Lasting corrosion-resistant water-based acrylic resin and preparation method thereof

A water-based acrylic and anti-corrosion technology, which is applied in the preparation of carboxylic acid halides, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve environmental pollution, endanger the health of front-line workers in production and construction, ecosystem and human health threats etc. to achieve the effects of low surface tension, long-lasting antibacterial and anti-corrosion properties, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

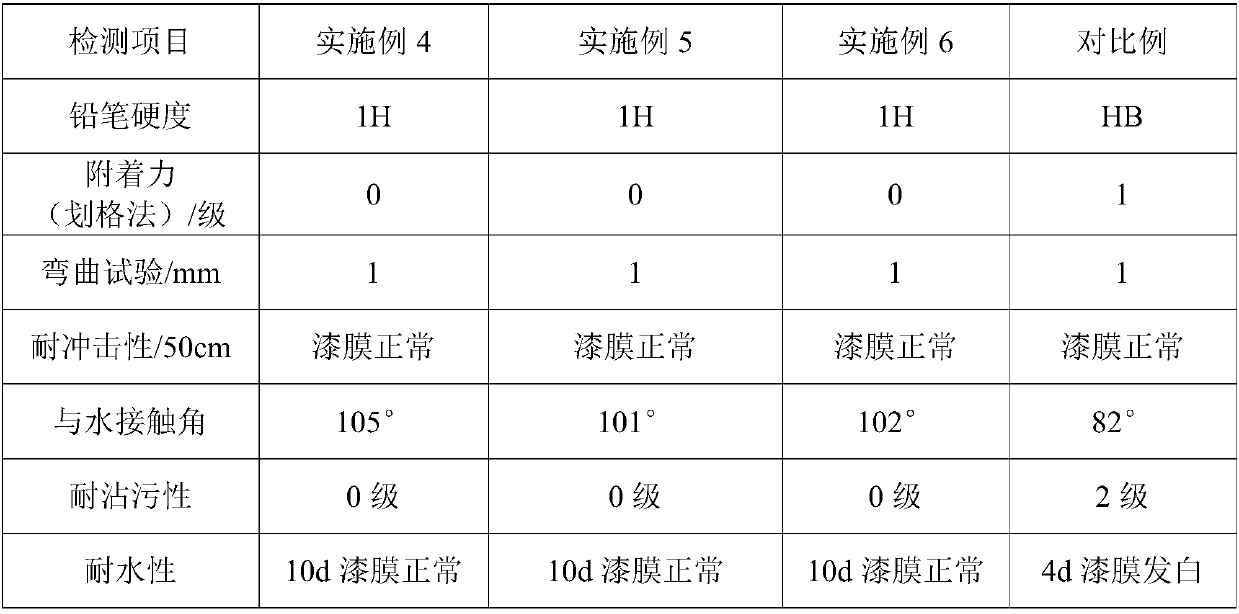

Examples

Embodiment 1

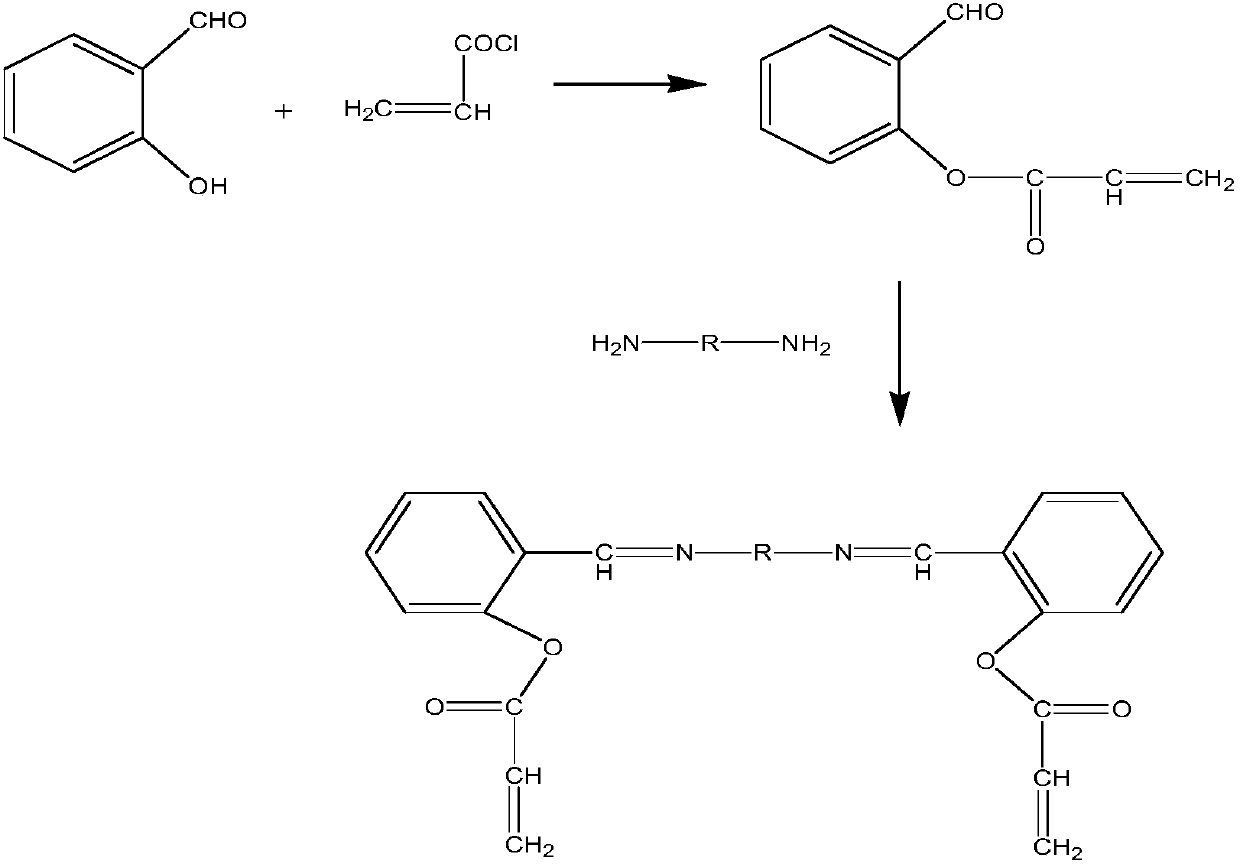

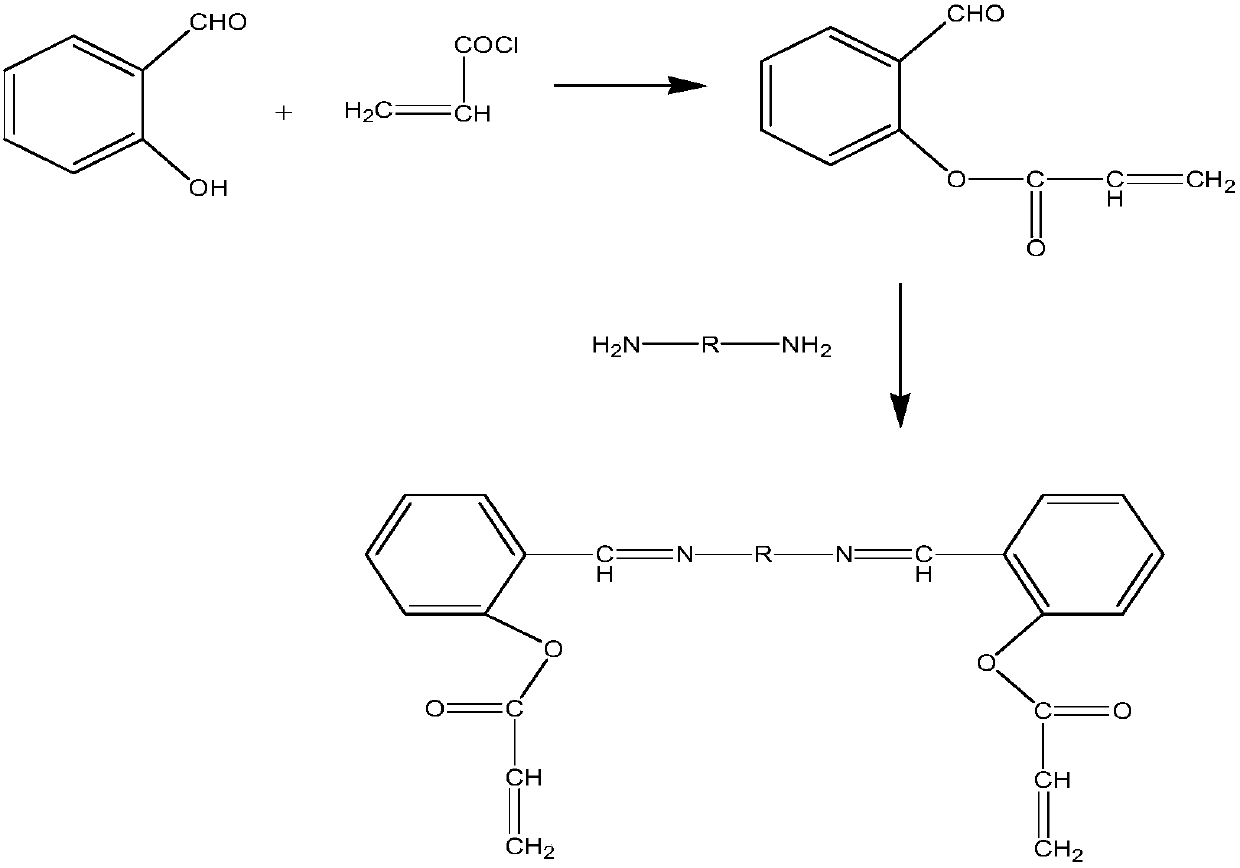

[0032] A kind of diaromatic Schiff base acrylic acid A, its preparation steps are as follows:

[0033] a) Weigh 28.0 parts of salicylaldehyde and 15.8 parts of potassium carbonate in the reaction kettle in sequence, add 6.0 parts of N,N-dimethylformamide, stir and dissolve evenly, react at 80°C for 1 hour, and then add 20.6 parts of acryloyl chloride and 0.06 parts of potassium iodide, continue to react for 5 hours, cool after stopping the reaction, filter with suction, wash with water until neutral, and dry to obtain the reactant intermediate I;

