A method and equipment for clean and environmentally friendly production of 1,1',2,3-tetrachloropropene

A tetrachloropropene, clean and environmentally friendly technology, applied in the chemical industry, can solve the problems of complex procedures and difficult large-scale production, and achieve the effects of simple process flow, cost saving, and simple solid waste treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

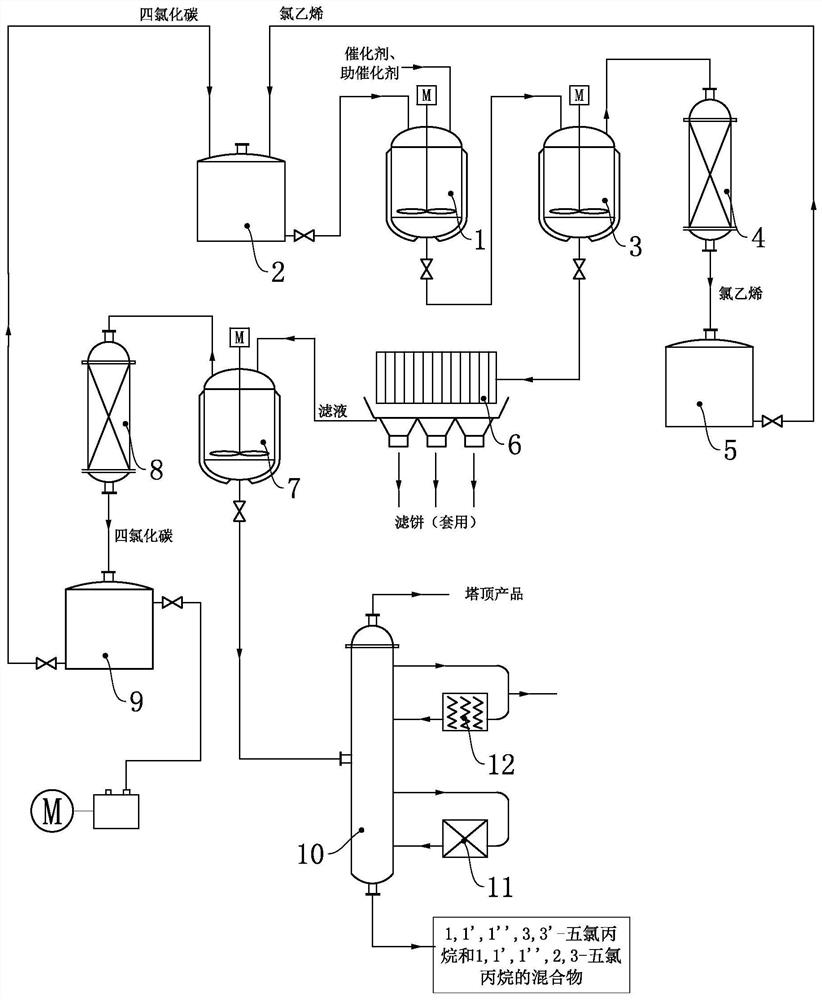

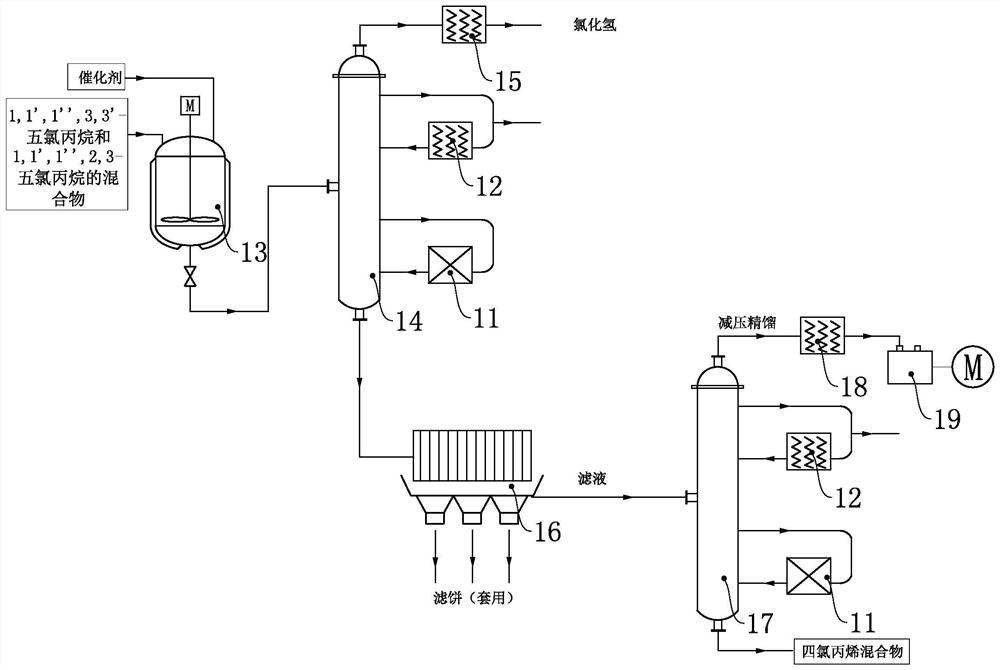

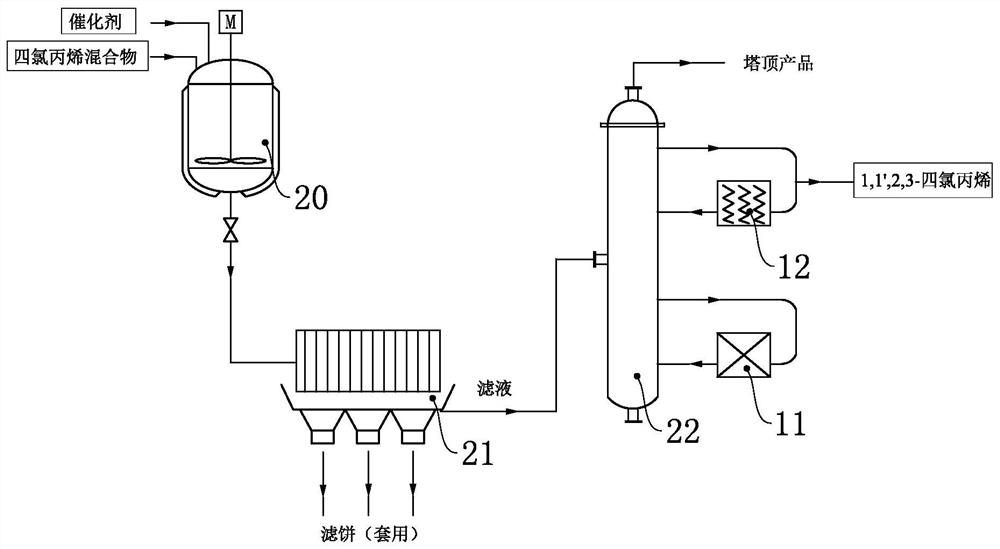

[0058] A method for clean and environment-friendly production of 1,1',2,3-tetrachloropropene, comprising the steps of:

[0059] S1. Use nitrogen to replace the air in the No. 1 high-pressure reactor. The pressure in the No. 1 high-pressure reactor is controlled at 0.3 MPa each time, and the operation is repeated three times; The pressure in the reactor is 0.2MPa;

[0060] S2, carbon tetrachloride is added in the No. 1 autoclave of step S1, then add catalyst, cocatalyst, wherein, catalyst adopts Fe / FeCl 3 For the catalyst system, the co-catalyst is phosphoric acid ester, preferably phosphoric acid methacrylate. In addition, the weight ratio of the catalyst to the co-catalyst is 3:1. Close the lid of the autoclave tightly, feed nitrogen gas until the internal pressure of the No. 1 autoclave is 0.3MPa, and let the autoclave stand for 30 minutes to ensure that the No. 1 autoclave does not leak. ; After making the electric heating jacket of No. 1 autoclave be warming up to 65 ℃, ...

Embodiment 2

[0069] A method for clean and environment-friendly production of 1,1',2,3-tetrachloropropene, comprising the steps of:

