Application of a Copper Metal Organic Framework Membrane in Catalytic Degradation of Organic Dyes

An organic framework, catalytic degradation technology, applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, water pollutants, etc., to achieve no energy consumption, high catalytic performance, simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

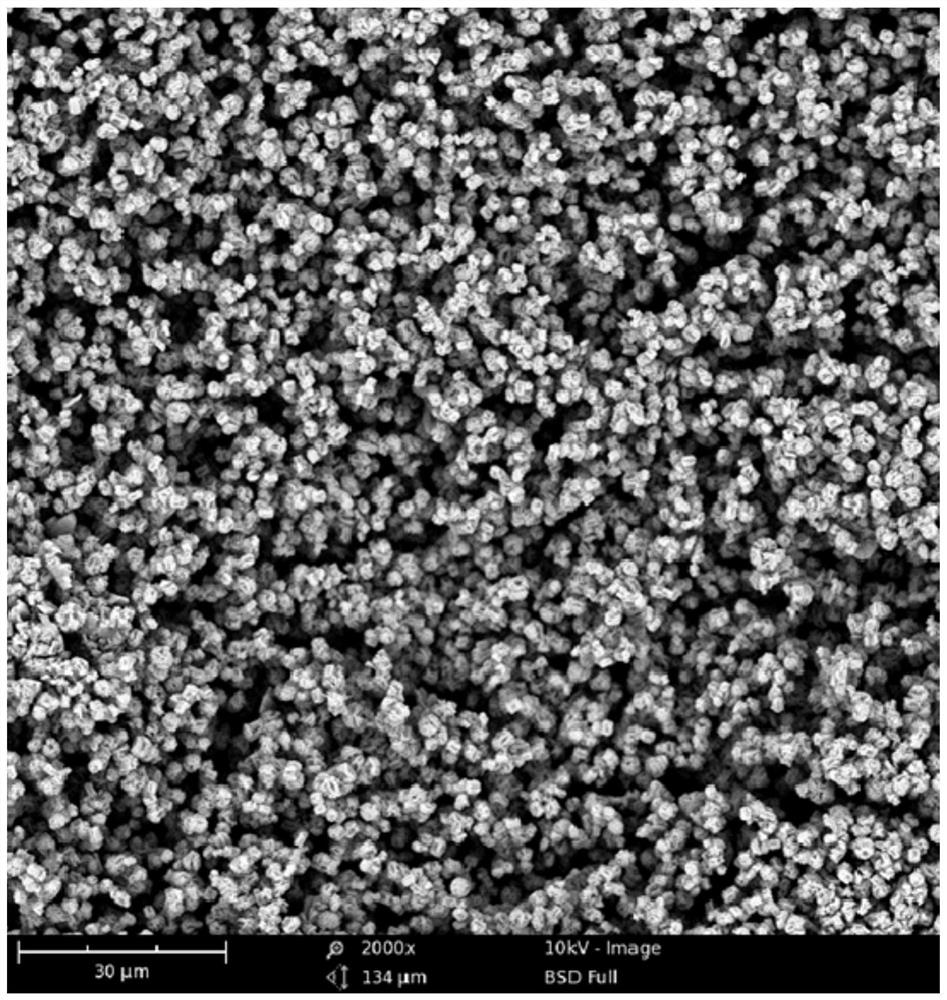

[0021] At room temperature, 2mmol Cu(NO 3 ) 2 ·3H 2 Dissolve O in 40mL DMF, stir until it is completely dissolved, then add 2mmol bpd to the solution, stir well, let the solution stand for 10min and then filter, put the obtained filtrate A in a sealable container jar middle. Select 20×10mm Al 2 o 3 , put it in anhydrous ethanol and ultrasonically clean it for 10 minutes, then dry it at 50°C and soak it in the above-mentioned sealable container jar. Take a 10ml glass test tube, fill it with 8ml ether, put it into a jar upright, and seal the jar well. About 7 days, Cu(II) metal-organic framework film can be obtained, the electron microscope picture is as follows figure 1 , The crystal particles are uniform spherical, and the particle diameter is about 2 μm.

