Preparation method of protein-modified phytosterol liposome powder

A phytosterol lipid and protein modification technology, which is applied in the field of preparation of protein-modified phytosterol liposome powder, can solve the problems of low solubility and reduced embedding rate, achieve good solubility, improve stability, and improve redispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

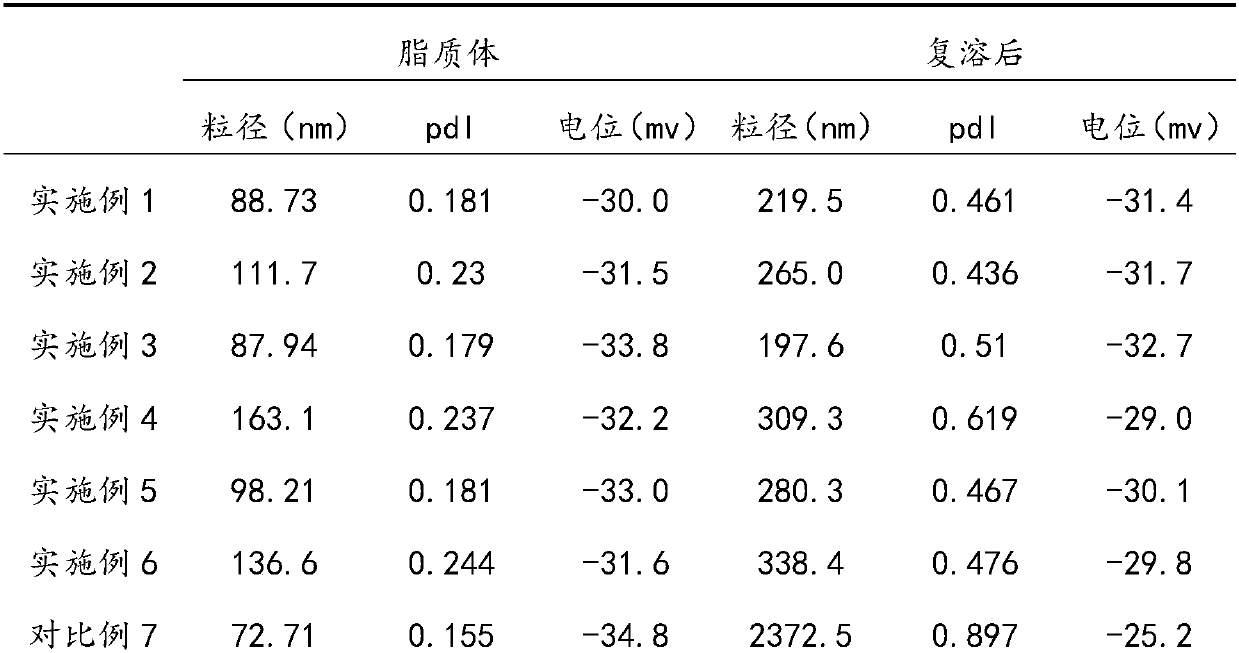

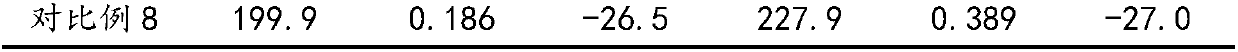

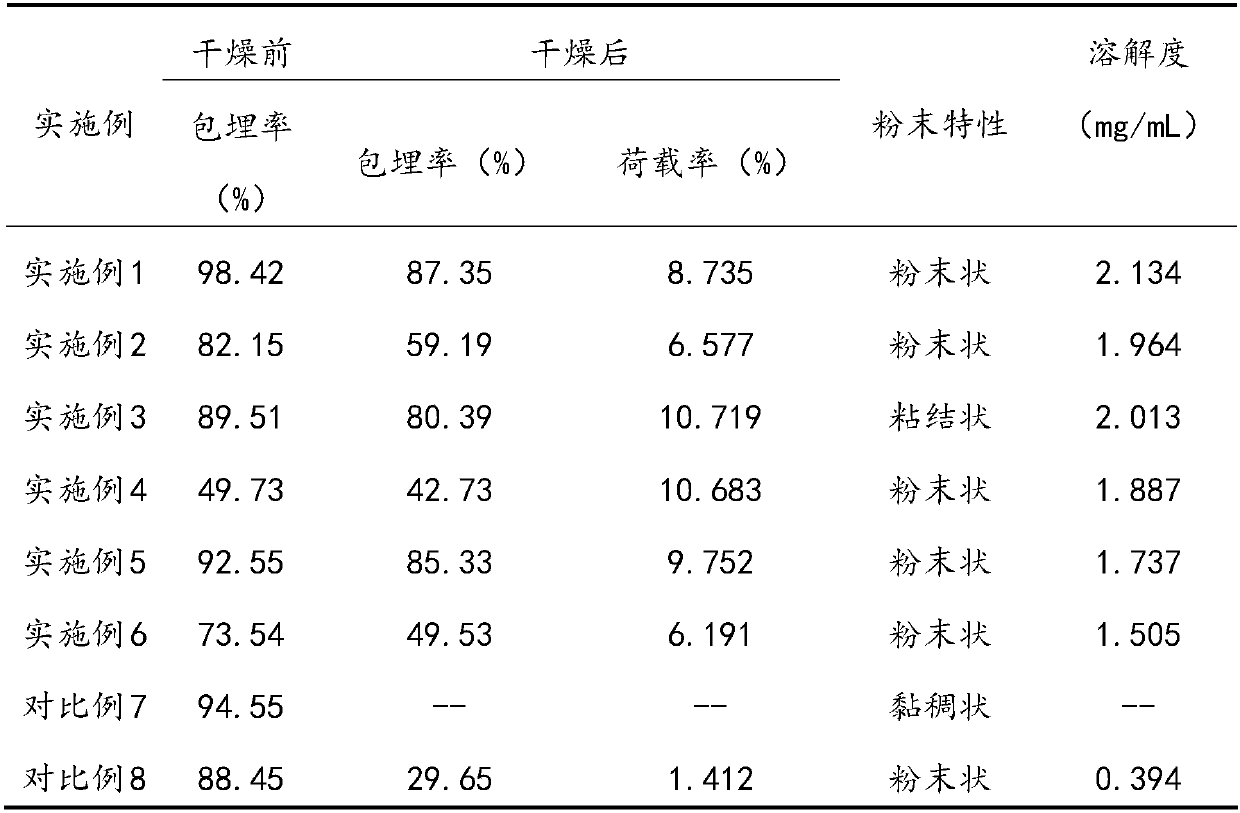

Examples

Embodiment 1

[0024] (1) Lecithin and phytosterol are added to absolute ethanol at a ratio of 4:1 (w / w), so that the concentration of phytosterol is 1% (w / v), and stirred at room temperature to dissolve;

[0025] (2) Add soybean protein isolate to deionized water at a ratio of 1% (w / v), stir and dissolve at room temperature, adjust pH to 7.0, and hydrate overnight at 4°C;

[0026] (3) Slowly inject the phytosterol-lecithin ethanol solution obtained in step (1) into the protein solution obtained in step (2) according to the volume ratio of 1:4, and disperse at a high speed of 10000r / min for 5min; then under 80MPa High-pressure homogenization 8 times to obtain protein-modified phytosterol liposomes;

[0027] (4) The phytosterol liposomes obtained in the step (3) were subjected to rotary evaporation at 40°C under a vacuum of 0.11 MPa to remove ethanol, and freeze-dried to obtain a freeze-dried powder.

Embodiment 2

[0029] (1) Lecithin and phytosterol are added to absolute ethanol at a ratio of 3:1 (w / w), so that the concentration of phytosterol is 2% (w / v), and stirred at room temperature to dissolve;

