Preparation method of anion-exchange membrane with poly(sulfonated dopamine) layer

A technology of polysulfonated dopamine layer and anion exchange membrane, which is applied in the direction of anion exchanger materials, chemical instruments and methods, membranes, etc., can solve the problems of cumbersome methods, easily polluted, low selective separation performance, etc., and achieves a simple process. , reducing the reaction steps, the effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 self-polymerization deposition, the step of modified anion exchange membrane

[0037] A kind of preparation method of the anion exchange membrane of band polysulfonated dopamine layer of the present invention, comprises the steps:

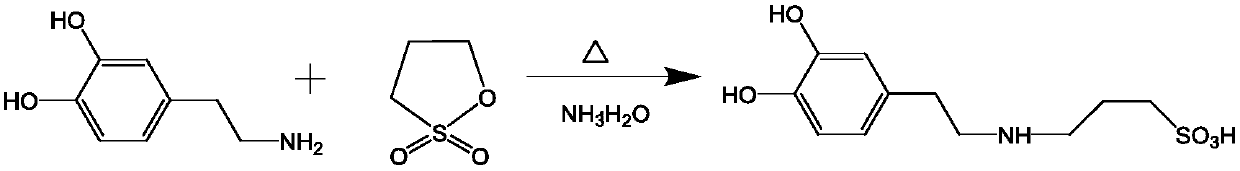

[0038] Use the homogeneous Japanese FUJIFILM commercialized anion exchange membrane as the base membrane, rinse the original commercial membrane with 0.2M NaOH and 0.2M HCl solution in sequence, wash away the impurities on the membrane surface and the protective substances attached to the surface of the commercial membrane, and store the membrane in 0.5M NaCl solution 24 hours. The synthetic steps and structural formula of the sulfonated dopamine of self-polymerization deposition are as follows: figure 1 shown. 1.1376g (6mmol) of dopamine hydrochloride was dissolved in 150mL of absolute ethanol and placed in a 250mL flask, slowly added 416 μL (3mmol) of 28wt% ammonia and 799mg (6.5mmol) of 1,3-propane sultone, After reacting ...

Embodiment 2

[0040] Embodiment 2 carries out selectivity test for autopolymerization deposition, modified anion exchange membrane