Embodiment 2

[0023] The operation steps of Example 1 were repeated, except that the carrier was a graphite sheet of 20×10 mm. The results showed that the crystals constituting the metal-organic framework membrane were still spherical, but the diameter of the particles changed to about 1 μm.

Embodiment 3

[0025] Repeat the operation steps of Example 1, except that the carrier is a 20×10mm copper mesh. As a result, compared with Example 1, most of the crystals that make up the metal-organic framework membrane are spherical particles, and some fine blocks appear in it. shaped particles with a particle size of about 1 μm.

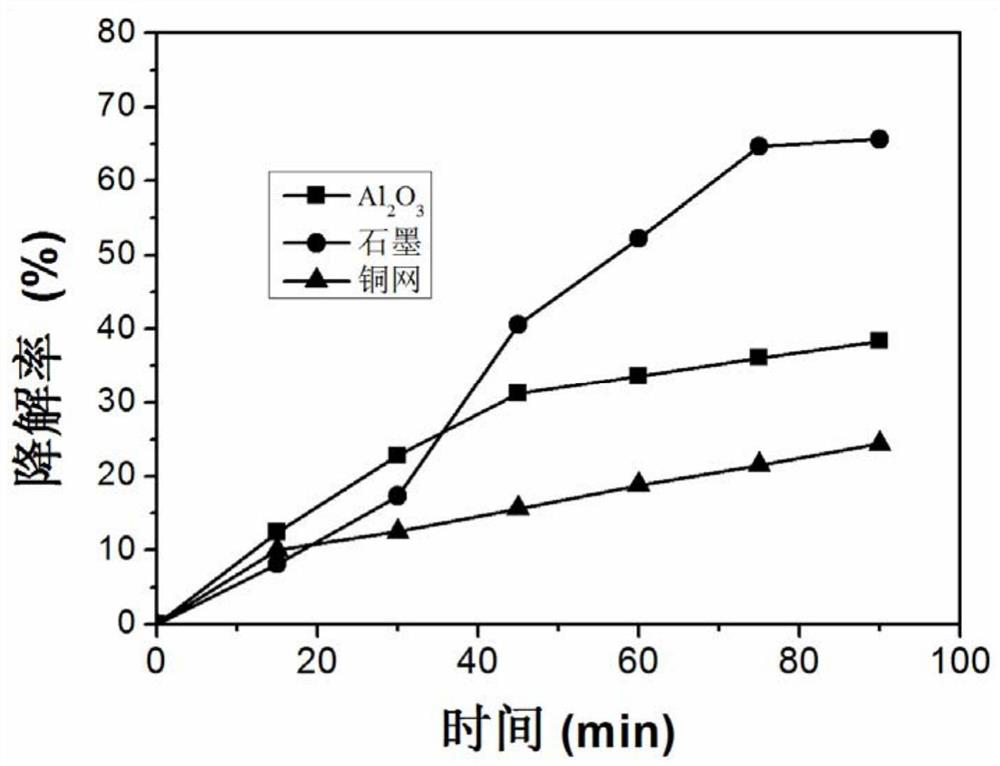

[0026] figure 1 It is the SEM picture of the sample obtained in Example 1. The spherical crystals form a dense film on the carrier, and the MOFs crystal particle size is about 1 μm. figure 2 The curves of sample catalytic degradation of organic dye methyl orange were prepared for Examples 1-3. The initial volume of the methyl orange solution was 125mL, and the concentration was 12ppm. At room temperature, a metal-organic framework membrane with an area of 20×10mm was taken and fixed in the methyl orange solution. It can be seen from the figure that the catalytic effect of MOFs crystal film is the best when graphite sheet is used as the carrier among the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com