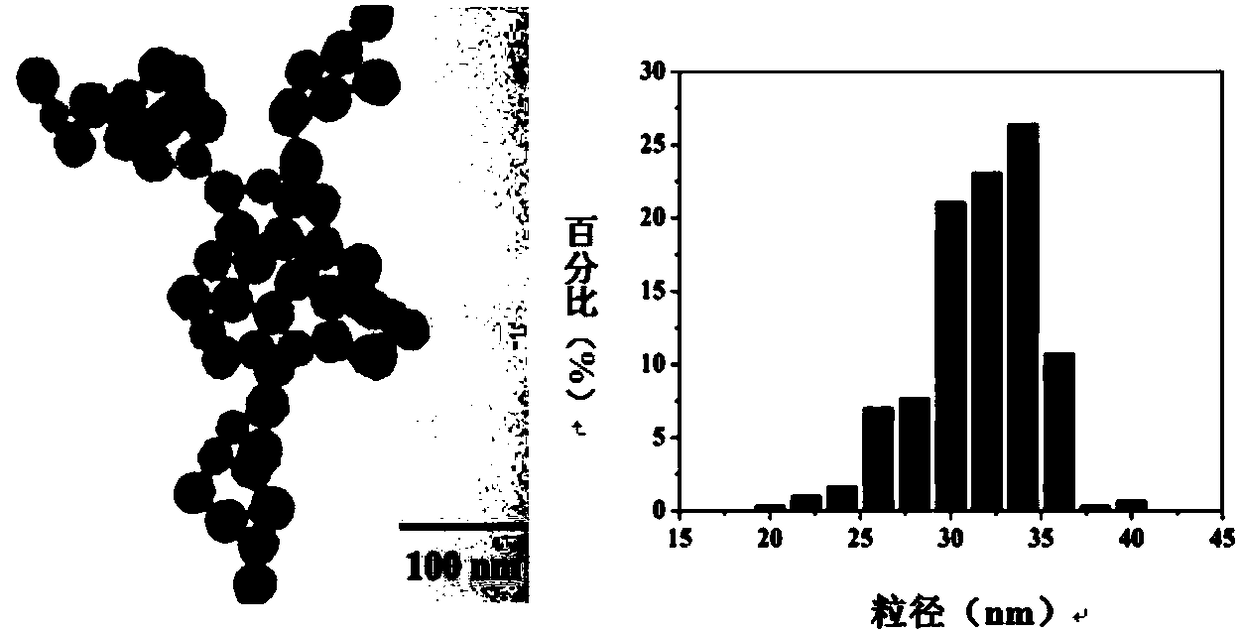

Method for improving solubility of poorly soluble drugs using silicon nanocarriers

A technology of insoluble drugs and silicon nanometers, which is applied in the directions of pharmaceutical formulations, organic active ingredients, and medical preparations of non-active ingredients, etc., can solve the problems of large particle size and difficult cellular uptake, etc., and achieves a simple preparation method and easy purification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Prepare 0.50% ((w / v)) aminopropyltriethoxysilane (APS) aqueous solution as the microemulsion water phase, prepare cetyltrimethylammonium bromide (CTAB), cyclohexane , Triton X-100 and n-octanol mixed solution are microemulsion oil phases, and the distribution ratio of each component is cetyltrimethylammonium bromide (CTAB) 0.15% (w / v), cyclohexane 65.5% (w / v), Triton X-100 18.15% (w / v), n-octanol 16.2% (w / v);

[0031] (2) The oil phase is added into the reactor and stirred at a stirring speed of 400rpm, and the water phase is slowly added to the oil phase to form a water-in-oil inverse microemulsion system, and the ratio of the water phase to the oil phase is 1:20, Continue to stir for 30min to form a stable microemulsion;

[0032] (3) Add tetraethyl orthosilicate (TEOS) and ammonia water to trigger the polymerization reaction, and the addition of tetraethyl orthosilicate (TEOS) and ammonia liquor is 0.45% (w / v) and 0.40% (w / v) of the total volume of the microemul...

