Preparation method of a new type of high-rate ternary nickel-cobalt-aluminum power battery

A power battery and nickel-cobalt-aluminum technology, which is applied in the field of preparation of new high-rate ternary nickel-cobalt-aluminum power batteries, can solve the problem of lithium iron phosphate battery gram capacity, inability to improve working voltage, weak battery life, and poor overall battery performance. and other problems, to achieve the effect of being conducive to charging and discharging, increasing electrical conductivity, and excellent low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

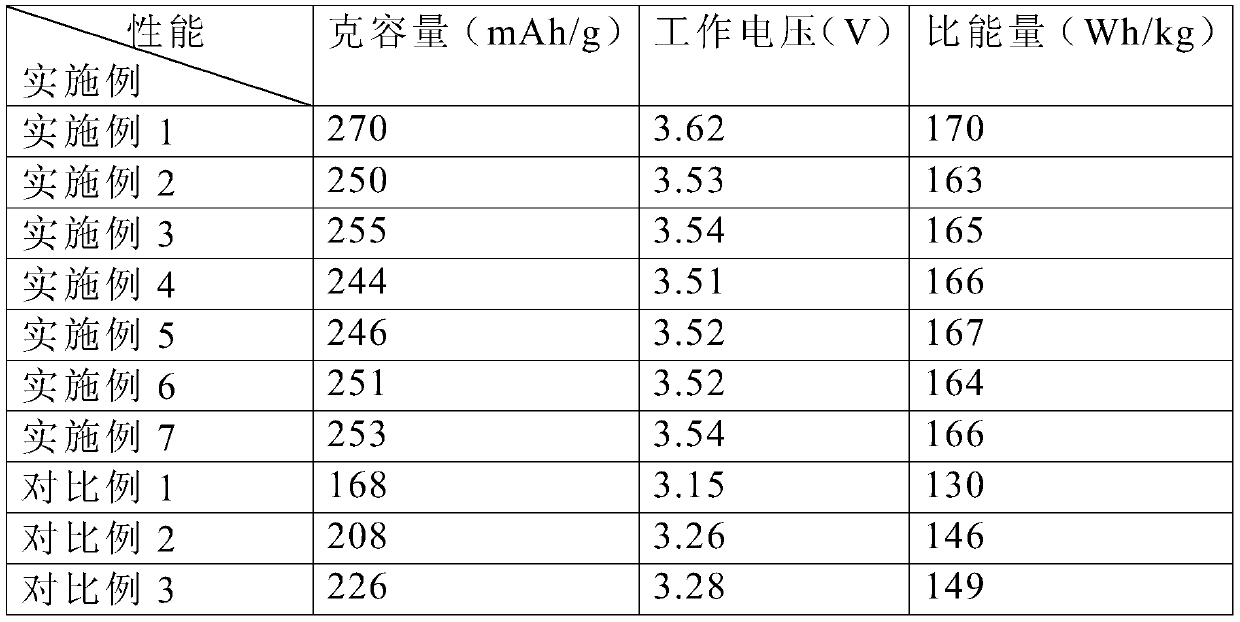

Examples

Embodiment 1

[0030] Ingredients: Prepare the raw materials according to the active material of the above-mentioned battery and its parts by weight. The positive electrode active material includes the following parts by weight: 93 parts of ternary nickel-cobalt-aluminum material, 3.5 parts of positive electrode conductive agent, 4 parts of polyvinylidene fluoride, Wherein, the positive electrode conductive agent includes the following components in parts by weight: 50 parts of graphene, 20 parts of carbon black, 20 parts of large particle graphite powder, and 10 parts of multi-walled carbon nanotubes; the negative electrode active material includes the following components in parts by weight : 92 parts of artificial graphite, 3 parts of water-based binder, 1.5 parts of carbon black, and 3 parts of styrene-butadiene rubber, wherein the water-based binder is sodium carboxymethyl cellulose, and carbon black is a negative electrode conductive agent.

[0031] Preparation of positive electrode act...

Embodiment 2

[0036] Ingredients: Prepare the raw materials according to the active material of the above-mentioned battery and its parts by weight. The positive electrode active material includes the following parts by weight: 90 parts of ternary nickel-cobalt-aluminum material, 3 parts of positive electrode conductive agent, 3 parts of polyvinylidene fluoride, Wherein, the positive electrode conductive agent includes the following components by weight: 45 parts of graphene, 16 parts of carbon black, 16 parts of large particle graphite powder, and 8 parts of multi-walled carbon nanotubes; the negative electrode active material includes the following components by weight : 90 parts of artificial graphite, 2 parts of water-based binder, 1 part of carbon black, and 2 parts of styrene-butadiene rubber, wherein the water-based binder is sodium carboxymethyl cellulose, and carbon black is a negative electrode conductive agent.

[0037] Preparation of positive electrode active material: first mix po...

Embodiment 3

[0042] Ingredients: Prepare the raw materials according to the active material of the above-mentioned battery and its parts by weight. The positive electrode active material includes the following parts by weight: 95 parts of ternary nickel-cobalt-aluminum material, 4 parts of positive electrode conductive agent, 5 parts of polyvinylidene fluoride, Wherein, the positive electrode conductive agent includes the following components by weight: 55 parts of graphene, 24 parts of carbon black, 24 parts of large particle graphite powder, and 12 parts of multi-walled carbon nanotubes; the negative electrode active material includes the following components by weight : 94 parts of artificial graphite, 4 parts of water-based binder, 2 parts of carbon black, and 4 parts of styrene-butadiene rubber, wherein the water-based binder is sodium carboxymethyl cellulose, and carbon black is a negative electrode conductive agent.

[0043] Preparation of positive electrode active material: first mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com