PMMA ultrathin hot melt adhesive film as well as production method and application thereof

A technology of hot melt adhesive film and production method, which is applied in the direction of film/sheet adhesive, adhesive, heat activated film/sheet, etc., can solve the problem of high requirements for PMMA equipment, poor weather resistance, poor high temperature resistance, etc. problems, to achieve the effect of highlighting aging resistance, eliminating volatile corrosion, and reducing equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

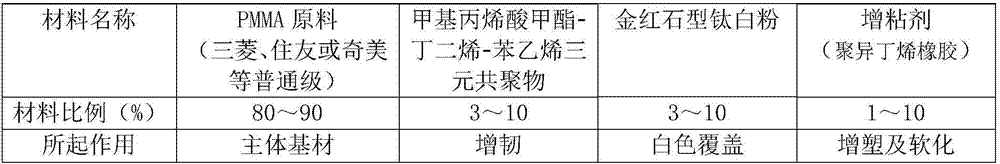

[0032] A PMMA ultra-thin hot-melt adhesive film is composed of 80KG PMMA, 5KG methyl methacrylate-butadiene-styrene terpolymer, 5KG rutile titanium dioxide, and 10KG polyisobutylene rubber raw material components.

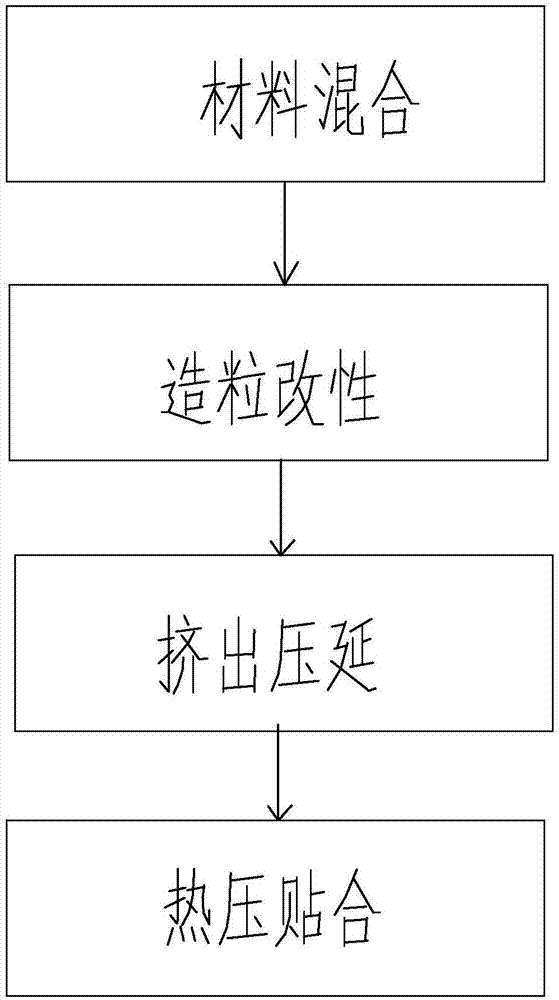

[0033] Its preparation method is:

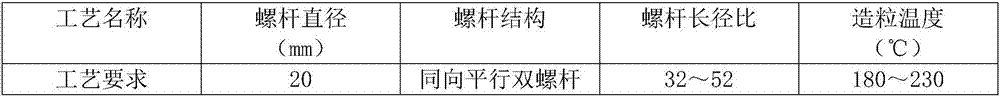

[0034]Mix the above raw material components to obtain a mixture; put the mixture into the mixing chamber of the granulator, the granulator adopts co-rotating parallel twin-screws, the screw diameter is 20mm, the screw length-to-diameter ratio is 32:1, and the granulation temperature is 180°C , made into granules through a granulator; the granules are extruded through a single-screw extruder, and calendered by a calender to produce an ultra-thin, flexible, folding-resistant and high-weather-resistant environmental protection product with a thickness of 0.05mm. Type hot melt adhesive film. It is required that the drying temperature is 80°C, the drying time is 6h, the screw temperature is 220°C, the conveying section temperature is...

Embodiment 2

[0037] A PMMA ultra-thin hot-melt adhesive film is composed of PMMA 90KG, methyl methacrylate-butadiene-styrene terpolymer 3KG, rutile titanium dioxide 3KG, polyisobutylene rubber 4KG raw material components.

[0038] Its preparation method is:

[0039] Mix the above raw material components to obtain a mixture; put the mixture into the mixing chamber of the granulator, the granulator adopts co-rotating parallel twin-screws, the screw diameter is 20mm, the screw length-to-diameter ratio is 52:1, and the granulation temperature is 230°C , made into granules through a granulator; the granules are extruded through a single-screw extruder, calendered and formed by a calender to produce an ultra-thin 0.08mm-thick, mirror-surfaced on both sides, with a certain degree of flexibility and folding resistance And high weather resistance environment-friendly hot melt adhesive film. It is required that the drying temperature is 100°C, the drying time is 4h, the screw temperature is 240°C, ...

Embodiment 3

[0042] A PMMA ultra-thin hot-melt adhesive film is composed of PMMA 85KG, methyl methacrylate-butadiene-styrene terpolymer 10KG, rutile titanium dioxide 4KG, and tackifier 1KG raw material components.

[0043] Its preparation method is:

[0044] Mix the above raw material components to obtain a mixture; put the mixture into the mixing chamber of the granulator, the granulator adopts co-rotating parallel twin-screws, the screw diameter is 25mm, the screw length-to-diameter ratio is 35:1, and the granulation temperature is 200°C , made into granules through a granulator; the granules are extruded through a single-screw extruder, calendered and formed by a calender to produce an ultra-thin 0.08mm-thick, mirror-surfaced on both sides, with a certain degree of flexibility and folding resistance And high weather resistance environment-friendly hot melt adhesive film. The drying temperature is required to be 100°C, the drying time is 4h, the screw temperature is 230°C, the conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com