Preparation method of small-size high-stability perovskite nanocrystalline Cs4PbBr6

A high-stability, perovskite technology, applied in the field of synthesis of Cs4PbX6 perovskite nanocrystals, can solve the problems of poor monodispersity and stability, cannot be obtained, and is not ideal enough to achieve good stability and regular morphology , the effect of rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First, a cesium oleate solution is prepared. Take 2mmol (0.6516g) of cesium carbonate powder, 8.78mmol (2.5mL) of OA (oleic acid) and 17.5mL of ODE (octadecene) and mix them, heat to 150°C under nitrogen protection to dissolve cesium carbonate, and prepare 0.2mol / L cesium oleate solution is light yellow and transparent. Take out the cesium carbonate solution while it is hot and set aside. Since the cesium carbonate octadecene solution will solidify below 100°C, it needs to be heated to 100°C to dissolve it before each use.

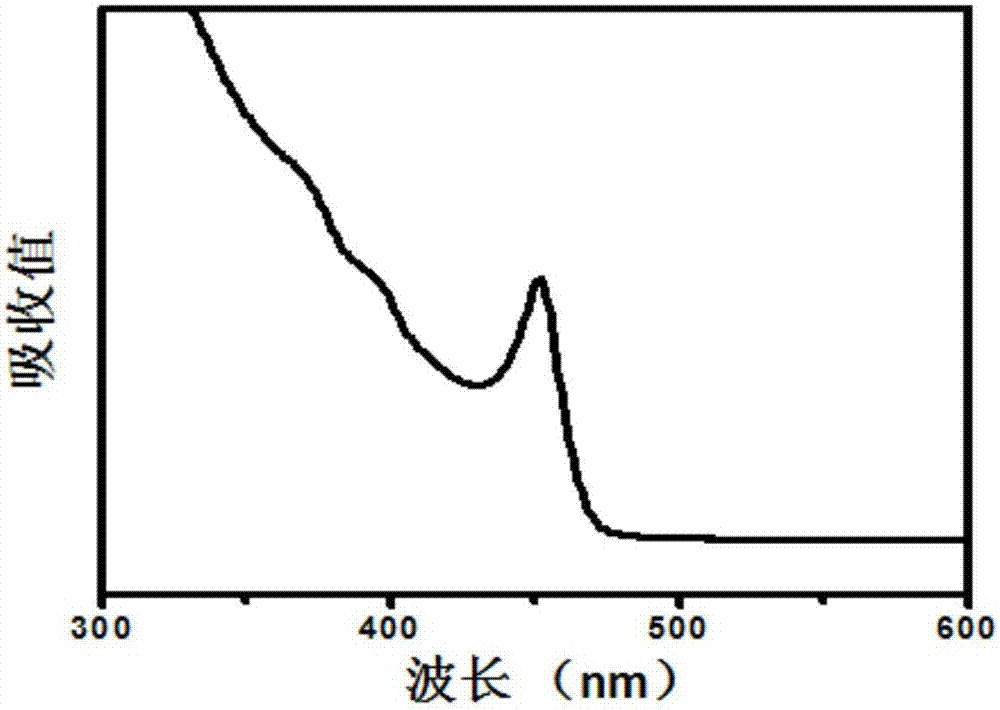

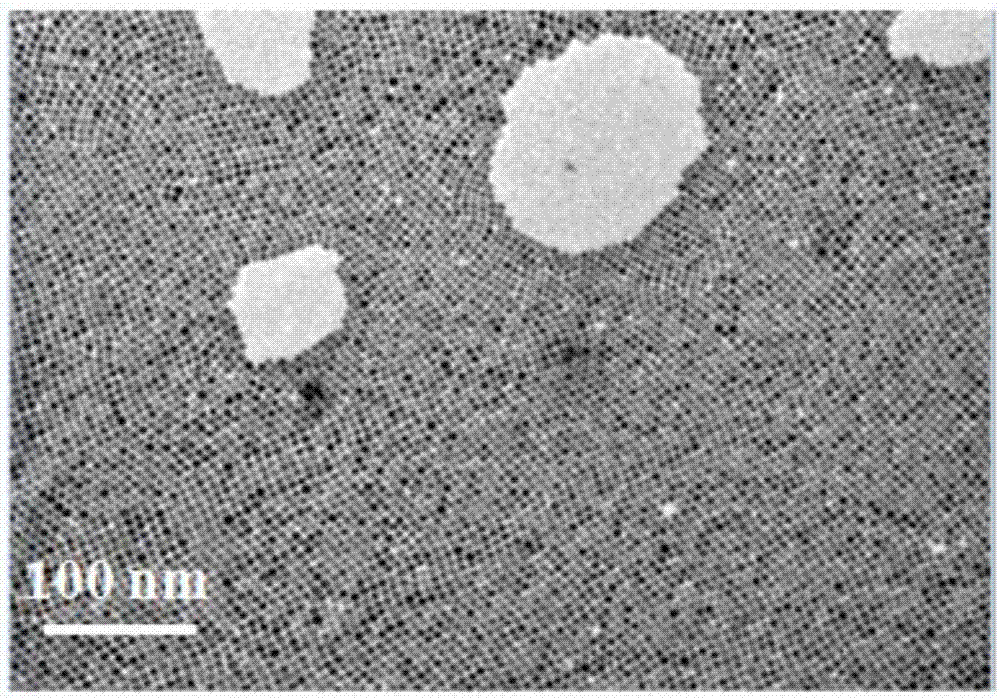

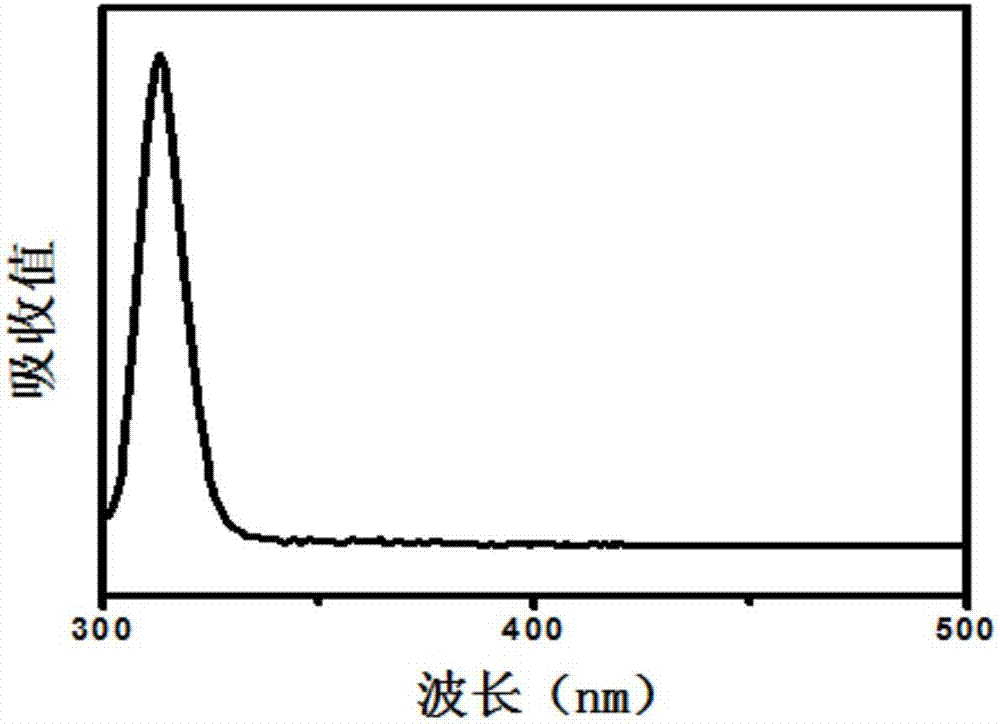

[0028] Then take 0.2mmol of lead bromide solid powder, 0.5mL of oleylamine, 0.5mL of oleic acid and 3mL of octadecene into a three-necked flask, vacuumize at 120°C for 30 minutes, fill with nitrogen protection, and then heat up to 140°C. After the lead bromide is dissolved, inject 0.2 mL of 0.2 mol / L cesium oleate octadecene solution heated and melted in advance, and react to obtain CsPbBr with an absorption peak at 452 nm (3.8 nm in size) 3 Pero...

Embodiment 2

