Super-weather-resistant low-VOC bus paint and preparation method thereof

A super-weather-resistant and bus-resistant technology, which is applied to biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve the problems of high material costs, equipment investment and energy consumption, and water resistance of only 10 days. , to achieve the effect of simple preparation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

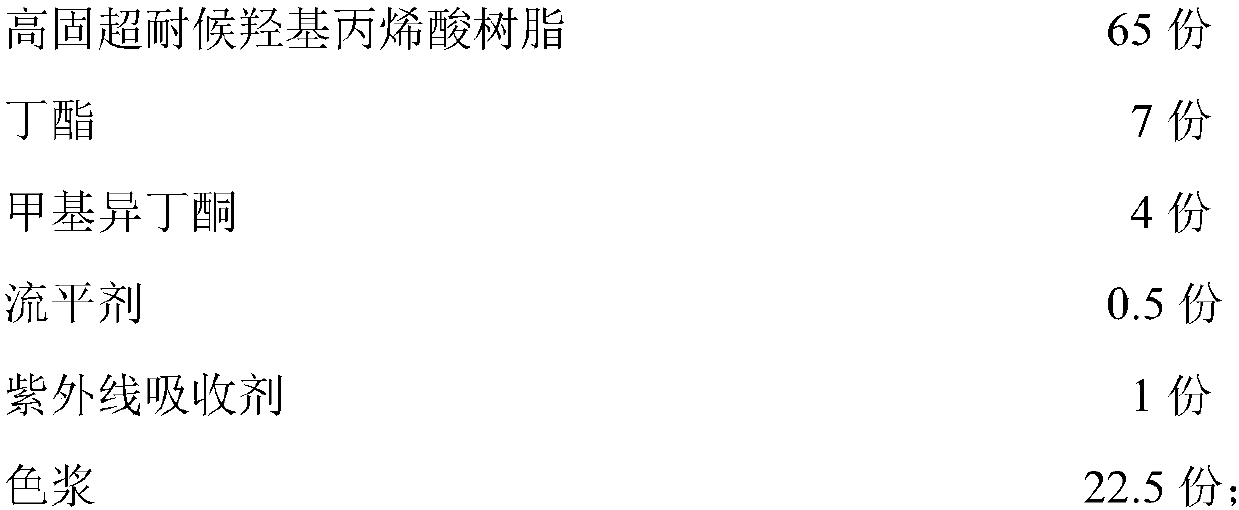

Embodiment 1

[0045] Preparation of super weather-resistant low-VOC bus color paint

[0046] The formula of super weather-resistant low-VOC bus color paint is shown in Table 1, and its preparation process is as follows:

[0047] (1) drop into the container successively low-molecular-weight high-solid super-weather-resistant hydroxyacrylic resin, butyl ester and MIBK, and stir for 5-10 minutes at a speed of 300-600 rpm, so that the materials are evenly mixed;

[0048](2) Add color paste to the mixture obtained in step (1), and stir at the same stirring rate and time as step (1), to obtain component A;

[0049] (3) Add low-molecular polyisocyanate curing agent, butyl ester and PMA into the container, and mix evenly to obtain component B, wherein the mixing and stirring speed is 300-600 rpm, and the stirring time is 5-10 Minutes, to obtain component B;

[0050] (4) Mix according to the mass ratio of A and B at 2:1 to obtain a super weather-resistant low-VOC bus color paint.

