Ammonia desulfurization process and desulfurization device thereof

An ammonia desulfurization and process technology, applied in the field of desulfurization, can solve the problems of low chemical reaction speed, high desulfurization cost, occupation of desulfurization tower, etc., to avoid secondary pollution, prevent ammonia escape, and save floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

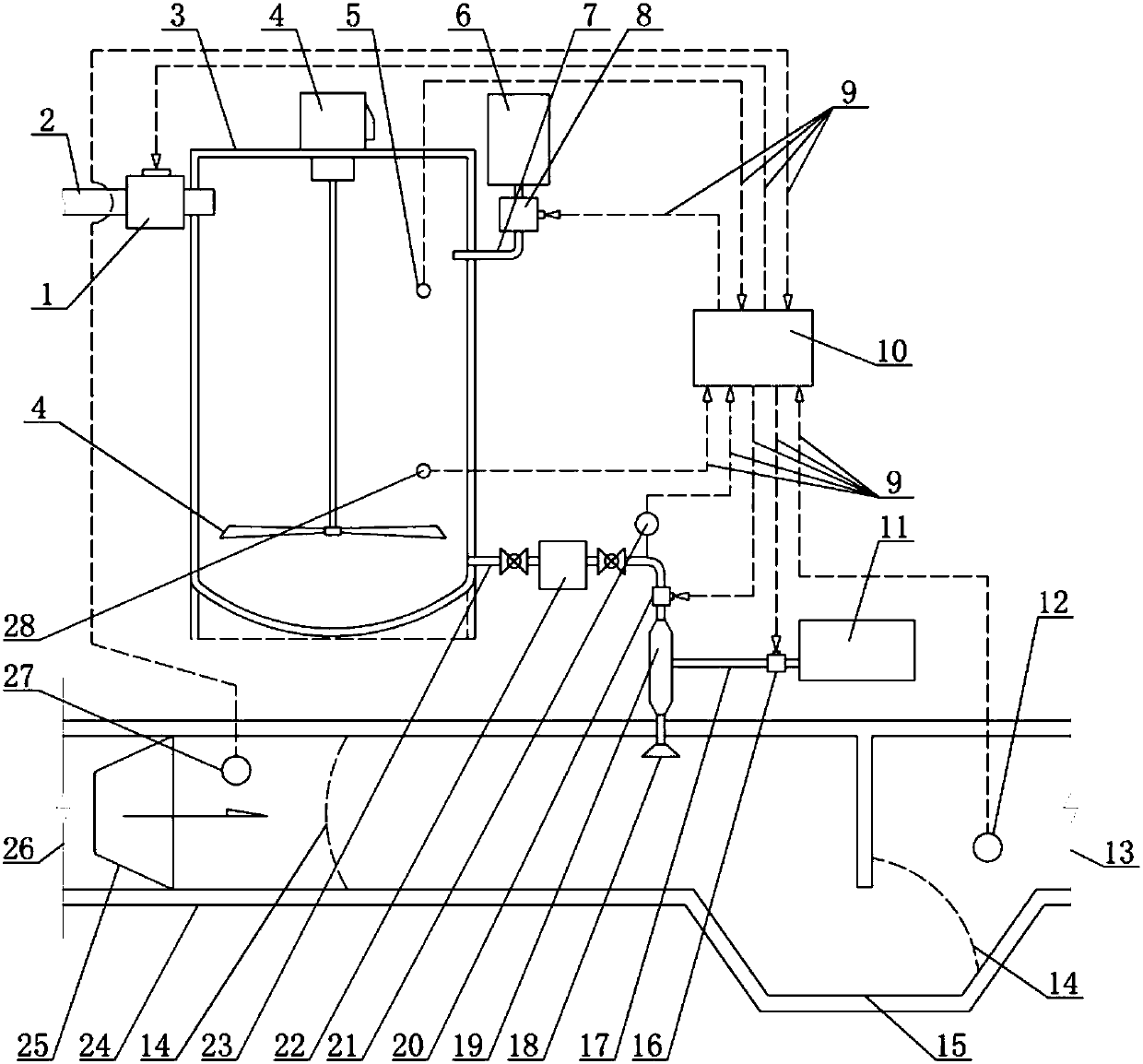

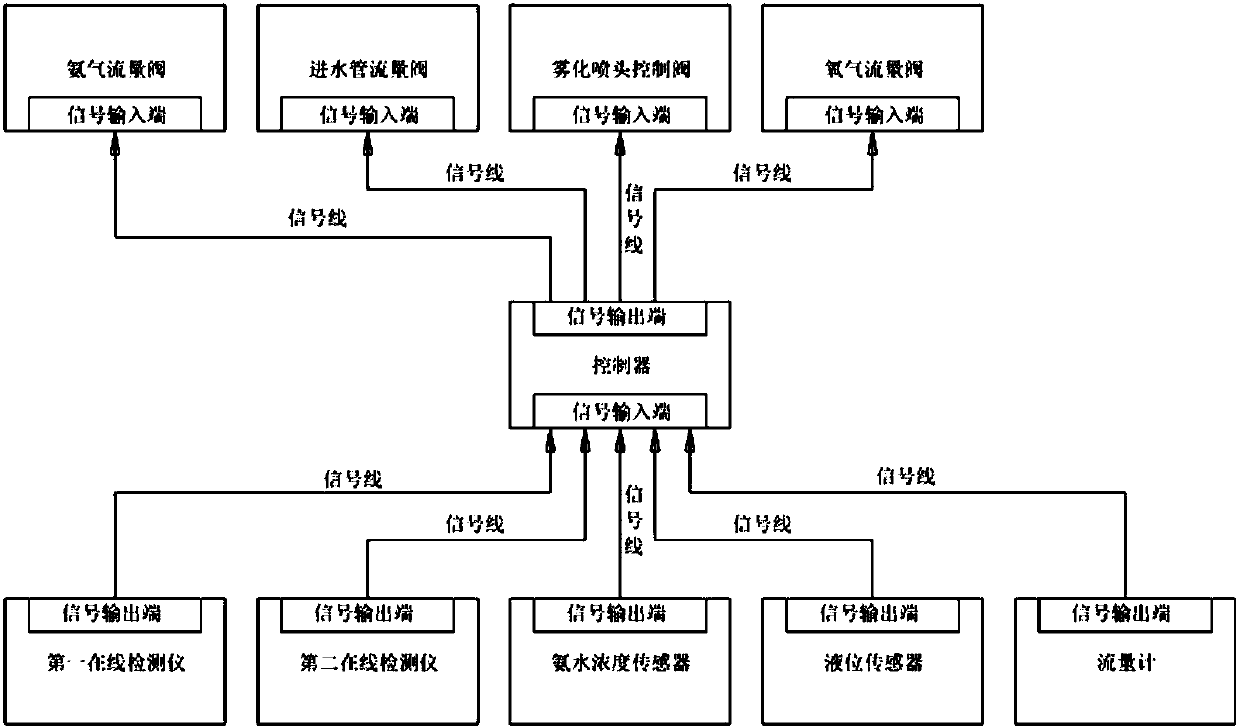

[0023] The ammonia desulfurization device of the present invention comprises a flue 24, a liquid storage tank 3, an oxygen tank 11, a product collection device 15, a first on-line detector 27 is installed at the inlet of the reaction zone 14 in the flue, and an outlet of the reaction zone 14 The second on-line detector 12 is installed, and the inner wall of the flue between the first and second on-line detectors is equipped with an atomizing nozzle 18. The nozzles of the atomizing nozzle are one or more at different angles, which can make the desulfurization sprayed When the agent is added, a disturbance state can be formed in the flue, which is conducive to full mixing. The flue refers to the boiler flue, and can also be the waste gas passage of equipment containing sulfur dioxide waste gas. The position of the reaction zone is near the outlet of the induced draft fan 25 in the flue or waste gas passage. The inlet of the atomizing nozzle 18 communicates with the outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com