Silicon nitride gradient porous capillary core for loop heat pipe and preparation method thereof

A gradient porous, loop heat pipe technology, used in applications, ceramic products, household appliances, etc., can solve the problems of single, complex processing, etc., and achieve the effects of simple preparation process, large capillary suction, and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

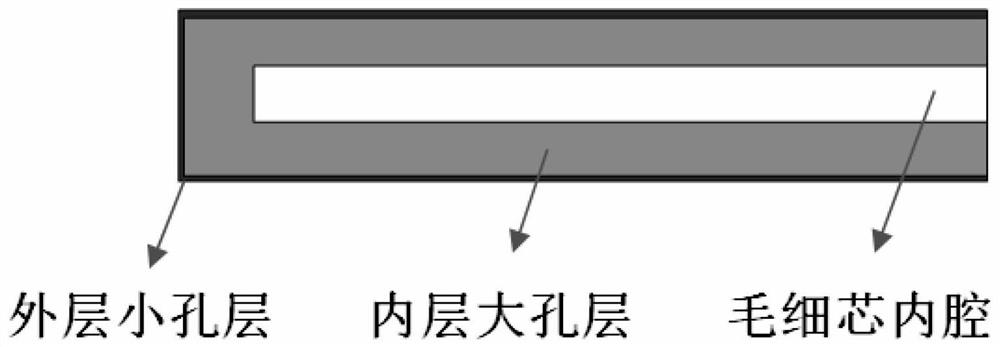

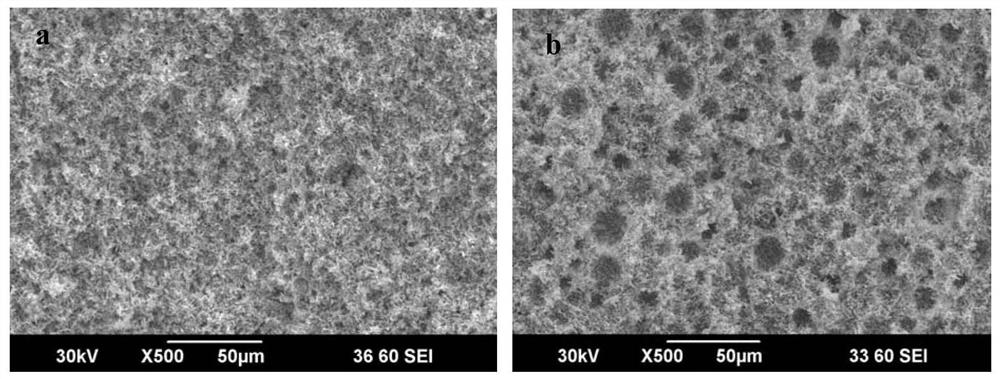

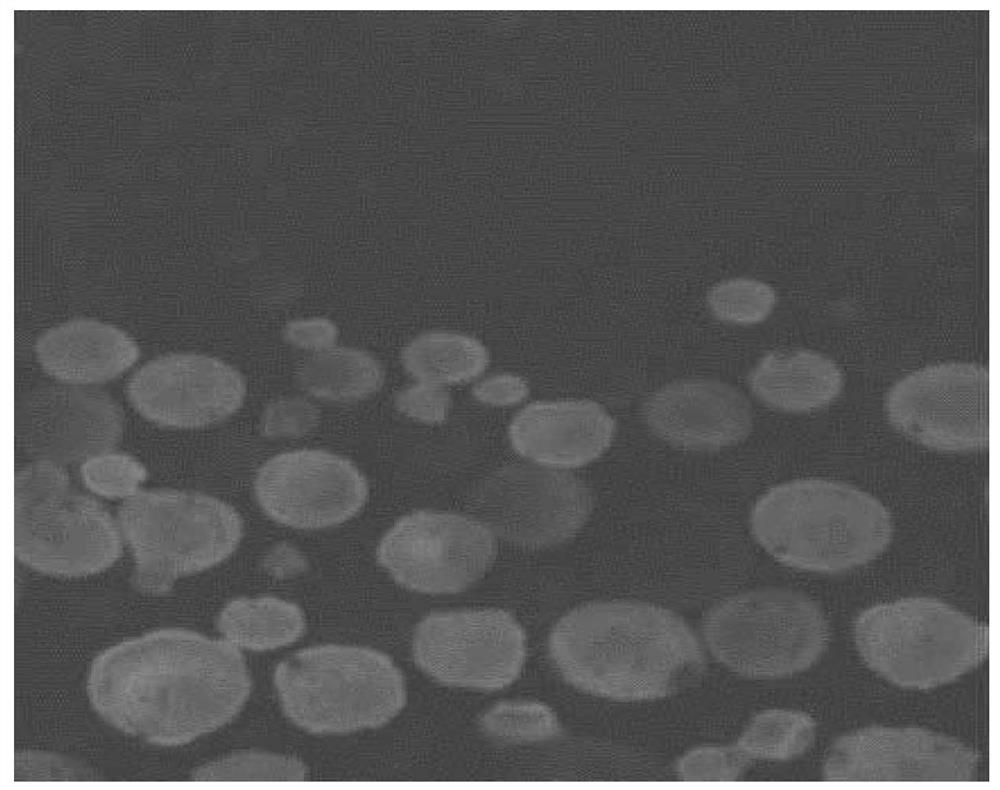

[0036] Preparation of slurry. Specifically, the silicon nitride ceramic slurry is prepared, and the silicon nitride powder, sintering aid, gelling agent, and pore former are sequentially added to deionized water, and mixed by ball milling to obtain a uniformly mixed slurry . Wherein, the mass ratio of the silicon nitride powder (generally 0.3-0.8 microns), sintering aid, gelling agent, pore former and water may be 100: (0.5-10): (0.1-5): (1~50): (20~300). The present invention controls the amount or type of pore-forming agent added in the slurry, and thereby regulates the colloidal porosity after solidification of the slurry gel, and finally controls the nitridation in the obtained silicon nitride gradient porous capillary core for loop heat pipes. The pore size and porosity of the silicon macroporous layer and the silicon nitride small porous layer. Control the mass ratio of silicon nitride powder, sintering aid, gelling agent, pore former and water to 100: (0.5~10): (0.1~5...

Embodiment 1

[0043] (1) Add 100g of silicon nitride balls, 40g of deionized water, 2.5g of sintering aid yttrium oxide, 47.5g of silicon nitride powder and 1g of gelatin to the two ball mill tanks. The speed of the ball mill is 350rpm. A water-based slurry is obtained after 2 hours of ball milling;

