Surface treatment method for improving water resistance, and treatment solution thereof

A technology of surface treatment and water resistance, which is applied in the direction of copying/marking, printing, etc., can solve the problems of short effective life of ink, poor boiling resistance, and falling off of graphics and text, and achieve easy cleaning of the production environment, high production efficiency, The effect of Yilian production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1)

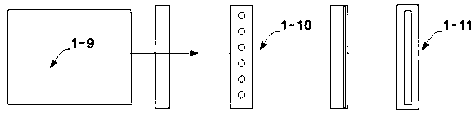

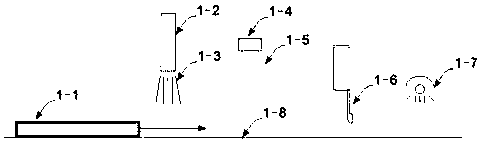

[0055] Embodiment (1): Water-resistant surface treatment is carried out on flat glass. figure 1 The process of the embodiment (1) of the present invention is shown in the form of a process flow module, figure 2 for figure 1 top view. refer to figure 1 with figure 2 , as described below.

[0056] Flat glass (1-1) advances in the direction of the arrow on the production line (1-8).

[0057] Step 1, degreasing. The flame processor (1-2) ejects a high-temperature gas flame (1-3). When the flat glass (1-1) passes by, the grease on the glass surface is burned by the flame; the flame processor generally uses flammable gas (such as natural gas or liquefied petroleum gas) mixed with a combustion-supporting gas (such as air or oxygen) to generate a high-temperature flame. Existing products on the market, such as Rapidflame from the UK and Web Flame treatment from Enercon, have the advantage of a wide range of flame treatment.

[0058] Step 2, activate. The high-pressure spray ...

Embodiment (2)

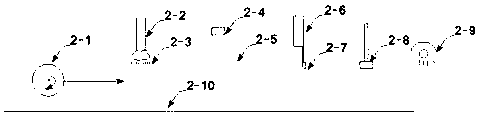

[0061] Embodiment (2): A water-resistant surface treatment is performed on a cylindrical glass container. image 3 The process of embodiment (2) of the present invention is shown in the form of a process flow module, Figure 4 for image 3 top view. refer to image 3 with Figure 4 , as described below.

[0062] The cylindrical glass container wine bottle (2-1) advances in the direction of the arrow on the production line (2-10).

[0063] Step 1, degreasing. The jet plasma processor (2-2) ejects low-temperature plasma (2-3), and when the wine bottle (2-1) passes under the jet plasma processor (2-2), it stops briefly, and the wine bottle (2-1) Rotating 360° with the axis as the center line, the grease on the surface of the bottle is decomposed and gasified under the action of plasma high-energy particles; It can reach 10cm; for ordinary bottles, two rotating plasmas (2-11) can be superimposed to complete the treatment at one time. The existing products on the market are ...

Embodiment (3)

[0071] Embodiment (3): Preparation of activation solution

[0072] Weigh 98g of deionized water, add 0.6g of fumaric acid as a pH adjuster and stir evenly to reduce the pH of the system to about 4.00; add 1g of coupling agent Dow Corning Z-6121, stir evenly and add substrate to wet The dose of Digo wet 250 is 0.4g.

[0073] Sample (1): Glass Transfer

[0074] Prepare a glass sheet sample of 10cm*10cm*0.1cm; use the process described in Example (1) and the activation solution described in Example (3) to carry out surface treatment on the sample; use epoxy system as the adhesive layer The flower film is transferred to the surface of the above sample by a thermal transfer machine; it is finally baked at 150°C for 30 minutes and then tested.

[0075] Sample (2): Glass printing

[0076] Prepare a glass sheet sample of 10cm*10cm*0.1cm; use the process described in Example (1) and the activation solution described in Example (3) to carry out surface treatment on the sample; at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com