Shear-resistant low-concentration guar gum zirconium gel fracturing fluid

A gel fracturing fluid, low-concentration technology, applied in the direction of production fluid, wellbore/well components, drilling composition, etc., can solve the problems of irreversible cross-linking process, high shear resistance, high temperature resistance, etc. , to achieve the effect of improving stability, good suspended sand performance and low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

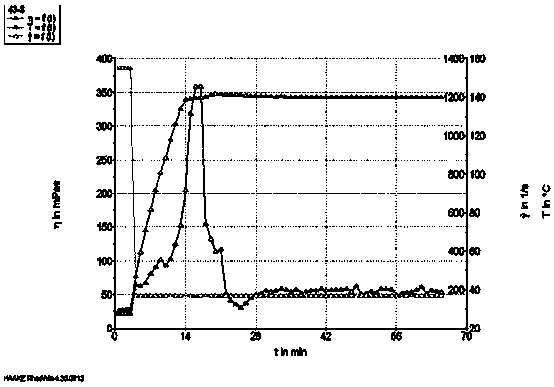

[0042] Example 1 Preparation of organozirconium crosslinking agent tetrakis(triethanolamine) zirconate

[0043] Add 12g of tetra-n-propyl zirconate into a three-necked flask, start stirring, add 7.5g of triethanolamine and 7.5g of n-propanol, heat to 60°C, and react for 2 hours; during heating, a white solid is produced; after adding 1g of water, the solid dissolves, Then heated to 80°C and reacted for 4h to obtain a yellow liquid containing 12% zirconium.

Embodiment 2

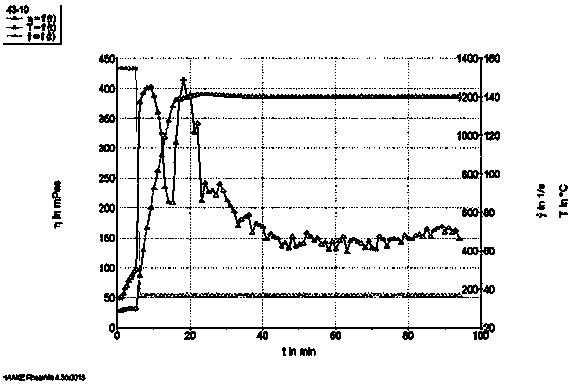

[0044] Example 2 Preparation of water-based zirconium crosslinking agent (zirconium and complexing agent form a polynuclear hydroxyl bridge structure in water)

[0045] Take 10g of zirconium oxychloride and add it into a three-necked flask, add 40g of water at the same time, and stir to dissolve. Add 12g of lactic acid to 13g of ammonia water and mix evenly, then add the mixture dropwise into the flask, finally add 4g of glycerin, heat up to 60°C, and react for 2h to obtain a colorless liquid containing 3.57% zirconium.

Embodiment 3

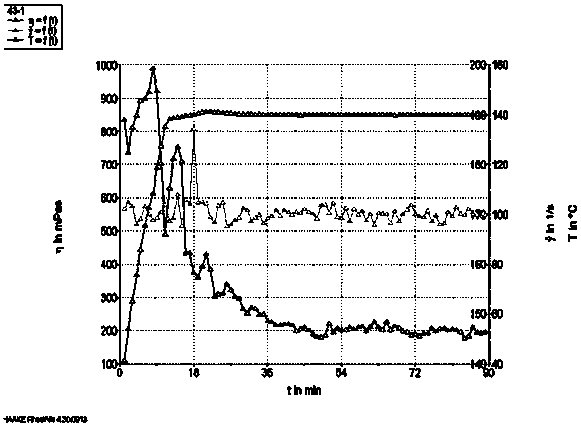

[0046] Example 3 Preparation of fracturing fluid base fluid

[0047] Add 494g water in mixer, add 2.25g carboxymethyl hydroxypropyl guar gum under stirring, after dissolving 3min, add 2.5g clay stabilizer tetramethylammonium chloride, 1.5g microemulsion drainage aid successively ( ME-1), 0.1g sodium hydroxide, 0.05g fungicide formaldehyde, stir and dissolve for 2min, let stand for 1h, and prepare a fracturing fluid base fluid with a concentration of carboxymethylhydroxypropyl guar gum of 0.45%. The apparent viscosity of fracturing fluid base fluid is 70mPa s (170s -1 ), the pH value is 10.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com