Preparation method of flexible transparent electrode

A transparent electrode, flexible technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of nano-silver wire conductivity and transmittance decrease, increase the electric field distance in LCD, increase the thickness of LCD box, etc. Achieve the effect of improving product reliability, simplifying the process, and reducing equipment and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

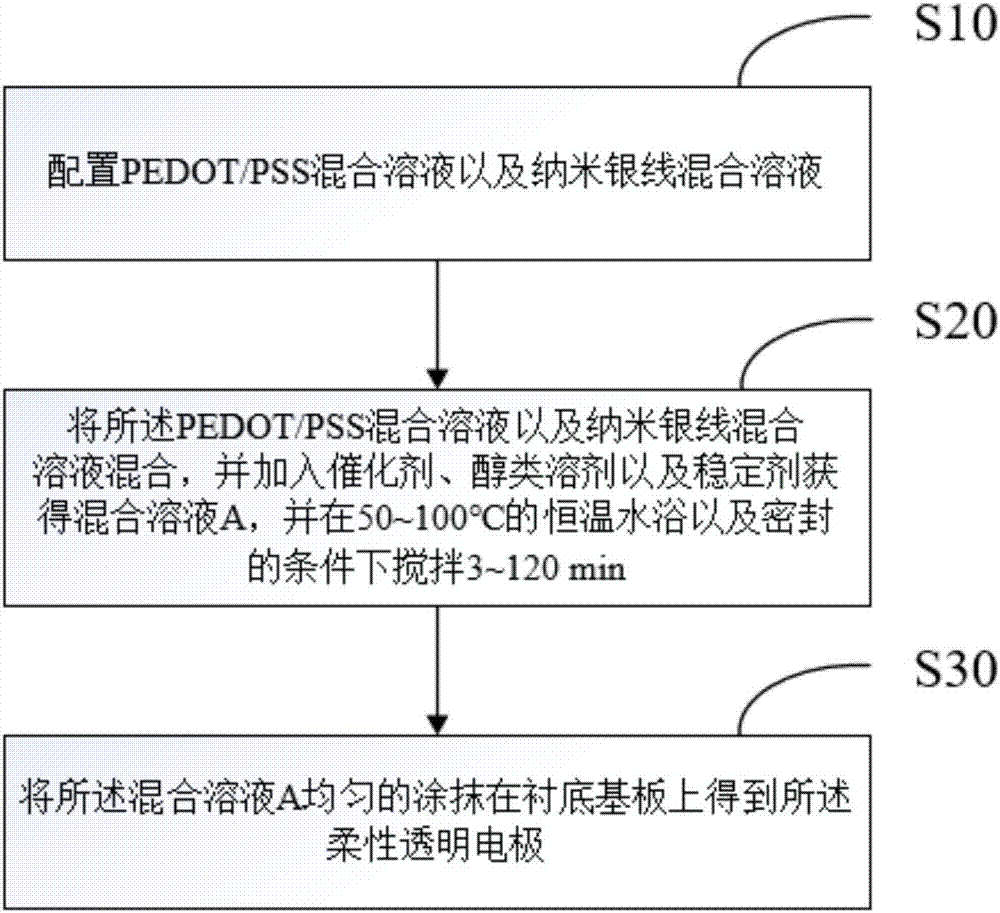

Image

Examples

Embodiment Construction

[0033] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as [top], [bottom], [front], [back], [left], [right], [inside], [outside], [side], etc., are only for reference The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention. In the figures, structurally similar elements are denoted by the same reference numerals.

[0034] The invention provides a method for preparing a flexible transparent electrode, because traditional transparent electrode materials need to be coated with a protective layer to isolate the contact between oxygen and nano-silver wires, and the existence of the protective layer limits the use of nano-silver wires in certain fields. Applications, such as replacing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com