[0034] b) In a reaction kettle equipped with a thermometer, agitator, and condenser tube, add the reactant intermediate I and 10.0 parts of ethanol, raise the temperature to 80°C and stir to dissolve evenly, slowly add 12.4 parts of phenylenediamine and 6.34 parts of ethanol solution dropwise After the dropwise addition, 0.8 parts of glacial acetic acid was added, and the reflux reaction was continued for 5 hours. After the reaction...

Embodiment 2

[0036] A kind of diaromatic Schiff base acrylic acid B, its preparation steps are as follows:

[0037] a) Weigh 26.0 parts of salicylaldehyde and 14.7 parts of potassium carbonate in the reaction kettle in sequence, add 5.0 parts of N,N-dimethylformamide, stir and dissolve evenly, react at 80°C for 1 hour, and then add 19.2 parts of acryloyl chloride and 0.05 parts of potassium iodide, continue to react for 5 hours, cool after stopping the reaction, filter with suction, wash with water until neutral, and dry to obtain the reactant intermediate II;

[0038] b) Add 15.0 parts of reactant intermediate II and ethanol to a reaction kettle equipped with a thermometer, agitator and condenser tube, raise the temperature to 80°C, stir and dissolve evenly, slowly add 6.4 parts of ethylenediamine and 12.95 parts of ethanol solution dropwise After the dropwise addition, add 0.7 parts of glacial acetic acid, continue to reflux for 5 hours, cool to room temperature after the reaction is com...

Embodiment 3

[0040]A kind of diaromatic Schiff base acrylic acid C, its preparation steps are as follows:

[0041] a) Weigh 30.0 parts of salicylaldehyde and 16.9 parts of potassium carbonate in the reaction kettle in sequence, add 7.5 parts of N,N-dimethylformamide, stir and dissolve evenly, react at 80°C for 1 hour, and then add 22.2 parts of acryloyl chloride and 0.08 parts of potassium iodide, continue to react for 5 hours, cool after stopping the reaction, filter with suction, wash with water until neutral, and dry to obtain the reaction product intermediate III;

[0042] b) In a reaction kettle equipped with a thermometer, a stirrer, and a condenser, add the reactant intermediate III and 10.0 parts of ethanol, heat up to 80°C and stir to dissolve evenly, slowly add 7.4 parts of 1,6-hexamethylenediamine and 5.1 parts of ethanol solution, after the dropwise addition, add 0.82 parts of glacial acetic acid, and continue the reflux reaction for 6 hours. After the reaction is complete, coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com