[0030] (2) Add soybean protein isolate to deionized water at a ratio of 1% (w / v), stir and dissolve at room temperature, adjust pH to 7.0, and hydrate overnight at 4°C;

[0031] (3) Slowly inject the phytosterol-lecithin ethanol solution obtained in step (1) into the protein solution obtained in step (2) according to the volume ratio of 1:4, and disperse at a high speed of 10000r / min for 3min; then under 90MPa High-pressure homogenization 4 times to obtain protein-modified phytosterol liposomes;

[0032] (4) The phytosterol liposomes obtained in the step (3) were subjected to rotary evaporation at 40°C under a vacuum of 0.13 MPa to remove ethanol, and freeze-dried to obtain a freeze-dried powder.

Embodiment 3

[0034] (1) Lecithin and phytosterol are added to absolute ethanol at a ratio of 4:1 (w / w), so that the concentration of phytosterol is 4% (w / v), and stirred at room temperature to dissolve;

[0035] (2) Add soybean protein isolate to deionized water at a ratio of 0.5% (w / v), stir and dissolve at room temperature, adjust pH to 7.0, and hydrate overnight at 4°C;

[0036] (3) Slowly inject the phytosterol-lecithin ethanol solution obtained in step (1) into the protein solution obtained in step (2) according to the volume ratio of 1:4, and disperse at a high speed of 8000r / min for 5min; then under 80MPa High-pressure homogenization 4 times to obtain protein-modified phytosterol liposomes;

[0037] (4) The phytosterol liposomes obtained in the step (3) were subjected to rotary evaporation at 45° C. to remove ethanol under a vacuum of 0.11 MPa, and freeze-dried to obtain freeze-dried powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com