Pollution intercepting type water permeable brick and preparation method thereof

A technology of permeable bricks and cement is applied in the field of green building materials to achieve the effects of large adsorption capacity, improved adsorption performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

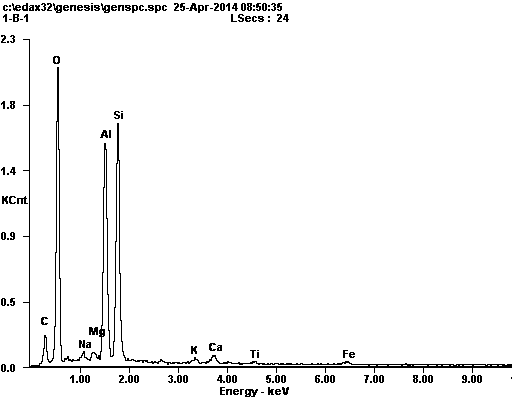

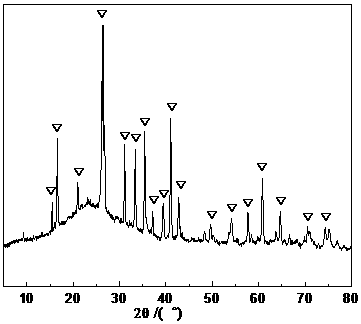

[0032] Crush the fly ash and zeolite to a particle size of 200-300 mesh, wash with water for 30 minutes, and then freeze-dry for 36 hours; crush the corn stalks to a particle size of less than 3mm, according to the mass ratio of 70:5:10:0.5:0.5 : 1: 0.5: 0.5 Weigh fly ash, biomass, zeolite powder, aluminum phosphate, magnesium aluminum hydrotalcite, bentonite, cement and magnesium lignosulfonate and mix evenly, add 10% of the total weight of the mixture in clean water , after mixing evenly, aging at 4°C for 12 hours, pressurized with a water-permeable stainless steel mold of 30×50×15cm, air-dried for 4 hours, dried at 105°C for 12 hours, and then heated at 600°C under the condition of nitrogen gas Roasted in a muffle furnace for 2 hours, and then cooled to room temperature with the furnace to obtain the finished sewage intercepting permeable brick. attached by figure 1 The SEM image of the permeable brick shows that the permeable brick is a smooth spherical particle with irre...

Embodiment 2

[0036] Crush the fly ash and sepiolite to a particle size of 200-300 mesh, wash them with clean water for 30 minutes, and then freeze-dry them for 48 hours; crush the rice husks to a particle size of less than 3mm, according to the mass ratio of 85:10:20:3 : 3:3:1:1 Weigh fly ash, biomass, sepiolite powder, aluminum phosphate, magnesium-aluminum hydrotalcite, bentonite, cement and quartz powder and mix evenly, add 5% of the total weight of the mixture in purified water , after stirring evenly, aging at 6°C for 24h, pressurized with a water-permeable stainless steel mold of 30×30×10cm, air-dried for 8h, dried at 120°C for 8h, and then heated at 400°C under the condition of nitrogen gas Roasted in a muffle furnace for 4 hours, and then cooled to room temperature with the furnace to obtain the finished sewage intercepting permeable brick.

[0037] Strength and water permeability test: Strength and water permeability test: According to the provisions of Appendix A in "Permeable Br...

Embodiment 3

[0040] The permeable brick prepared in Example 2 was soaked in 5mol / L hydrochloric acid for 24 hours after adsorption saturation, then rinsed with water until neutral, dried at 120°C for 12 hours, and then placed in a horse at 600°C under the condition of nitrogen gas. Furnace roasting 4h, with the furnace to cool to room temperature. attached by Figure 4 According to the SEM images of the regenerated permeable bricks, the water channels and particles of the regenerated permeable bricks have slight changes, the strength and water permeability of the permeable bricks change within 1%, and the adsorption capacity recovers to more than 95% of the newly prepared permeable bricks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average compressive strength | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com