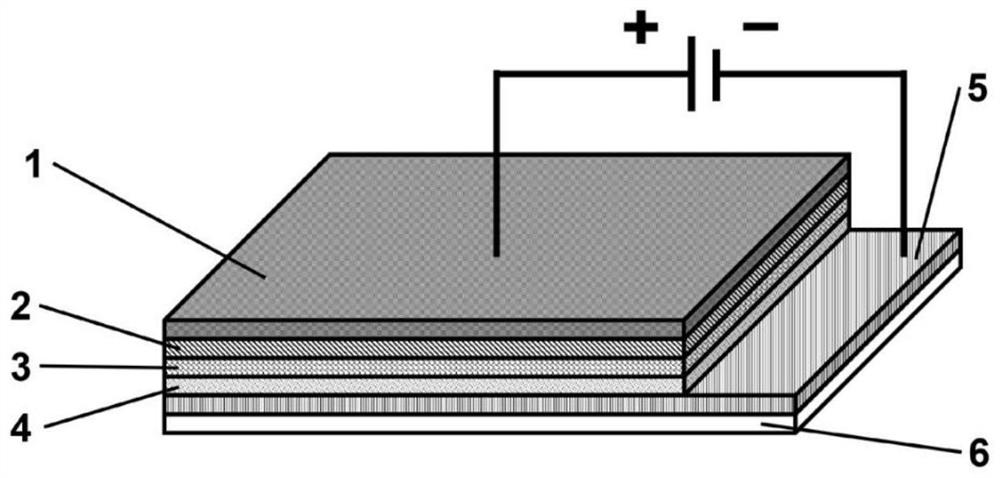

A light-emitting diode based on cesium lead halide perovskite thin film material and its preparation method

A light-emitting diode, cesium-lead-halide technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of quantum dot life, carrier injection, performance and life of light-emitting diodes, etc., to achieve good crystal quality and Effects of optical quality, high injection current and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a cesium lead halide perovskite thin film material, comprising the following steps:

[0036] A) Mix cesium halide and lead halide containing the same halogen elements and grind to obtain mixed powder;

[0037] B) Put the mixed powder in a CVD tube furnace, feed the carrier gas, place the substrate in the downstream direction of the carrier gas, under the condition of 100~200Pa, at a speed of 10~30°C / min The temperature in the furnace cavity of the tube furnace is raised to 500-700° C., kept for 5-30 minutes, and then lowered, and a cesium lead halide perovskite thin film material grows on the surface of the substrate.

[0038] In the invention, cesium halide and lead halide containing the same halogen element are firstly mixed and then ground to obtain mixed powder.

[0039] Wherein, the cesium halide (CsX) is selected from cesium chloride, cesium bromide or cesium iodide; the lead halide (PbX 2 ) is selected from lead chl...

Embodiment 1

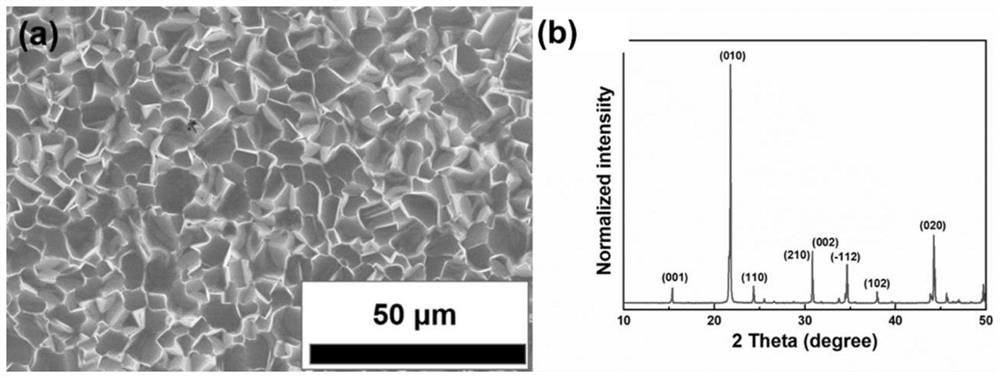

[0079] cesium bromide and lead bromide (CsBr and PbBr 2 ) were mixed together in a molar ratio of 2:1 and ground to a homogeneous powder. The mixed powder was loaded into a ceramic boat and placed in a CVD tube furnace. Place the glass substrate in the downstream direction of the gas flow of the ceramic boat carrying the raw powder in the tube furnace. First, the air pressure in the tube furnace was pumped to 30 Pa with a mechanical pump, and then 250 sccm of high-purity argon (99.99%) was introduced into the furnace cavity as the protective gas and carrier gas. After feeding argon, the air pressure in the furnace chamber was maintained at 140 Pa. The temperature in the tube furnace chamber was raised to 600° C. at a speed of 20° C. / min and kept for 15 minutes. After the growth is completed, stop the heating, let the furnace chamber cool down naturally, and maintain the growth airflow and air pressure until the temperature in the furnace chamber drops below 150°C. The thic...

Embodiment 2

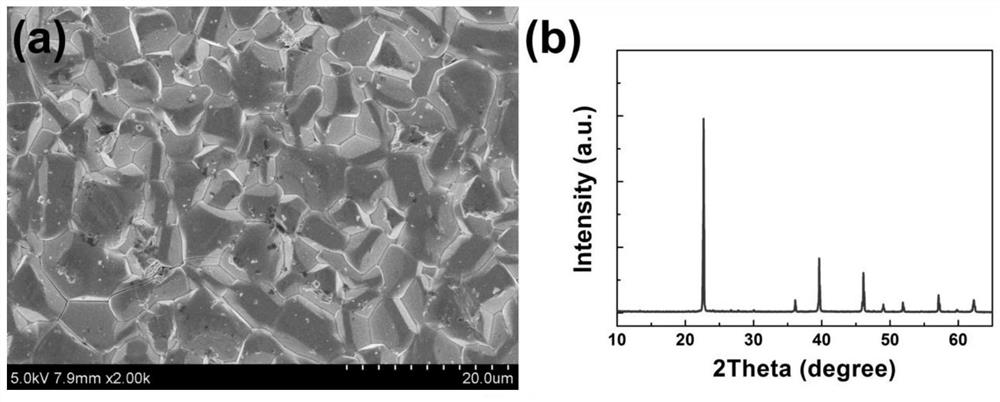

[0082] cesium chloride and lead chloride (CsCl and PbCl 2 ) were mixed together in a molar ratio of 2:1 and ground to a homogeneous powder. The mixed powder was loaded into a ceramic boat and placed in a CVD tube furnace. Place the glass substrate in the downstream direction of the gas flow of the ceramic boat carrying the raw powder in the tube furnace. First, the air pressure in the tube furnace was pumped to 40 Pa with a mechanical pump, and then 300 sccm of high-purity argon (99.99%) was introduced into the furnace cavity as a protective gas and carrier gas. After feeding argon, the air pressure in the furnace chamber was maintained at 150 Pa. The temperature in the tube furnace chamber was raised to 600° C. at a speed of 20° C. / min and kept for 15 minutes. After the growth is completed, stop the heating, let the furnace chamber cool down naturally, and maintain the growth airflow and air pressure until the temperature in the furnace chamber drops below 150°C. The thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com