An electrochemical gas-filling method and production method of the gas-filling block

An air-entraining block and electrochemical technology, applied in the field of building materials, can solve the problems of difficult and stable control of the air-entraining speed and air-entraining volume, etc., and achieve the effects of good thermal insulation effect, life safety protection, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

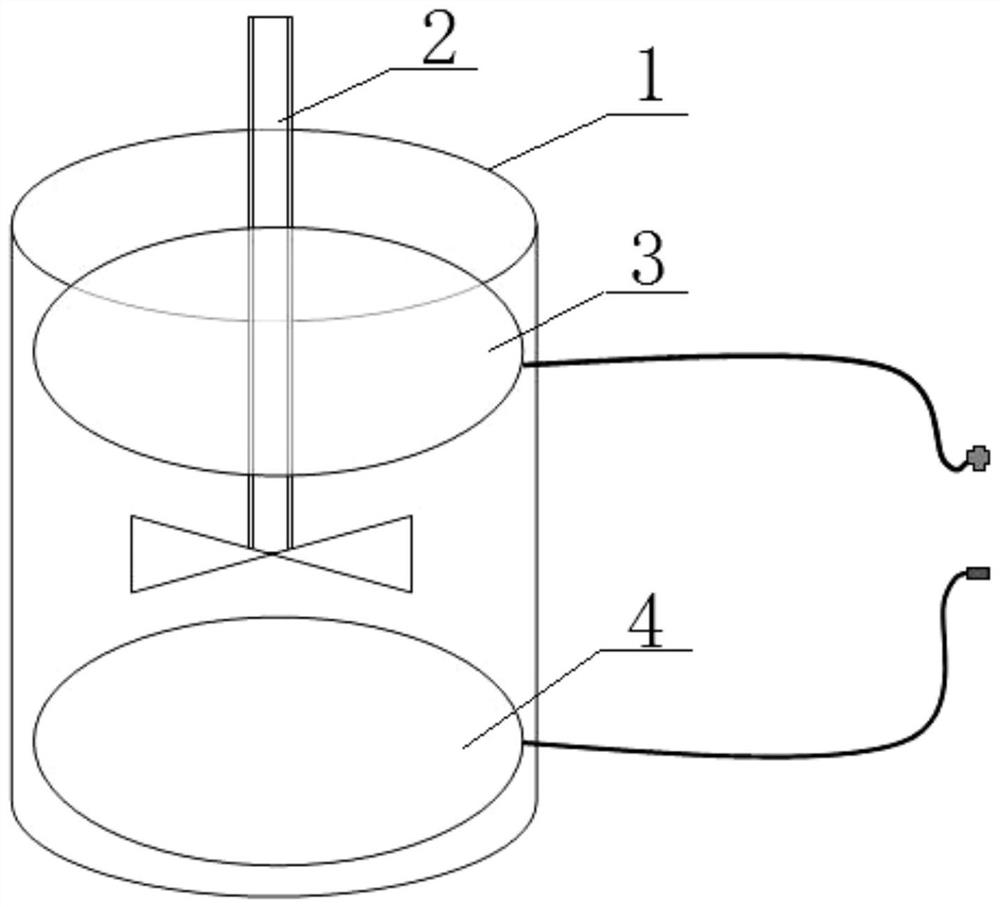

Image

Examples

Embodiment 1-1

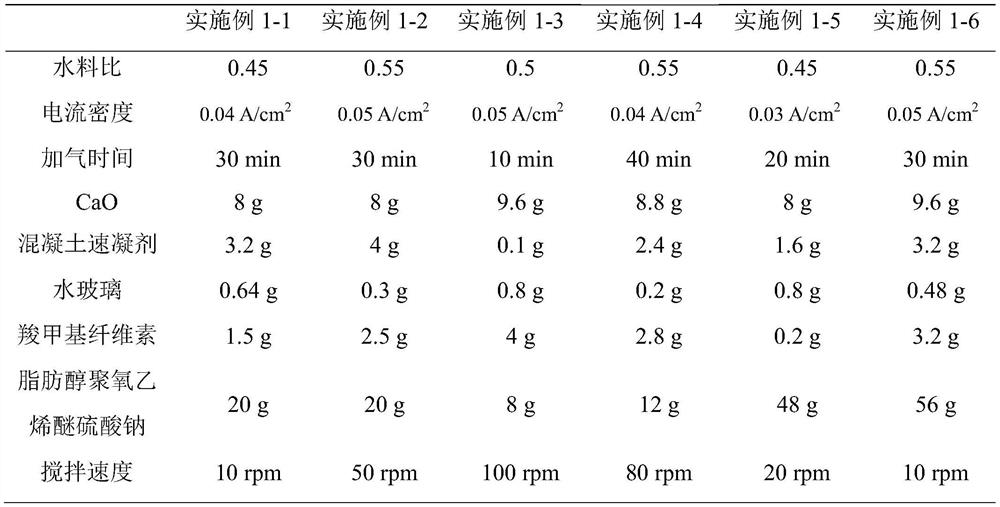

[0039] The relevant process parameters of the present embodiment are shown in Table 1, and the specific steps are: (1) take 8 gram of calcium oxide and add 420 gram of water to digest for 24 hours, then add 3.2 gram of concrete quick-setting agent, 0.64 gram of water glass (modulus: 2.0 ), 1.5 grams of carboxymethyl cellulose and 20 grams of fatty alcohol polyoxyethylene ether sodium sulfate, and stir evenly; (2) take blast furnace slag powder and desulfurization ash according to 1:1, with a total mass of 800 grams, and put them in the cement slurry Stir and mix evenly in the mixer; (3) join the limewater digestion mixed solution in the desulfurization ash and slag mixed powder, adjust the water-material ratio to 0.45, and stir to obtain the microfluidity slurry by the standard method of cement slurry mixing; (4 ) Inject the slurry into the electrolysis device, use a regulated power supply to pressurize the electrolysis, and the current density is 0.04A / cm 2 , time 30 minutes;...

Embodiment 1-2

