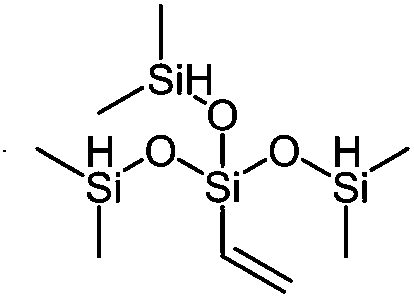

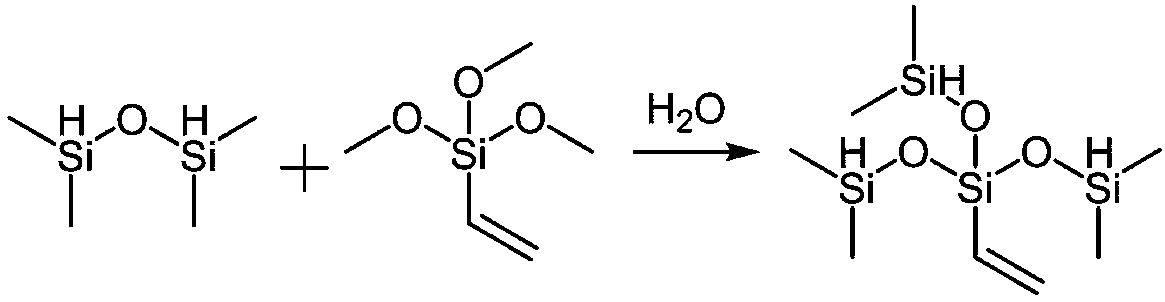

Preparation method of vinyl tri(dimethyl siloxane) silane

The technology of vinyltrimethoxysilane and dimethylsiloxane is applied in the field of preparation of vinyltrisilane, which can solve the problems of reducing product yield, hydrolysis of raw materials, slow reaction and the like, and achieves easy temperature control and reaction. The effect of mild temperature and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

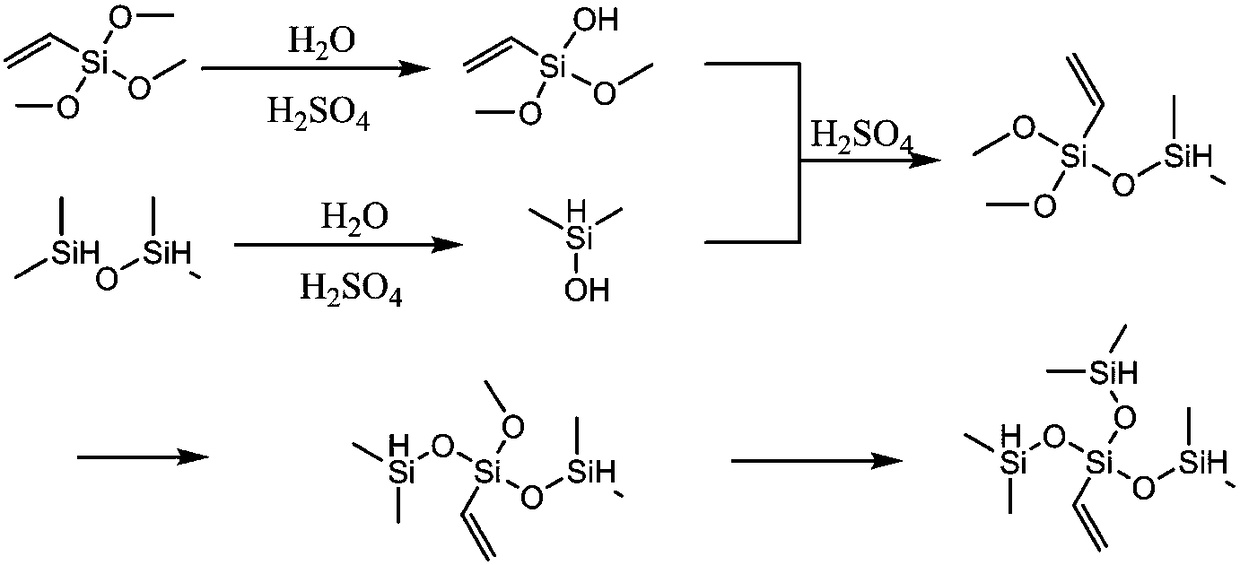

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 5g of concentrated sulfuric acid, 64g of methanol, and 81g of water into a 1000mL three-necked flask equipped with a magnetic stirrer, a thermometer, a condenser tube, and an oil bath heating device to obtain a mixed solution A, and add 268.7g of tetramethyl Disiloxane, stirred and heated up to 40°C to react to obtain mixed solution B;

[0033] (2) Add 74g of vinyltrimethoxysilane dropwise to the mixed solution B to continue the reaction for 2h, the reaction is completed to obtain the mixed solution C, and the gas chromatography detects the reaction situation, wherein the product content is 60%;

[0034] (3) The mixed solution C is separated, washed twice with 500g of water, and the supernatant is filtered after drying with anhydrous magnesium sulfate for 3h, and the filtrate is transferred to the distillation equipment, and the solvent methanol is separated by atmospheric distillation first, and the Pressure distillation separated the front fraction and the pro...

Embodiment 2

[0036] (1) Add 0.33g of hydrochloric acid, 16g of methanol, and 36g of water into a 1000mL three-neck flask equipped with a magnetic stirrer, a thermometer, a condenser tube, and an oil bath heating device to obtain a mixed solution A, and add 201.5g of tetramethyl Disiloxane, stirred and heated to 20°C to react to obtain mixed solution B;

[0037] (2) Add 74g of vinyltrimethoxysilane dropwise to the mixed solution B to continue the reaction for 6h. After the reaction is completed, the mixed solution C is obtained. The reaction situation is detected by gas chromatography, and the product content is 48%;

[0038] (3) The mixed solution C is separated, washed twice with 500g of water, and the supernatant is filtered after drying with anhydrous magnesium sulfate for 3h, and the filtrate is transferred to the distillation equipment, and the solvent methanol is separated by atmospheric distillation first, and the Pressure distillation separated the front fraction and the product, a...

Embodiment 3

[0040] (1) Add 7.4g sodium methoxide, 160g methanol, and 108g water into a 1000mL three-neck flask equipped with magnetic stirring, thermometer, condenser and oil bath heating device to mix to obtain mixed solution A, and add 403g tetramethyl Disiloxane, stirred and heated up to 50°C for reaction to obtain mixed solution B;

[0041] (2) Add 74g of vinyltrimethoxysilane dropwise to the mixed solution B to continue the reaction for 3h. After the reaction is completed, the mixed solution C is obtained. The reaction situation is detected by gas chromatography, and the product content is 37%;

[0042] (3) The mixed solution C is separated, washed twice with 500g of water, and the supernatant is filtered after drying with anhydrous magnesium sulfate for 3h, and the filtrate is transferred to the distillation equipment, and the solvent methanol is separated by atmospheric distillation first, and the Pressure distillation is separated front cut and product, and remaining high-boiling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com