Automotive coating based on organic fluorine unsaturated polyester resin emulsion and preparation method of automotive coating

A polyester resin, unsaturated technology, applied in the direction of polyester coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor hydrophobicity, poor corrosion resistance, high baking temperature, etc., to achieve not easy to crack, strong corrosion resistance, Excellent anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

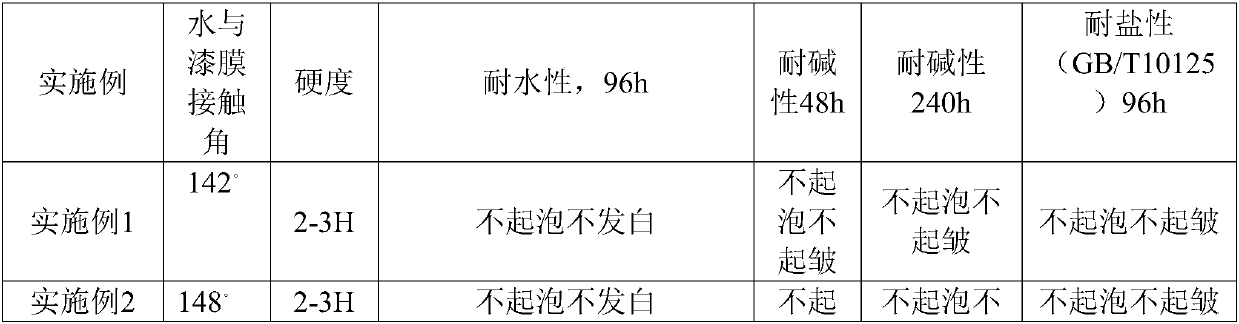

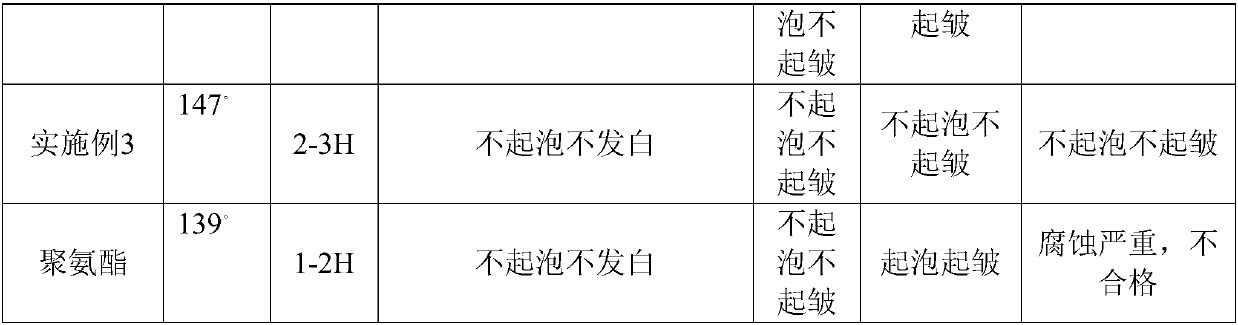

Embodiment 1

[0024] A method for preparing an organic fluorine type unsaturated polyester resin emulsion X, characterized in that, in parts by weight, comprising the following steps:

[0025] (1) 20 parts of undecafluorotrimethylolpropane, 5 parts of decafluoroneopentyl glycol, 5 parts of octafluorobutanediol, 10 parts of tetrafluorophthalic anhydride, 25 parts of difluoromaleic anhydride 1. Put 5 parts of xylene into the reaction device, heat to 160°C for 6 hours under stirring; Continue to react at 180°C for 3 hours until the acid value is 55±5mgKOH / g, and then remove the solvent by distillation under reduced pressure to obtain a hydrophilic organic fluorine type unsaturated polyester resin;

[0026] (2) Emulsification: cool down the hydrophilic organic fluorine type unsaturated polyester resin to 60°C, add 5 parts of triethylamine for neutralization reaction, and then add 0.4 parts of allyl sulfoalkoxy succinic acid The diester sodium salt and 150 parts of deionized water were disperse...

Embodiment 2

[0028] A method for preparing an organic fluorine-type unsaturated polyester resin emulsion Y, characterized in that, in parts by weight, comprising the steps of:

[0029] (1) 10 parts of undecafluorotrimethylolpropane, 10 parts of decafluoroneopentyl glycol, 10 parts of octafluorobutanediol, 20 parts of tetrafluorophthalic anhydride, 15 parts of difluoromaleic anhydride 10 parts of xylene were put into the reaction device, and heated to 120°C for 8 hours under stirring; then the temperature was raised to 160°C, and 15 parts of polytetramethylene ether glycol was added to the reaction device to continue the reaction for 4 hours, at a temperature of 120°C Continue to react for 5h until the acid value is 45±5mgKOH / g, and remove the solvent by distillation under reduced pressure to obtain a hydrophilic organic fluorine type unsaturated polyester resin;

[0030] (2) Emulsification: cool down the hydrophilic organic fluorine type unsaturated polyester resin to 30°C, add 10 parts of...

Embodiment 3

[0032] A method for preparing an organic fluorine-type unsaturated polyester resin emulsion Z, characterized in that, in parts by weight, comprising the steps of:

[0033] (1) 13 parts of undecafluorotrimethylolpropane, 7 parts of decafluoroneopentyl glycol, 9 parts of octafluorobutanediol, 18 parts of tetrafluorophthalic anhydride, 21 parts of difluoromaleic anhydride , Put 6 parts of xylene into the reaction device, heat to 140°C for 6.5 hours under stirring; then raise the temperature to 175°C, add 11 parts of polytetrahydrofuran ether glycol into the reaction device to continue the reaction for 3 hours, and continue the reaction at a temperature of 140°C 3-5h until the acid value is 47±5mgKOH / g, and the solvent is removed by distillation under reduced pressure to obtain a hydrophilic organic fluorine type unsaturated polyester resin;

[0034] (2) Emulsification: cool down the hydrophilic organic fluorine type unsaturated polyester resin to the inverse emulsification transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com