Preparation method of quick-drying type metal anti-corrosion coating

A metal anti-corrosion, quick-drying technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of long surface drying time, insufficient curing, low paint film adhesion, etc., to achieve enhanced hydrophobic performance, It is convenient for water volatilization and has broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

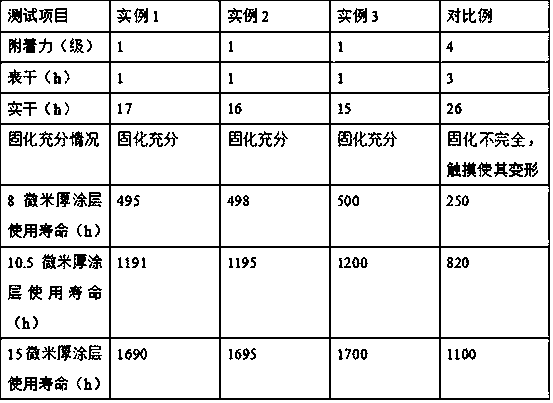

Examples

example 1

[0025]In parts by weight, take 20 parts of beer waste yeast, wash with sterile water, put the cleaned beer waste yeast into a high-speed centrifuge, centrifuge at a speed of 5000r / min for 5min, discard the supernatant, and obtain milky white Yeast milk, mix milky white yeast milk and thyme essential oil at a volume ratio of 1:3 to obtain latex oil, wash the latex oil twice with absolute ethanol, and put the washed latex oil into a vacuum drying oven with a set temperature of 35°C Dry in medium for 3h to obtain essential oil microcapsules; add 50mL soybean oil, 10mL formic acid solution with a mass fraction of 10%, 20mL hydrogen peroxide with a mass fraction of 20% and 30mL mass fraction For a sulfuric acid solution with a fraction of 75%, start the agitator, stir at a speed of 200r / min, heat up to 90°C, and keep it warm for 2.0h to obtain a reaction product, transfer the reaction product into a separatory funnel, wash with water, and discard the water phase , to obtain the oil...

example 2

[0027] In parts by weight, take 25 parts of beer waste yeast, wash with sterile water, put the cleaned beer waste yeast into a high-speed centrifuge, centrifuge at a speed of 5200r / min for 7min, discard the supernatant, and obtain milky white Yeast milk, mix milky white yeast milk and thyme essential oil in a volume ratio of 1:3 to obtain latex oil, wash the latex oil twice with absolute ethanol, and put the washed latex oil into a vacuum drying oven with a set temperature of 40°C Dry in medium for 3.5h to obtain essential oil microcapsules; add 55mL soybean oil, 11mL formic acid solution with a mass fraction of 10%, 22mL hydrogen peroxide with a mass fraction of 20% and 35mL For a sulfuric acid solution with a mass fraction of 75%, start the agitator, stir at a speed of 210r / min, heat up to 92°C, and keep it warm for 2.2 hours to obtain a reaction product. Transfer the reaction product into a separatory funnel, wash with water, and discard the water phase, to obtain the oil p...

example 3

[0029] In parts by weight, take 30 parts of beer waste yeast, wash with sterile water, put the cleaned beer waste yeast into a high-speed centrifuge, centrifuge at a speed of 5500r / min for 8min, discard the supernatant, and obtain milky white Yeast milk, mix the milky white yeast milk and thyme essential oil in a volume ratio of 1:3 to obtain latex oil, wash the latex oil with absolute ethanol for 3 times, and put the washed latex oil into a vacuum drying oven with a set temperature of 45°C Dry in medium for 4h to obtain essential oil microcapsules; add 60mL of soybean oil, 12mL of formic acid solution with a mass fraction of 10%, 25mL of hydrogen peroxide with a mass fraction of 20% and 40mL of For a sulfuric acid solution with a fraction of 75%, start the agitator, stir at a speed of 220r / min, heat up to 95°C, and keep the temperature for 2.5h to obtain the reaction product, transfer the reaction product into a separatory funnel, wash with water, and discard the water phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com