High-power concentration distillation desalting system and method based on induced crystallization method

A technology for inducing crystallization and distillation desalination, which is applied in the field of high-concentration distillation and desalination systems and seawater desalination, can solve the problems of high operating cost, large consumption of chemicals, and increased system operating cost, and achieves reduction of system operation power consumption and consumption cost. , the effect of eliminating additional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

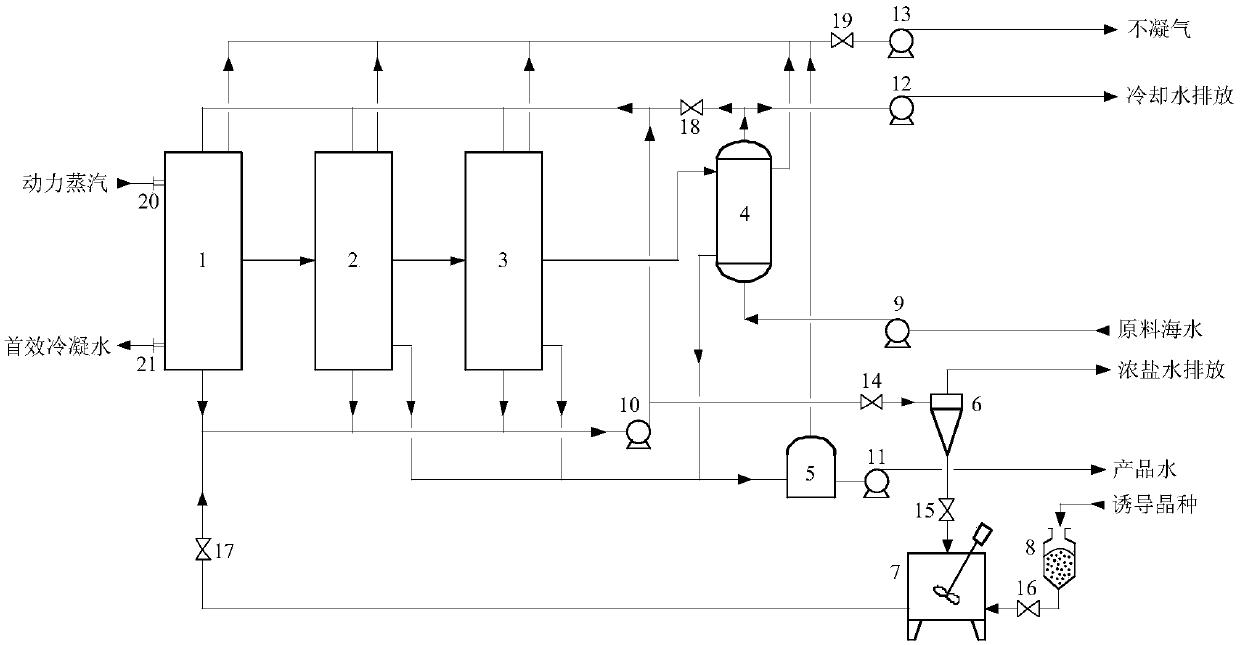

[0037] A high power concentration distillation and desalination method based on the induced crystallization method, comprising the steps of:

[0038] 1) Use the above-mentioned high-power concentrated distillation and desalination system based on the induced crystallization method, in which 3 evaporators are taken as an example;

[0039] 2) Turn on the raw material seawater feed pump 9, feed valve 18, forced circulation pump 10, concentrated brine discharge valve 14, drain valve 15, cooling water discharge pump 12, vacuum pump 13 and non-condensable gas control valve 19, and pass power steam The inlet 20 feeds power steam into the first effect evaporator 1;

[0040]3) Open the seed crystal control valve 16, pass the induced crystal seeds in the seed crystal tank 8 into the mother liquor tank 7, and the mother liquor tank 7 has a stirring device, so that the induced crystal seeds in the tank can always be in a suspended state;

[0041] 4) The raw seawater is sent to the conden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com