[0031] First, a cesium oleate solution is prepared. Take 2mmol (0.6516g) of cesium carbonate powder, 8.78mmol (2.5mL) of OA (oleic acid) and 17.5mL of ODE (octadecene) and mix them, heat to 150°C under nitrogen protection to dissolve cesium carbonate, and prepare 0.2mol / L cesium oleate solution is light yellow and transparent. Take out the cesium carbonate solution while it is hot and set aside. Since the cesium carbonate octadecene solution will solidify below 100°C, it needs to be heated to 100°C to dissolve it before each use.

[0032] Then take 0.2mmol of lead bromide solid powder, 0.5mL of oleylamine, 0.5mL of oleic acid and 3mL of octadecene into a three-necked flask, vacuumize at 120°C for 30 minutes, fill with nitrogen protection, and then heat up to 140°C. After the lead bromide is dissolved, inject 0.2 mL of 0.2 mol / L cesium oleate octadecene solution heated and melted in advance, and react to obtain CsPbBr with an absorption peak at 452 nm (3.8 nm in size) 3 Pero...

Embodiment 3

[0035] First, a cesium oleate solution is prepared. Take 2mmol (0.6516g) of cesium carbonate powder, 8.78mmol (2.5mL) of OA (oleic acid) and 17.5mL of ODE (octadecene) and mix them, heat to 150°C under nitrogen protection to dissolve cesium carbonate, and prepare 0.2mol / L cesium oleate solution is light yellow and transparent. Take out the cesium carbonate solution while it is hot and set aside. Since the cesium carbonate octadecene solution will solidify below 100°C, it needs to be heated to 100°C to dissolve it before each use.

[0036] Then take 0.2mmol of lead bromide solid powder, 0.5mL of oleylamine, 0.5mL of oleic acid and 3mL of octadecene into a three-necked flask, vacuumize at 120°C for 30 minutes, fill with nitrogen protection, and then heat up to 140°C. After the lead bromide is dissolved, inject 0.2 mL of 0.2 mol / L cesium oleate octadecene solution heated and melted in advance, and react to obtain CsPbBr with an absorption peak at 452 nm (3.8 nm in size) 3 Pero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com