Carbonized heating supply system for rod production from forestry waste

A technology for forestry waste and heating system, applied in the field of forestry waste treatment, can solve the problems of serious smoke pollution and low combustion efficiency, and achieve the effects of long combustion time, reduced energy consumption and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

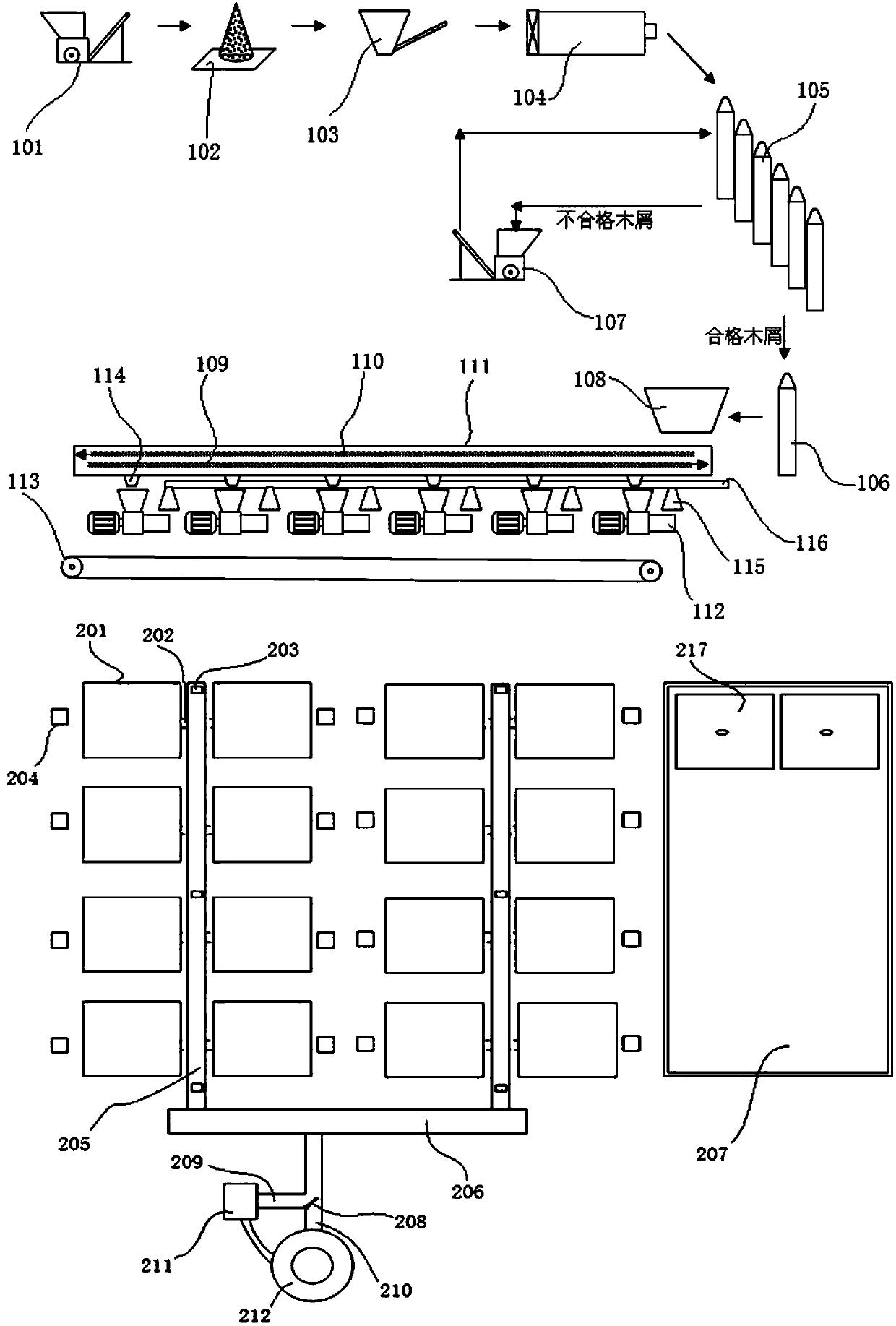

[0020] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the forestry waste rod-making carbonization heating system includes two parts: a rod-making device, a cellar-type charcoal-making combined kiln, and a boiler heating system.

