Plunger pump return stroke disk

A technology of return plate and plunger pump, which is applied in the direction of coating, furnace type, furnace, etc., can solve the problems of excessive return plate, non-wear resistance, and low hardness of plunger pumps, so as to ensure machining accuracy and improve wear resistance , the effect of less deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

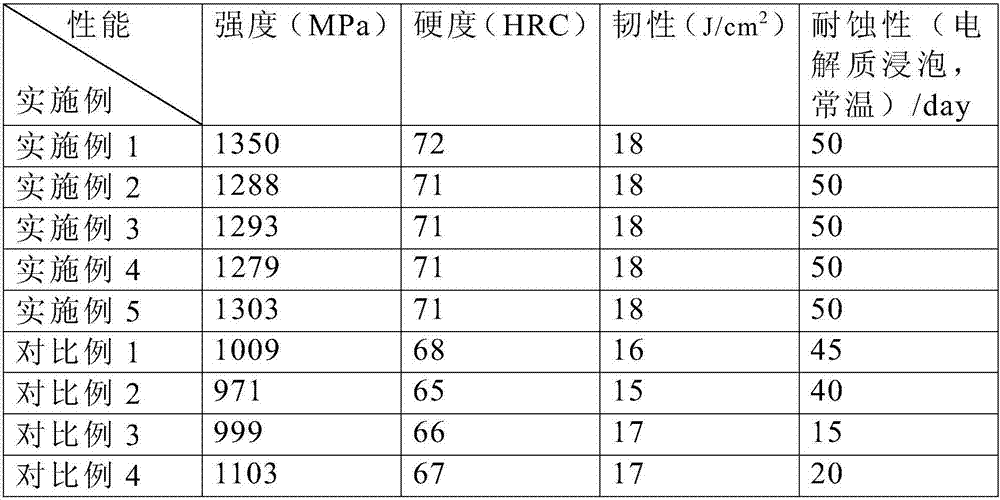

Examples

Embodiment 1

[0037] Ingredients: Weigh the raw materials according to the composition and mass percentage of the return plate of the plunger pump, including Nb: 0.03%, Al: 0.3%, C: 0.2%, Cr: 0.3%, Mo: 0.2%, Ti: 0.08%, Rare earth: 0.03%, N: 0.009%, the balance is Fe and impurities, wherein rare earth is one or more of Y, Sm, Ho, and impurities include P<0.004%, S<0.004%, O<0.002%. The raw materials except Al, N, Ti and rare earth are melted to form alloy liquid.

[0038] Self-deoxidation: The aluminum is ground into aluminum powder with a particle size of 400nm. First, half of the aluminum powder is added to the alloy solution for pre-deoxidation, and then the remaining aluminum powder is added for re-deoxidation.

[0039] Pulverizing: First, nitrogen and titanium are directly reacted at high temperature to obtain titanium nitride, and titanium nitride and rare earth are air-milled into powder with a particle size of 400 nm and mixed into powder.

[0040] Pouring: first spread the mixed po...

Embodiment 2

[0044] Ingredients: Weigh the raw materials according to the composition and mass percentage of the return plate of the plunger pump, including Nb: 0.02%, Al: 0.2%, C: 0.1%, Cr: 0.2%, Mo: 0.1%, Ti: 0.06%, Rare earth: 0.01%, N: 0.008%, the balance is Fe and impurities, wherein rare earth is one or more of Y, Sm, Ho, and impurities include P<0.004%, S<0.004%, O<0.002%. The raw materials except Al, N, Ti and rare earth are melted to form alloy liquid.

[0045] Self-deoxidation: The aluminum is ground into aluminum powder with a particle size of 400nm. First, half of the aluminum powder is added to the alloy solution for pre-deoxidation, and then the remaining aluminum powder is added for re-deoxidation.

[0046] Pulverizing: First, nitrogen and titanium are directly reacted at high temperature to obtain titanium nitride, and titanium nitride and rare earth are air-milled into powder with a particle size of 400 nm and mixed into powder.

[0047] Pouring: first spread the mixed po...

Embodiment 3

[0051] Ingredients: Weigh the raw materials according to the composition of the plunger pump return plate and its mass percentage, including Nb: 0.04%, Al: 0.4%, C: 0.3%, Cr: 0.4%, Mo: 0.3%, Ti: 0.1%, Rare earth: 0.05%, N: 0.01%, the balance is Fe and impurities, wherein rare earth is one or more of Y, Sm, Ho, and impurities include P<0.004%, S<0.004%, O<0.002%. The raw materials except Al, N, Ti and rare earth are melted to form alloy liquid.

[0052] Self-deoxidation: The aluminum is ground into aluminum powder with a particle size of 400nm. First, half of the aluminum powder is added to the alloy solution for pre-deoxidation, and then the remaining aluminum powder is added for re-deoxidation.

[0053] Pulverizing: First, nitrogen and titanium are directly reacted at high temperature to obtain titanium nitride, and titanium nitride and rare earth are air-milled into powder with a particle size of 400 nm and mixed into powder.

[0054] Pouring: first spread the mixed powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com