Water quality improver and preparation method thereof

A technology of water quality improver and thickener, applied in chemical instruments and methods, water/sewage treatment, animal husbandry wastewater treatment, etc., can solve the problems of increasing the oxygen consumption of the substrate, deteriorating water quality, affecting the survival of farmed animals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

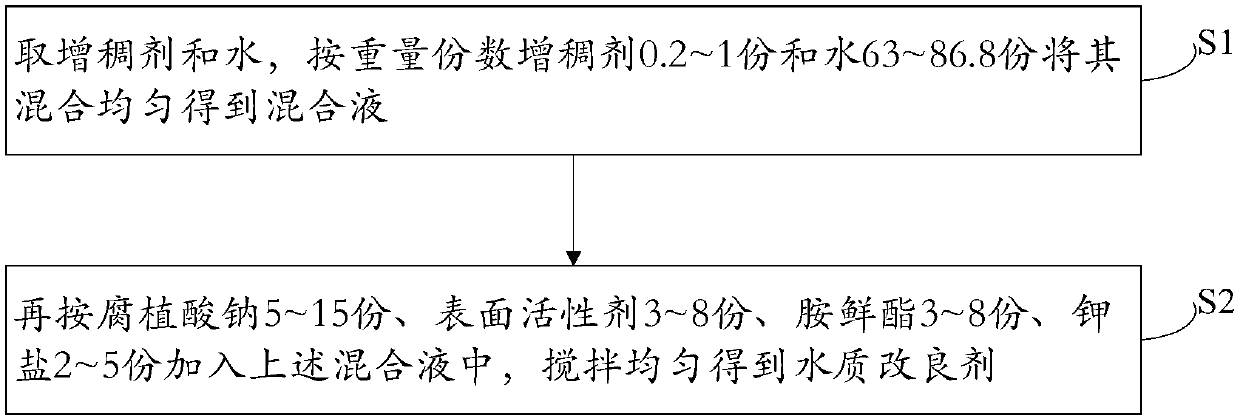

[0028] The present invention also provides a preparation method of the above-mentioned water quality improver, comprising the following steps:

[0029] Step S1: Take the thickener and water, and mix them uniformly to obtain a mixed liquid by weight parts of 0.2-1 part of the thickener and 63-86.8 parts of water. 0.2-1 part by weight of the thickener and 63-86.8 parts by weight of water are added into the batching tank and stirred evenly.

[0030] In the batching tank, use a mixer with a rotation speed of 40-60 revolutions per minute to stir for 20-40 minutes to stir the thickener and water evenly to obtain a mixed solution, and the thickener and water are stirred within the temperature range of 30°C to 50°C , preferably 40°C. The thickener is selected from one or more of sodium carboxymethylcellulose, sodium carboxyethylcellulose, xanthan gum, and polyacrylamide, and the parts by weight are preferably 0.5-1 part.

[0031] Step S2: Add 5-15 parts of sodium humate, 3-8 parts o...

Embodiment 1

[0038] The water quality improver of the present embodiment comprises the following components by weight:

[0039] Mix 10 parts of sodium humate, 0.5 parts of sodium carboxymethylcellulose, 3 parts of potassium chloride, 4 parts of sodium dodecylbenzenesulfonate, 5 parts of diethyl ethyl ethyl ethylate and 77.5 parts of water to obtain a water quality improver.

[0040] The preparation method of the water quality improver of the present embodiment is as follows: add 0.5 parts of sodium carboxymethylcellulose and 77.5 parts of water into the batching tank and stir for 30 minutes with a mixer whose rotation speed is 40 revolutions per minute until the mixed solution is obtained evenly, and then add Add 10 parts of sodium humate, 3 parts of potassium chloride, 4 parts of sodium dodecylbenzene sulfonate, and 5 parts of diethyl ethyl to the above mixture, and stir for 30 minutes at room temperature with a mixer at a speed of 50 rpm Until the water quality improver is obtained evenl...

Embodiment 2

[0042] The water quality improver of the present embodiment comprises the following components by weight:

[0043] Mix 5 parts of sodium humate, 1 part of sodium carboxyethyl cellulose, 2 parts of potassium chloride, 3 parts of potassium sulfate, 8 parts of calcium dodecylbenzenesulfonate, 3 parts of diethyl diethylethyl cellulose and 78 parts of water to obtain water quality Improver.

[0044] The preparation method of the water quality improver of this embodiment is: add 1 part of carboxyethyl cellulose sodium and 78 parts of water into the batching tank and stir for 40 minutes with a mixer with a rotation speed of 40 rpm until the mixed solution is obtained evenly, and then add Add 5 parts of sodium humate, 2 parts of potassium chloride, 3 parts of potassium sulfate, 8 parts of calcium dodecylbenzenesulfonate, and 3 parts of diethyl hexanoate into the above mixture, and use a speed of 40 rpm at room temperature The blender stirred for 35 minutes until the water quality imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com