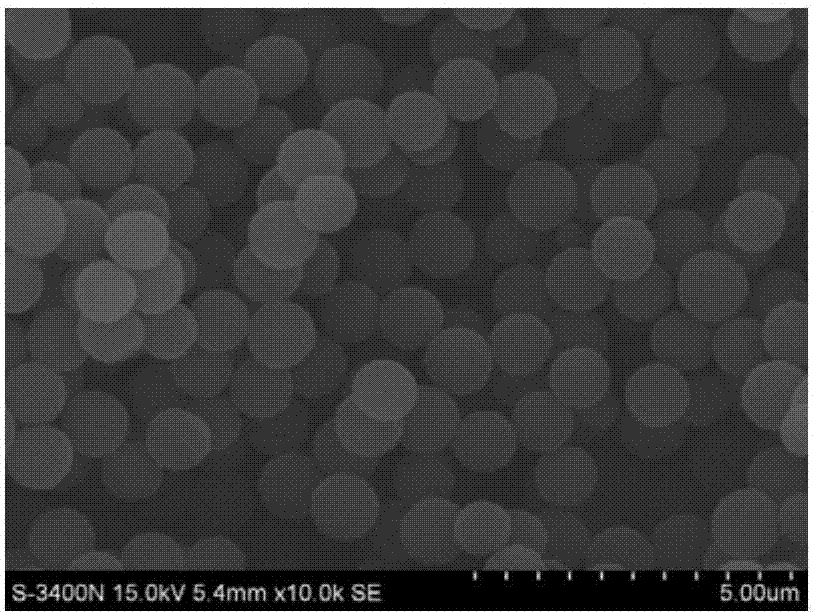

[0031] a. Synthesis of polymethyl methacrylate microspheres

[0032] Disperse 3.5g of polyvinylpyrrolidone in methanol / water (70ml / 30ml) solvent, blow nitrogen gas for 30min to remove oxygen, heat at 55°C and stir for 3h. A mixture of 9.5 g of methyl methacrylate and 0.1 g of azobisisobutyronitrile was added dropwise to the polyvinylpyrrolidone dispersion. Slowly raise the temperature to 70°C, react for 24 hours, centrifuge, wash, and dry at 60°C for 12 hours to obtain polymethylmethacrylate microspheres.

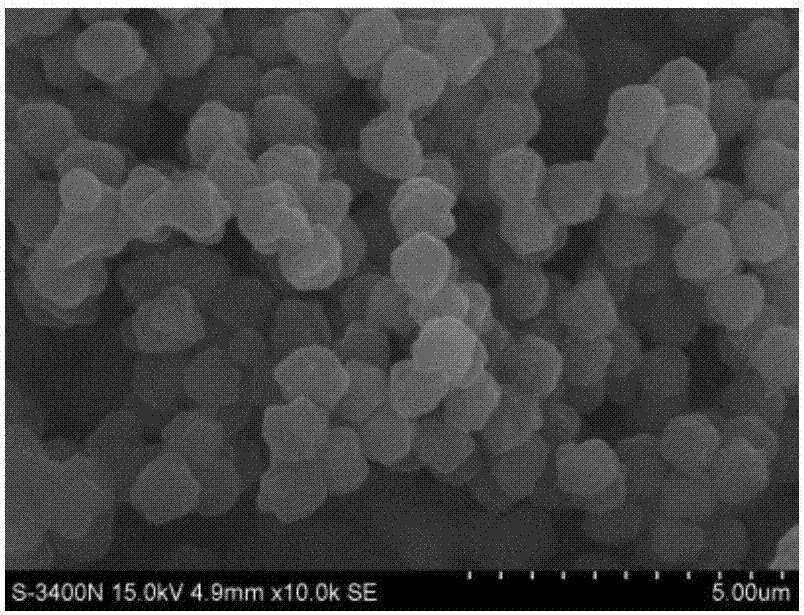

[0033] b. Synthesis and hydrophobic treatment of raspberry-like PMMA / silica composite microspheres

[0034] Take 7.9 g of polymethyl methacrylate microspheres synthesized in a above, add tetraethyl orthosilicate ethanol solution (tetraethyl orthosilicate 0.0018 g, ethanol 90 ml), add ammonia water to adjust the pH value to 11.3, and react at room temperature 12h, synthesize raspberry-like polymethylmethacrylate / silica composite microspheres. At the same time, the polymet...

Embodiment 2

[0038] a. Synthesis of polymethyl methacrylate microspheres

[0039] Disperse 3.5g of polyvinylpyrrolidone in methanol / water (70ml / 30ml) solvent, blow nitrogen gas for 30min to remove oxygen, heat and stir at 60°C for 3h. A mixture of 10 g of methyl methacrylate and 0.4 g of azobisisobutyronitrile was added dropwise to the polyvinylpyrrolidone dispersion. Slowly raise the temperature to 70°C, react for 24 hours, centrifuge, wash, and dry at 60°C for 12 hours to obtain polymethylmethacrylate microspheres.

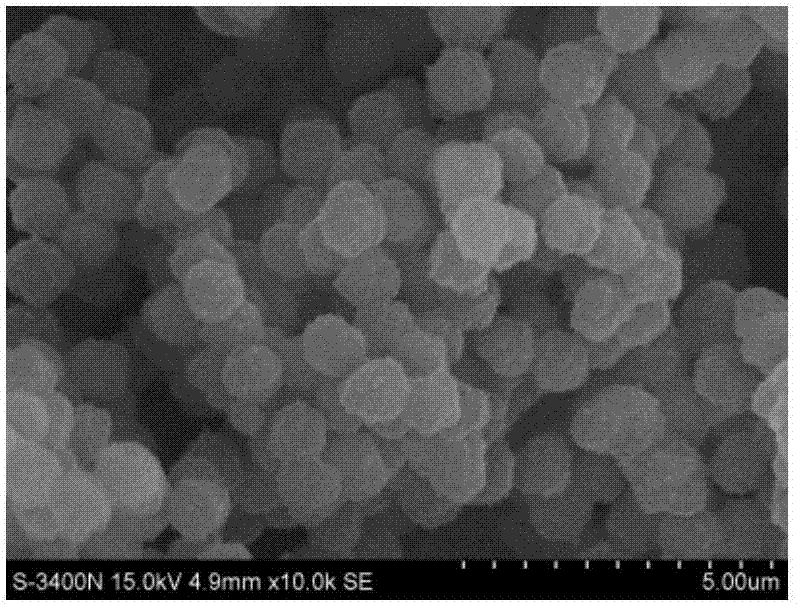

[0040] b. Synthesis and hydrophobic treatment of raspberry-like PMMA / silica composite microspheres

[0041] Take 8.5 g of polymethyl methacrylate microspheres synthesized in a above, add tetraethyl orthosilicate ethanol solution (tetraethyl orthosilicate 0.0018g, ethanol 90ml), add ammonia water to adjust the pH value to 11.3, and react at room temperature 12h, synthesize raspberry-like polymethylmethacrylate / silica composite microspheres. At the same time, the polymethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com