[0044] (2) Add 2g and 20g of cyclohexane to the two tanks of slurry respectively, and continue ball milling for 1 hour to obtain two slurries with different pore former contents, numbered 1 and 2 respectively;

[0045] (3) Pour the No. 1 slurry into the plaster mold, pour out the excess slurry after curing at 25°C for 3 minutes, continue pouring the No. 2 slurry, cure it at 25°C for 1 hour, and wait for the gel to get Ceramic wet body with double pore structure with large pores in the inner layer and small pores in the outer layer;

[0046] (4) After demolding the wet body, dry it at room temperature for 48 hours to obtain a ceramic body;

[0047] (5) Raise the ceramic body in a nitrogen atmosphere a...

Embodiment 2

[0049] (1) Add 100g of silicon nitride balls, 40g of deionized water, 2.5g of sintering aid yttrium oxide, 47.5g of silicon nitride powder and 0.2g of gelling agent isobutylene-maleic anhydride into the two ball mills. The speed of the ball mill is 350 rpm, and the water-based slurry is obtained after 2 hours of ball milling;

[0050] (2) Add 0g and 20g starch to the two tanks of slurry respectively, and continue ball milling for 1 hour to obtain two slurries with different pore former contents, numbered 1 and 2 respectively;

[0051] (3) Pour the No. 1 slurry into the plaster mold, pour out the excess slurry after curing for 1 minute at 25°C, continue to pour the No. 2 slurry, cure it at 25°C for 2 hours, and wait for the gel to get Ceramic wet body with double-layer pore structure with large pores in the inner layer and small pores in the outer layer;

[0052] (4) After demolding the wet body, dry it at room temperature for 48 hours to obtain a ceramic body;

[0053] (5) Raise the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com