Method for disposing BDO (1,4-butanediol) waste liquid by recycling

A technology of recycling and waste liquid, applied in chemical instruments and methods, natural water treatment, water/sewage treatment, etc., can solve the problem that the waste liquid of BDO process cannot be recycled, and achieve resource regeneration, strong operability, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

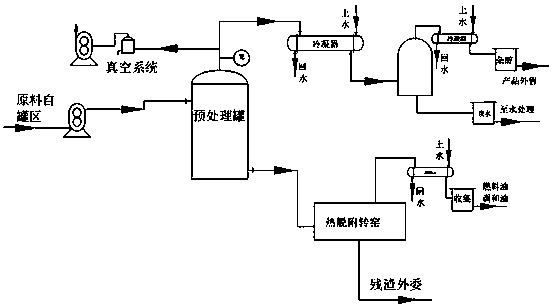

Image

Examples

Embodiment 1

[0023] Taking the BDO process waste liquid of a factory as an example, the basic composition of the process waste liquid is 5% low-boiling alcohol, 40% high-boiling alcohol, 40% salt, 5% water, and 10% other. The process of disposal is as follows:

[0024] 1. Pump the BDO process waste liquid to the pretreatment tank, separate and remove a small amount of low boiling matter and water, use vacuum distillation, adopt a vacuum degree of 50KPa, control the temperature at the top of the tower at 90°C, and remove low boiling matter and water. After condensation, it enters the intermediate storage tank for centralized collection and treatment, and the waste liquid at the bottom of the distillation tower enters the subsequent cracking device for treatment.

[0025] 2. Send the low boiling matter and water from the intermediate storage tank in step 1 to the rectification tower, raise the temperature to 170°C, and control the reflux ratio to 1.5:1. The high-purity low boiling matter sepa...

Embodiment 2

[0030] A method for resourceful disposal of BDO waste liquid. The BDO waste liquid is composed of the following raw materials in weight percentage: 18% low-boiling point alcohol, 22% high-boiling point alcohol, 15% salt, 20% water, and 25% other. The steps are as follows:

[0031] (1) Put the BDO waste liquid into the distillation tower for vacuum distillation, the vacuum degree is 20 kPa, the temperature at the top of the distillation tower is 60°C, and the low boilers, water and waste liquid at the bottom of the tower are separated;

[0032] (2) Send the low-boiling substances (methanol, ethanol, propanol and butanol) and water separated in step (1) into the rectification tower, raise the temperature to 70°C, and the reflux ratio is 1:1 to separate high-purity low-boiling substances thing;

[0033] (3) Send the waste liquid at the bottom of the tower obtained in step (1) to the thermal desorption rotary kiln. The temperature is controlled at 200°C. Natural gas is used as the...

Embodiment 3

[0036] A method for resourceful disposal of BDO waste liquid. The BDO waste liquid is composed of the following raw materials in weight percentage: 10% low-boiling point alcohol, 15% high-boiling point alcohol, 35% salt, 10% water, and 30% other products. The steps are as follows :

[0037] (1) Put the BDO waste liquid into the distillation tower for vacuum distillation, the vacuum degree is 100 kPa, the temperature at the top of the distillation tower is 80°C, and the low boilers, water and waste liquid at the bottom of the tower are separated;

[0038] (2) Send the low-boiling substances (methanol, ethanol, propanol and butanol) and water separated in step (1) into the rectification tower, raise the temperature to 90°C, and the reflux ratio is 6:1 to separate high-purity low-boiling thing;

[0039] (3) Send the tower bottom waste liquid obtained in step (1) to the thermal desorption rotary kiln. The temperature is controlled at 350°C. Natural gas is used as the heat source ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com