[0070] S1. Use nitrogen to replace the air in the No. 1 high-pressure reactor. The pressure in the No. 1 high-pressure reactor is controlled at 0.5 MPa each time, and the operation is repeated three times; The pressure in the reactor is 0.4MPa;

[0071] S2, carbon tetrachloride is added in the No. 1 autoclave of step S1, then add catalyst, cocatalyst, wherein, catalyst adopts Fe / FeCl 3 For the catalyst system, the co-catalyst is phosphoric acid ester, preferably phosphoric acid methacrylate. In addition, the weight ratio of the catalyst to the co-catalyst is 5:1. Close the lid of the autoclave tightly, feed nitrogen gas until the internal pressure of the No. 1 autoclave is 0.5 MPa, and let the autoclave stand for 30 minutes to ensure that the No. 1 autoclave does not leak. ; After making the electric heating jacket of No. 1 autoclave be warming up to 80 ℃,...

Embodiment 3

[0080] A method for clean and environment-friendly production of 1,1',2,3-tetrachloropropene, comprising the steps of:

[0081] S1. Use nitrogen to replace the air in the No. 1 high-pressure reactor. The pressure in the No. 1 high-pressure reactor is controlled at 0.4MPa each time, and the operation is repeated three times; The pressure in the reactor is 0.3MPa;

[0082] S2, carbon tetrachloride is added in the No. 1 autoclave of step S1, then add catalyst, cocatalyst, wherein, catalyst adopts Fe / FeCl 3 For the catalyst system, the co-catalyst is phosphoric acid ester, preferably phosphoric acid methacrylate. In addition, the weight ratio of the catalyst to the co-catalyst is 4:1. Close the lid of the autoclave tightly, feed nitrogen gas until the internal pressure of the No. 1 autoclave is 0.4MPa, and let the autoclave stand for 30 minutes to ensure that the No. 1 autoclave does not leak. ; After the electric heating jacket of No. 1 autoclave is warmed up to 75 ℃, pass into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com