Preparation and application of a heterogeneous asymmetric hydroformylation catalyst

A hydroformylation catalyst and asymmetric technology, which is applied in the direction of carbon monoxide reaction preparation, organic compound preparation, physical/chemical process catalyst, etc., can solve the problems of poor reuse of homogeneous catalysts, influence, unfavorable product purification, etc., to achieve The effect of optimization effect, high chemical stability, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

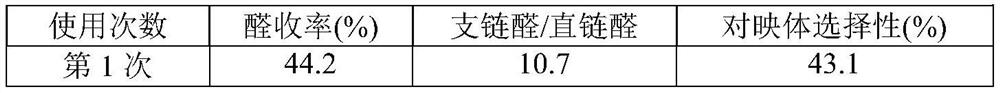

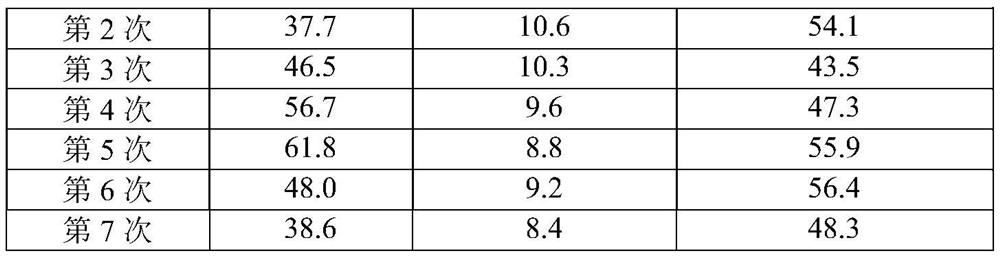

Embodiment 1

[0016] Dissolve 5.0g of (S)-5,5'-divinyl-BINAP ligand in 30mL tetrahydrofuran solvent at 25°C under an inert gas atmosphere, add 10.0g of divinylbenzene monomer, stir well, then slowly add 0.5g free radical initiator azobisisobutyronitrile, stirred for 0.5h, then transferred the solution to a polytetrafluoro-lined kettle, and solvothermally polymerized at 100°C for 24h. After the reaction, the reaction product was vacuum-dried at 65° C. for 10 h to obtain a porous chiral polymer. Take 0.044g Rh(CO) 2 (acac) was dissolved in 8mL of N,N-dimethylformamide solvent, 2.4g of polymer material was added, and stirred at 100°C for 3h under an inert gas atmosphere. Then vacuum dry at 75°C for 10 h. That is, heterogeneous asymmetric hydroformylation catalyst 1.

Embodiment 2

[0018] In Example 2, except that 10.0 g of divinylbenzene was replaced by 10.0 g of styrene, other operations were the same as in Example 1 to prepare Catalyst 2.

Embodiment 3

[0020] In Example 3, except that 10.0 g of divinylbenzene was replaced by 10.0 g of 1,3,5-tris(p-vinylphenyl)benzene, the rest of the operations were the same as in Example 1 to prepare Catalyst 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com