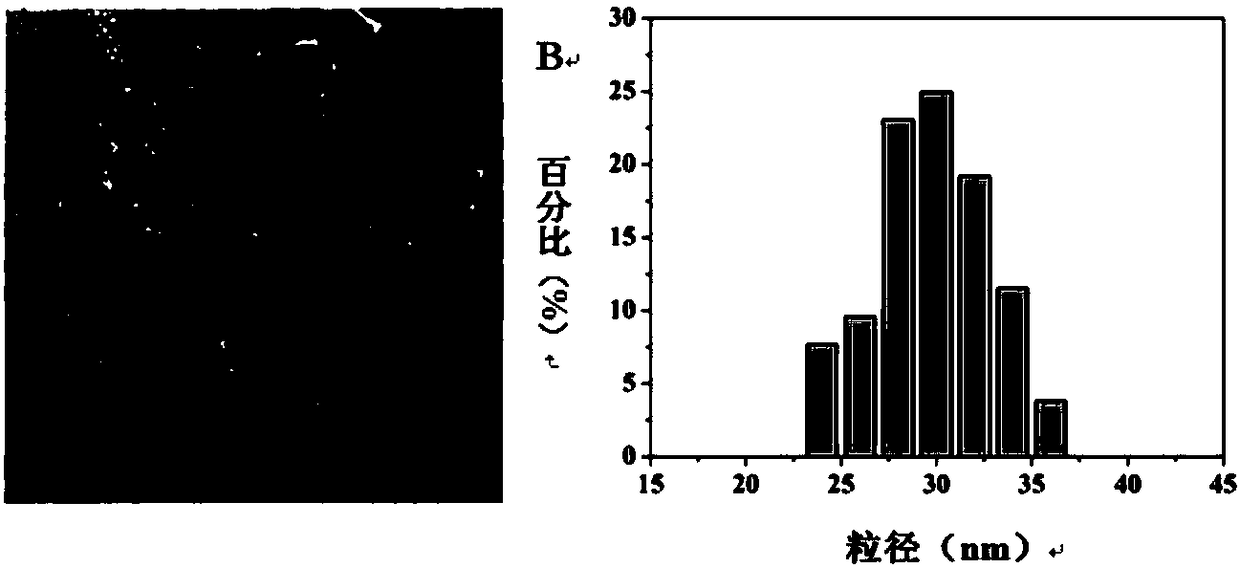

Embodiment 2

[0038] (1) Prepare 1.00% (w / v) aminopropyltriethoxysilane (APS) aqueous solution as the microemulsion water phase, prepare cetyltrimethylammonium bromide (CTAB), cyclohexane, Triton The mixed solution of X-100 and n-octanol is the microemulsion oil phase, and the distribution ratio of each component is cetyltrimethylammonium bromide (CTAB) 0.3% (w / v), cyclohexane 60.00% (w / v) , Triton X-100 21.00% (w / v), n-octanol 18.70% (w / v);

[0039] (2) The oil phase is added into the reactor and stirred, the stirring speed is 300rpm, the water phase is slowly added to the oil phase to form a water-in-oil inverse microemulsion system, the ratio of the water phase to the oil phase is 1:15, Continue to stir for 60min to form a stable microemulsion;

[0040] (3) Add tetraethyl orthosilicate (TEOS) and ammonia water to trigger the polymerization reaction, and the addition of tetraethyl orthosilicate (TEOS) and ammonia liquor is 0.80% (w / v) and 0.70% (w / v) of the total volume of the microemuls...

Embodiment 3

[0046] (1) Prepare 0.40% (w / v) of 3-(methacryloyloxy)propyltrimethoxysilane (MEMO) (the aqueous solution is the microemulsion aqueous phase, prepare hexadecyltrimethylammonium bromide (CTAB), butane, Triton X-100 and n-heptanol mixed solution are the microemulsion oil phase, and the distribution ratio of each component is dodecyl dimethyl benzyl ammonium chloride (DDBAC) 0.2% (w / v), Butane 55.45% (w / v), Triton X-100 19.20% (w / v), n-heptanol 25.15% (w / v);

[0047] (2) The oil phase is added into the reactor and stirred at a stirring speed of 300rpm, and the water phase is slowly added to the oil phase to form a water-in-oil inverse microemulsion system, and the ratio of the water phase to the oil phase is 1:20, Continue to stir for 60min to form a stable microemulsion;

[0048] (3) add tetraethyl orthosilicate (TEOS) and ammoniacal liquor to trigger polymerization reaction, the addition of tetraethylorthosilicate (TEOS) and ammoniacal liquor is 0.40% (w / v) and 0.30% (w / v) of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com