Preparation method of catalyst for methane oxyhalogenation

A methane halogen oxidation and catalyst technology, which is applied in the field of preparation of methane halogen oxidation catalysts, can solve problems such as low yield of methyl halides, reduction of selectivity of methyl halides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

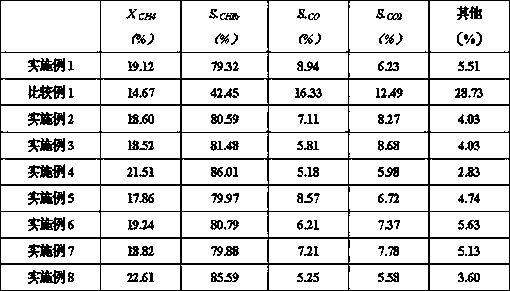

Examples

Embodiment 1

[0028] Preparation of modified silicon oxide: use equal volume impregnation method on silicon oxide (commercially available commodity, properties are as follows: specific surface 335m 2 / g, pore volume is 0.86ml / g) impregnated with lanthanum nitrate and nickel nitrate aqueous solution, the molar concentration of lanthanum and nickel metal ions in the solution is 0.5mol / L, after impregnation, dry and roast, the drying time is 1h, dry The temperature is 100°C; the calcination time is 2h, and the temperature is 900°C;

[0029] Preparation of zinc-loaded silicon oxide: impregnating zinc nitrate solution on the modified silicon oxide by equal-volume impregnation method, drying and roasting after impregnation, the drying time is 2 hours, and the drying temperature is 130 ° C; the roasting time is 4 hours, the temperature 400°C, the silicon oxide loaded with zinc is spherical, and the equivalent diameter of silicon oxide loaded with zinc is 2 mm;

[0030] Prepare aluminum hydroxide ...

Embodiment 2

[0035] Preparation of modified silicon oxide: use equal volume impregnation method on silicon oxide (commercially available commodity, properties are as follows: specific surface 335m 2 / g, pore volume is 0.86ml / g) impregnated with lanthanum nitrate and nickel nitrate aqueous solution, the molar concentration of lanthanum and nickel metal ions in the solution is 1.5mol / L, after impregnation, dry and roast, the drying time is 2h, dry The temperature is 100°C; the calcination time is 8h, and the temperature is 700°C;

[0036] Preparation of zinc-loaded silicon oxide: impregnating zinc sulfate solution on the modified silicon oxide by equal-volume impregnation method, drying and roasting after impregnation, the drying time is 3 hours, and the drying temperature is 120 ° C; the roasting time is 5 hours, the temperature 450°C, the zinc-loaded silicon oxide is spherical, and the equivalent diameter of the zinc-loaded silicon oxide is 2mm;

[0037] Prepare aluminum hydroxide slurry ...

Embodiment 3

[0042] Preparation of modified silicon oxide: use equal volume impregnation method on silicon oxide (commercially available commodity, properties are as follows: specific surface 335m 2 / g, pore volume is 0.86ml / g) impregnated with lanthanum nitrate and nickel nitrate aqueous solution, the molar concentration of lanthanum and nickel metal ions in the solution is 1mol / L, after impregnation, dry and roast, the drying time is 0.5h, dry The temperature is 130°C; the calcination time is 5h, and the temperature is 800°C;

[0043]Preparation of zinc-loaded silicon oxide: impregnating zinc bromide solution on the modified silicon oxide by equal-volume impregnation method, drying and roasting after impregnation, the drying time is 4 hours, and the drying temperature is 100°C; the roasting time is 4 hours, The temperature is 500°C, the zinc-loaded silicon oxide is spherical, and the equivalent diameter of the zinc-loaded silicon oxide is 3mm;

[0044] Prepare aluminum hydroxide slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com