A kind of preparation method of fluorine-containing polyether modified organosilicon polyol

A technology of fluorine-containing polyether and silicone, which is applied in the field of polymer material intermediates, can solve the problems of poor water resistance and weather resistance, etc., and achieve the effect of simple, efficient and easy control of the process, increasing functionality, and facilitating large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

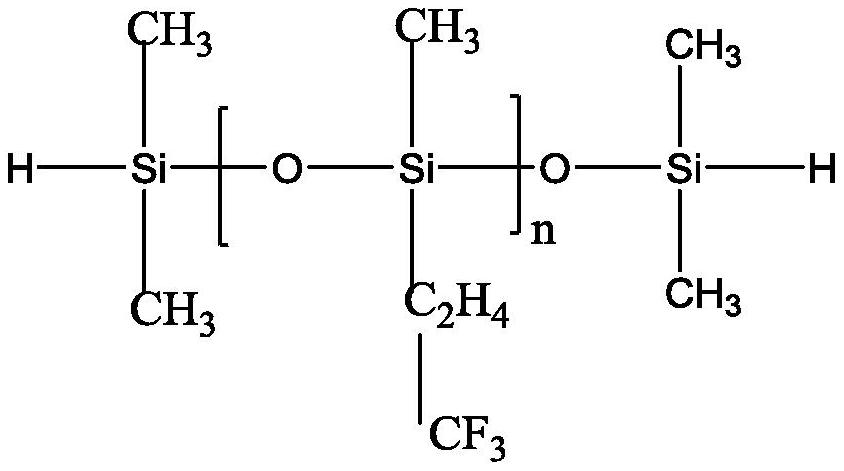

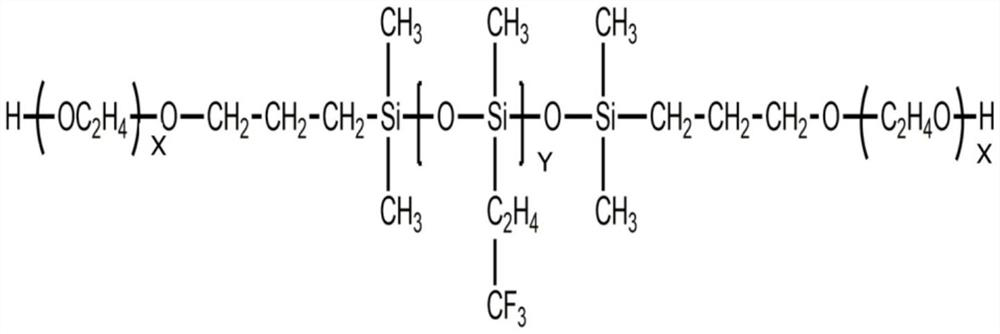

[0029] The preparation steps of a kind of fluorine-containing polyether modified silicone polyol are as follows:

[0030] Step 1: Accurately weigh 861g and 1382g of the dried and dehydrated allyl polyether (Mn=420g / mol) and terminal hydrogen-containing fluorosilicone oil (Mn=1382g / mol), respectively, and add a thermometer and stirring device to the reaction In the container, stir evenly under the protection of nitrogen;

[0031] Step 2: Turn on the heating, raise the temperature to 80°C, add 2.2g of Speier-type platinum catalyst (0.5% platinum catalyst isopropanol solution), continue to slowly raise the temperature to 100°C, and catalyze the reaction at constant temperature for 5 hours;

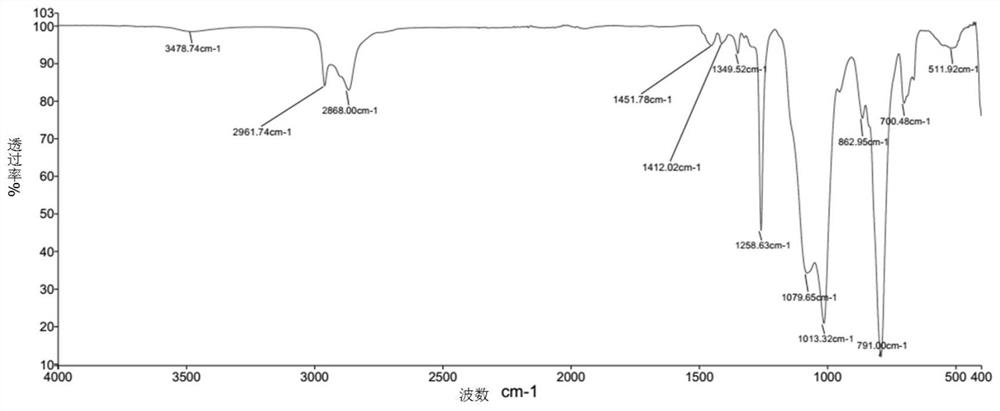

[0032] Step 3: Take a sample and conduct infrared analysis quickly to ensure that there is no characteristic peak of Si-H bond in the infrared spectrum, turn on the vacuum device, reduce the pressure to -0.1Mpa, distill under reduced pressure for 2 hours, remove 67.29g of low boiling substanc...

Embodiment 2

[0034] The preparation steps of a kind of fluorine-containing polyether modified silicone polyol are as follows:

[0035] Step 1: Accurately weigh 976.1g and 1694g of the dried and dehydrated allyl polyether (Mn=454g / mol) and terminal hydrogen-containing fluorosilicone oil (Mn=1694g / mol), respectively, and add the In the reactor, stir evenly under nitrogen protection;

[0036] Step 2: Turn on the heating, raise the temperature to 70°C, add 2.67g of Karsredt-type platinum catalyst (platinum water with a mass fraction of 3000ppm), continue to slowly raise the temperature to 90°C, and carry out constant temperature catalytic reaction for 6 hours;

[0037] Step 3: Take a sample and conduct infrared analysis quickly to ensure that there is no characteristic peak of Si-H bond in the infrared spectrum, turn on the vacuum device, reduce the pressure to -0.1Mpa, distill under reduced pressure for 3 hours, remove 93.45g of low boiling substances, and return to normal pressure Then add ...

Embodiment 3

[0039] The preparation steps of a kind of fluorine-containing polyether modified silicone polyol are as follows:

[0040] Step 1: Accurately weigh 596.2g and 1003g of the dried and dehydrated allyl polyether (Mn=542g / mol) and terminal hydrogen-containing fluorosilicone oil (Mn=2006g / mol), respectively, and add them to a tank equipped with a thermometer and a stirring device In the reactor, stir evenly under nitrogen protection;

[0041] Step 2: Turn on the heating, raise the temperature to 75°C, add 3.2g of Speier-type platinum catalyst (0.5% platinum catalyst in isopropanol solution), continue to slowly raise the temperature to 110°C, and catalyze the reaction at constant temperature for 4.5h;

[0042] Step 3: Take a sample and conduct infrared analysis quickly to ensure that there is no characteristic peak of Si-H bond in the infrared spectrum, turn on the vacuum device, reduce the pressure to -0.1Mpa, distill under reduced pressure for 2 hours, remove 52.77g of low boiling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com