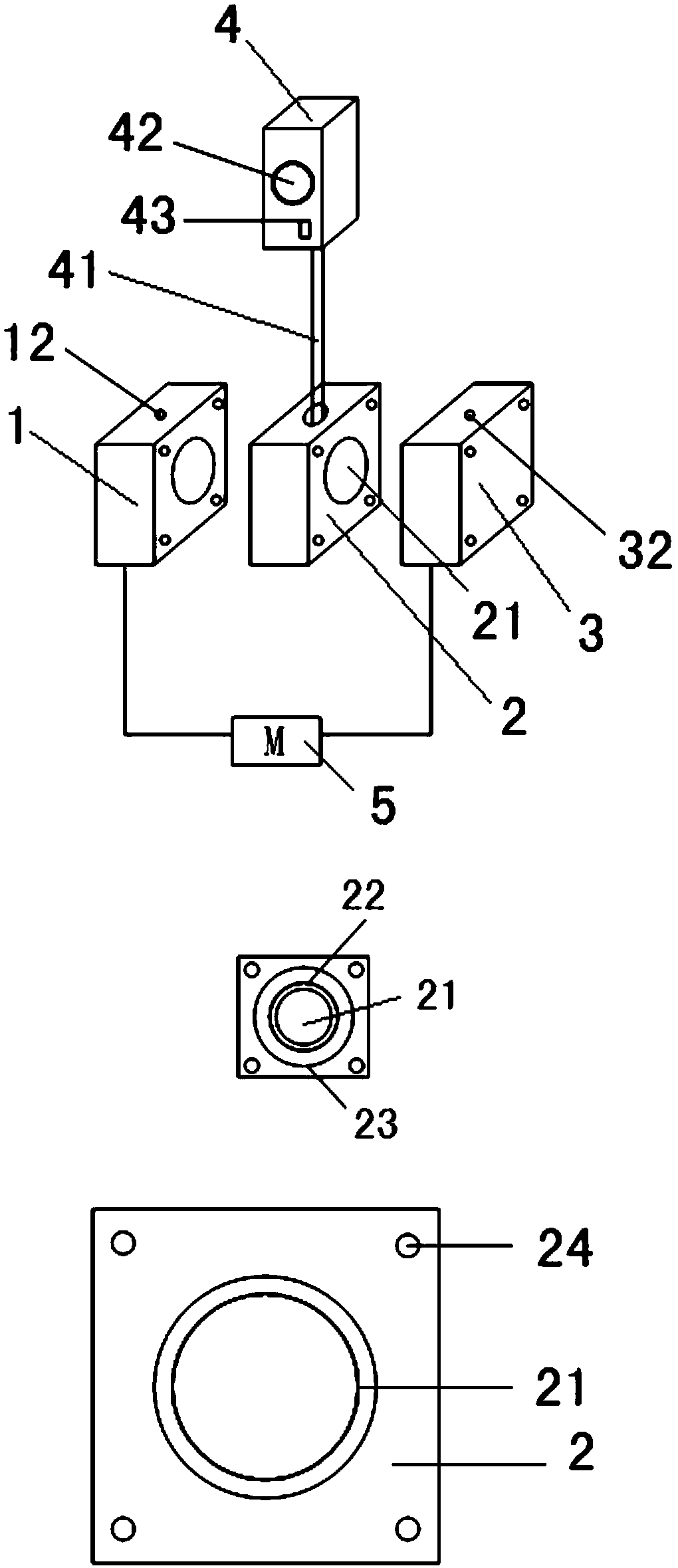

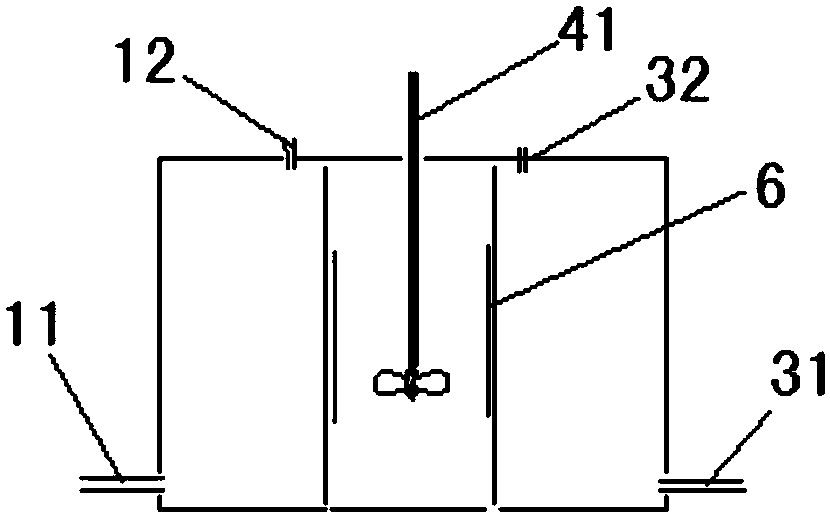

[0041] Taking the modified membranes prepared in Example 1 for different self-polymerization deposition times as an example, the membranes were placed in an electrodialysis device for testing. The schematic diagram of the selectivity test of the membrane is shown in image 3 shown. Each chamber has a volume of 100mL and an effective area of 19.625cm 2 . The two middle chambers are the dilute chamber and the concentrated chamber, in which 100mL of 0.05M Na 2 SO 4 Mix the solution with NaCl, add 0.2M Na to the two electrode chambers next to it 2 SO 4 solution as electrolyte. At 5.1mA·cm -2 Operate under the current density, the electrodialysis time is controlled as 120min, and every 30min, the side feed liquid of the dilute chamber is taken to measure its Cl by ion chromatography. - and SO 4 2- concentration. Selective size is given by Indicates ...

Embodiment 3

[0046] Embodiment 3 carries out selective stability test for autopolymerization deposition, modified anion exchange membrane

[0047] Taking the modified membrane with a self-polymerization deposition time of 48 hours prepared in Example 1 as an example, the membrane was placed in an electrodialysis device for testing, and the membrane to be tested was stored in 0.5M NaCl solution for one month before testing. The test schematic is as image 3 shown. Each chamber has a volume of 100mL and an effective area of 19.625cm 2 . The two middle chambers are the dilute chamber and the concentrated chamber, in which 100mL of 0.05M Na 2 SO 4 Mix the solution with NaCl, add 0.2M Na to the two electrode chambers next to it 2 SO 4 solution as electrolyte. At 5.1mA·cm -2 Run under the current density, the test time is 80 hours in total, every 2 hours, take the side feed liquid of the dilute chamber and measure Cl by ion chromatography - and SO 4 2- concentration. The feed solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com