[0045] The relevant process parameters of the present embodiment are shown in Table 1, and the specific steps are: (1) take 8 gram of calcium oxide and add 420 gram of water to digest for 24 hours, then add 4 gram of concrete quick-setting agent, 0.3 gram of water glass (modulus: 2.2 ), 2.5 grams of carboxymethyl cellulose and 20 grams of fatty alcohol polyoxyethylene ether sodium sulfate, and stir evenly; (2) take blast furnace slag powder and desulfurization ash according to 1:0.8, with a total mass of 800 grams, in the cement slurry Stir and mix evenly in the mixer; (3) add the desulfurized ash and slag micropowder mixed powder to the limewater digestion and stirring mixed solution, adjust the water-material ratio to 0.55, and stir to obtain microfluidity slurry by the standard method of cement slurry mixing; (4 ) Inject the slurry into the electrolysis device with the electrodes installed, use a regulated power supply to pressurize the electrolysis, and the current density ...

Embodiment 1-3

[0047] The relevant process parameters of the present embodiment are shown in Table 1, and the specific steps are: (1) take 9.6 grams of calcium oxide and add 420 grams of water to digest for 24 hours, then add 0.1 gram of concrete quick-setting agent, 0.8 gram of water glass (modulus: 2.2 ), 4 grams of carboxymethyl cellulose and 8 grams of fatty alcohol polyoxyethylene ether sodium sulfate, and stir evenly; (2) take blast furnace slag powder and desulfurization ash according to 1:1, with a total mass of 800 grams, and add them to the cement slurry Stir and mix evenly in the mixer; (3) add the desulfurized ash and slag micropowder mixed powder to the limewater digestion and stirring mixed solution, adjust the water-material ratio to 0.50, and stir to obtain the microfluidity slurry by the standard method of cement slurry mixing; (4 ) Inject the slurry into the electrolysis device with the electrodes installed, use a regulated power supply to pressurize the electrolysis, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com