[0021] The rod-making device includes a primary crushing mechanism 101, a fermentation stockyard 102, a feeding mechanism 103, an air-drying mechanism, a screening mechanism and a hot-pressed rod mechanism in sequence:

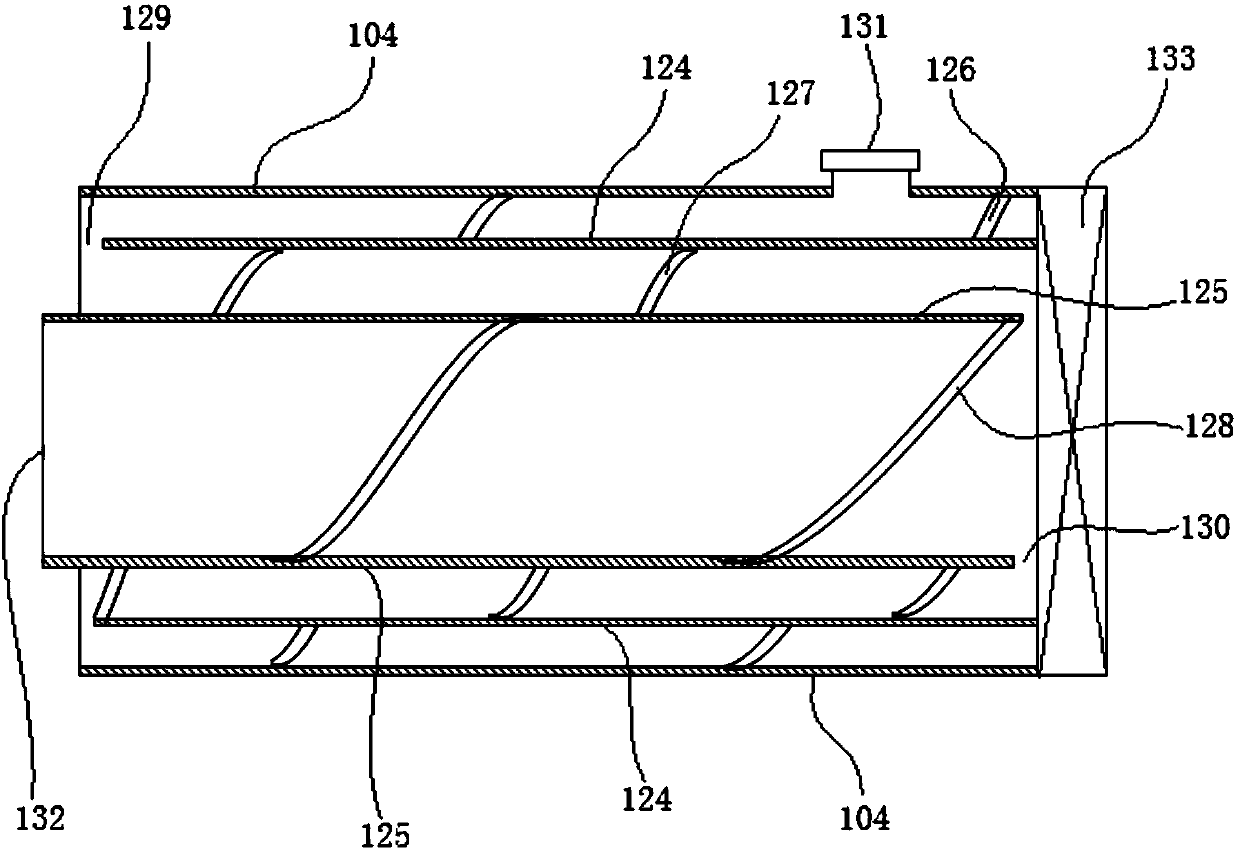

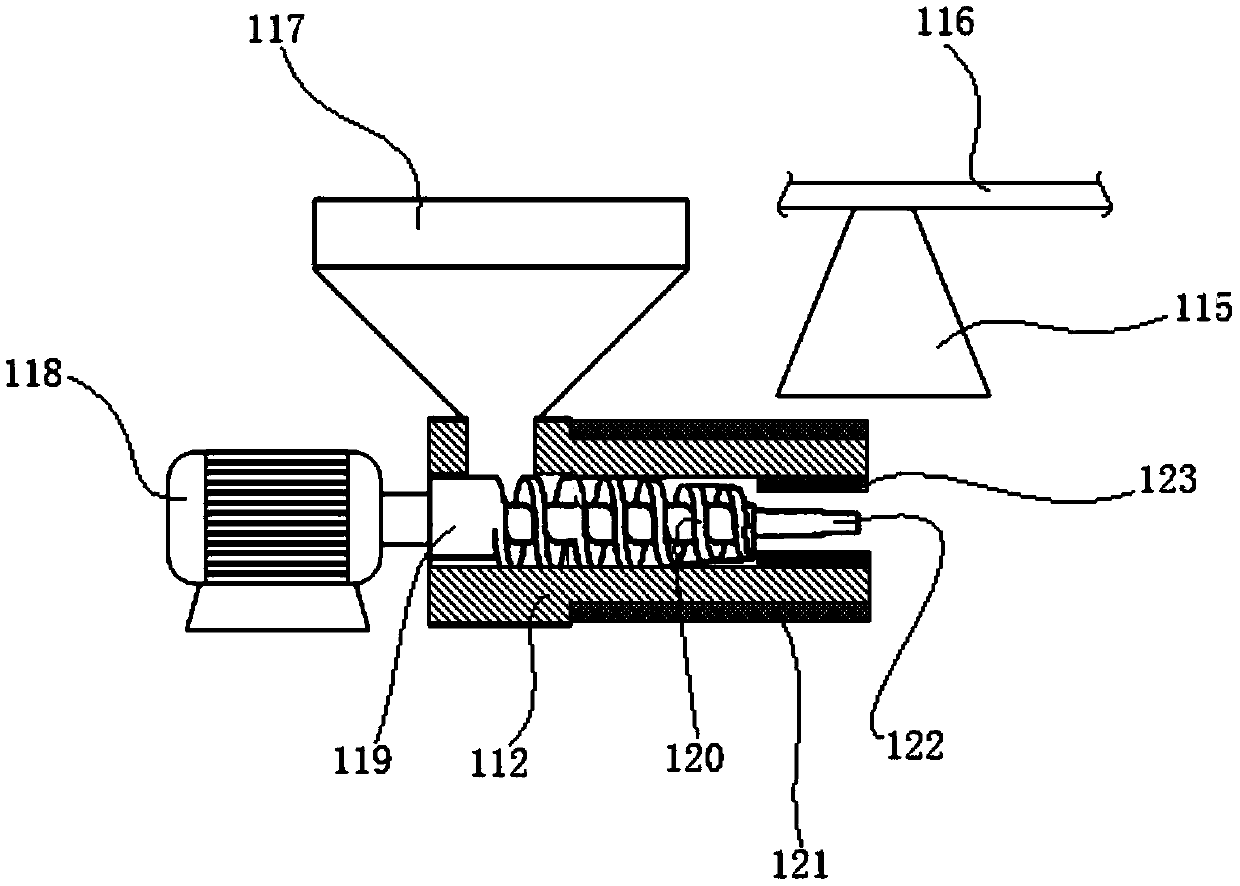

[0022] The primary crushing mechanism 101 includes crushing and crushing equipment for processing forest waste into 18-mesh wood chips; all wood chip grinders on the market are applicable. The fermentation mechanism 102 includes a stacking place for natural fermentation of wood chips, and the fermentation period is seven days. The feeding mechanism 103 includes a feeding hopper and a feeding auger. The fermented sawdust is sent into the feeding hopper, and the feeding auger connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com