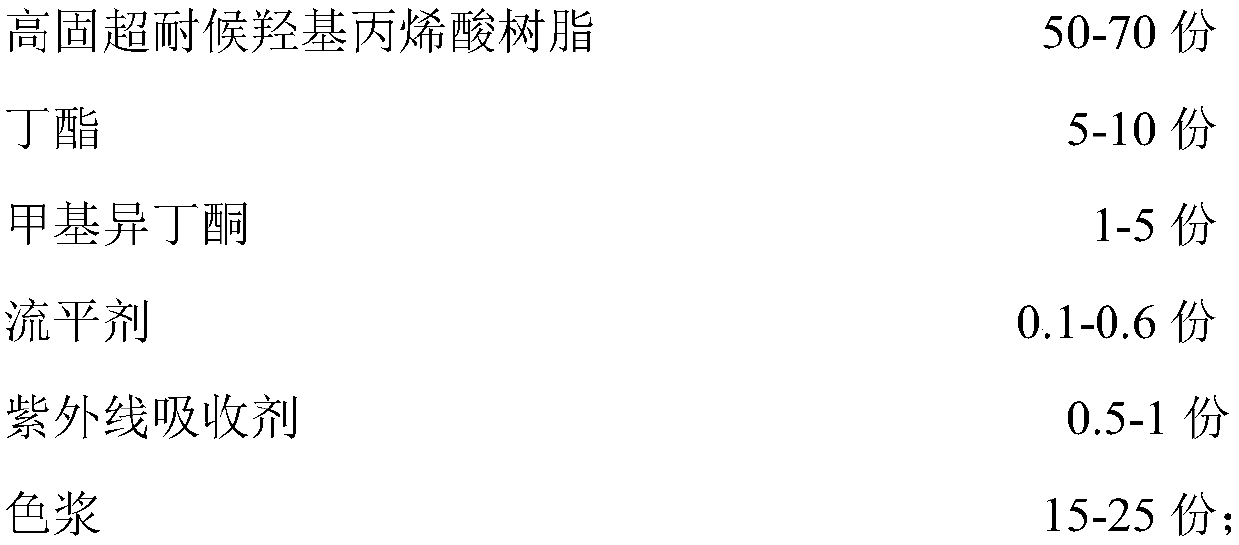

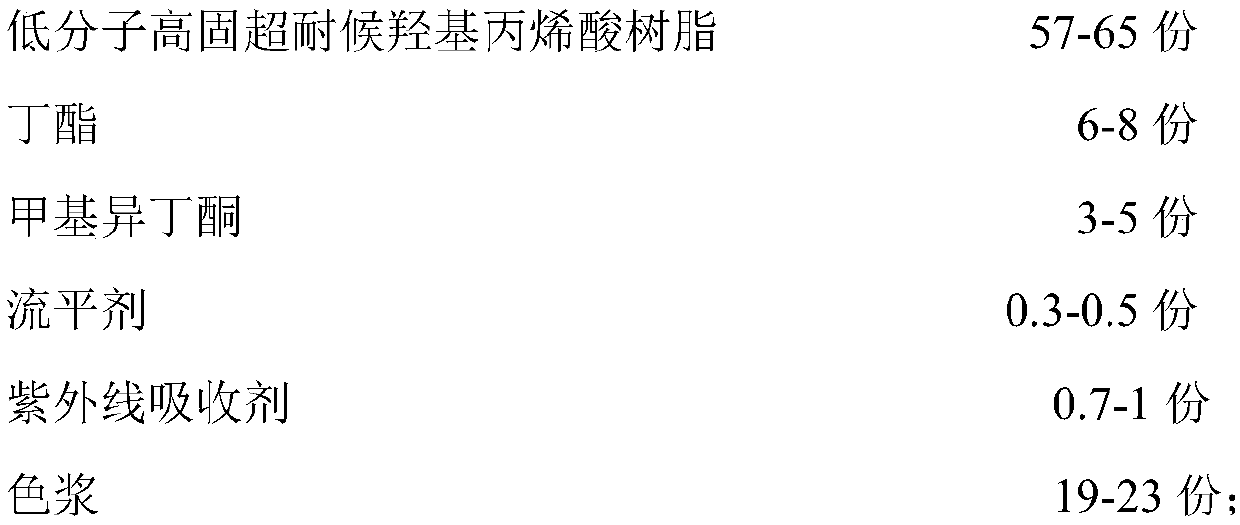

[0051] Table 1...

Embodiment 2

[0058] Table 3 shows the feeding formula for changing the content of each substance while ensuring that the types of substances in the formula are unchanged in Example 2, and preparing the bus color paint according to the preparation process of Example 1.

[0059] The performance of the bus color paint prepared by formula 6-9 is shown in Table 4, and compared with the performance of Table 2, it can be seen that when the weight parts of each material type of A and B components exceed the scope disclosed in Table 1 in Example 1, the obtained The performance of various aspects of the color paint of the bus is drastically reduced.

[0060] Table 3 different formulations of bus color paint

[0061]

[0062]

[0063] The performance detection data of the bus color paint that table 4 formula 6-9 obtains

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

| gloss loss | aaaaa | aaaaa |

| gloss loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com