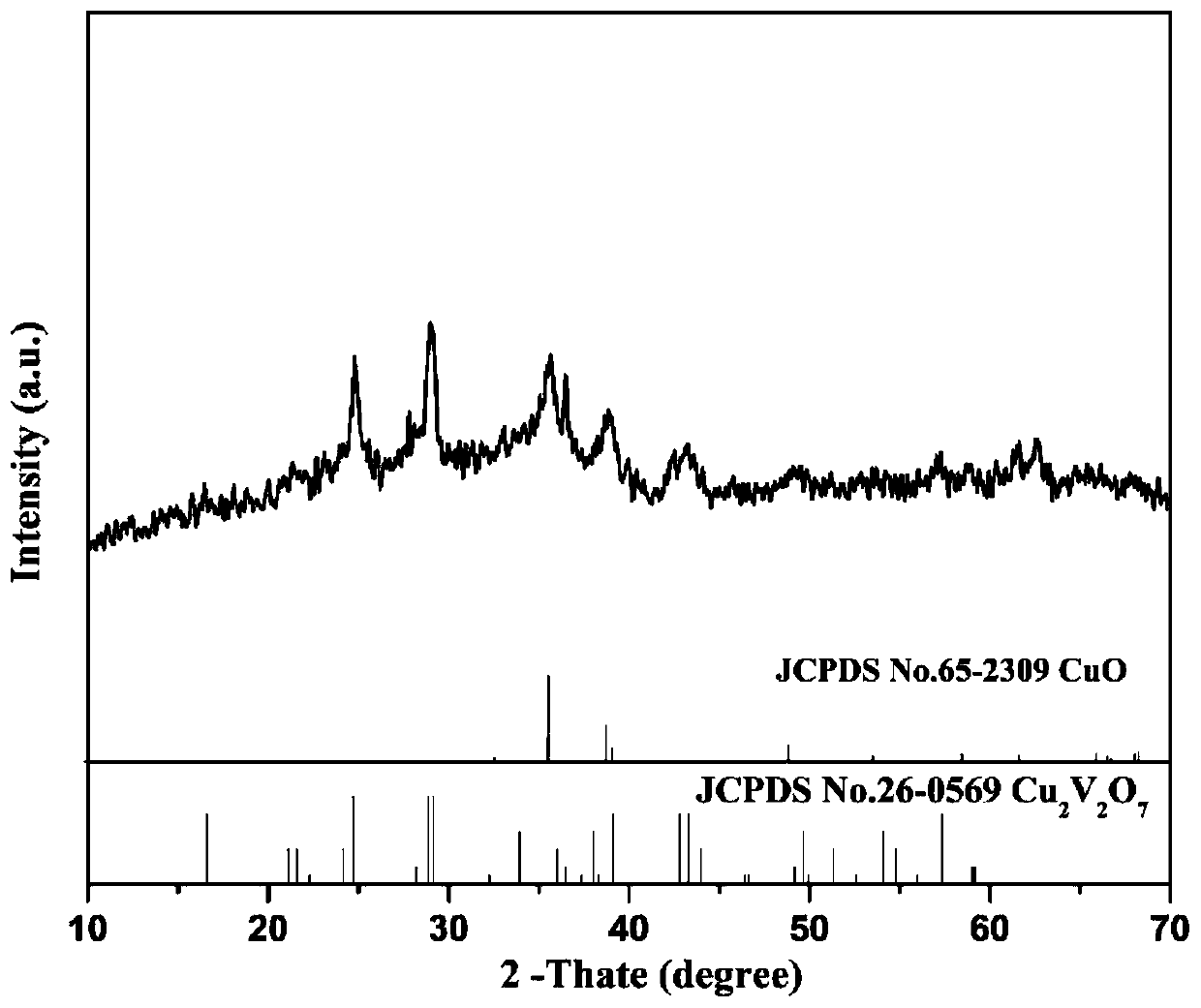

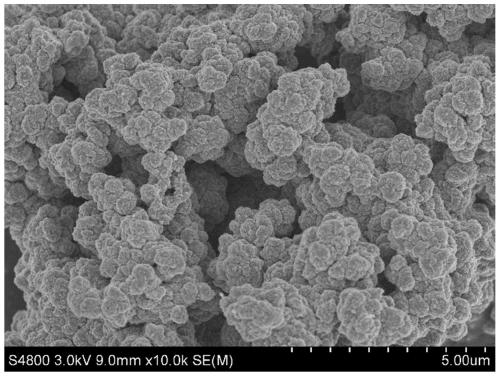

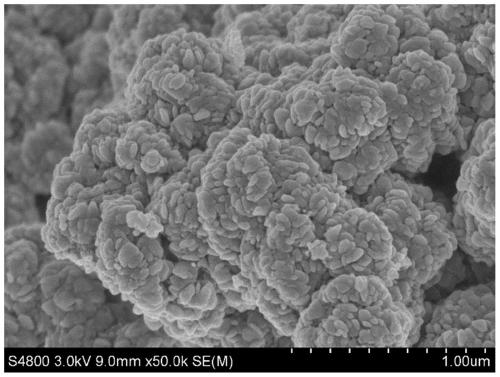

Preparation of cu by a microwave hydrothermal method 2 v 2 o 7 -cuo nanocomposite approach

A nanocomposite, microwave hydrothermal method technology, which is applied in the field of preparing Cu2V2O7-CuO nanocomposite by microwave hydrothermal method, can solve the problems of affecting battery cycle stability, generating large stress, large product size, etc., and achieving the preparation cycle Short, crystalline, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Press V 5+ and Cu 2+ With a molar ratio of 1:0.5, analytically pure V 2 o 5 The powder is dispersed in 0.1mol / L CuCl 2 in aqueous solution;

[0020] 2) Under magnetic stirring, use ammonia water to adjust the pH of the solution to 7, and continue stirring to form a reaction precursor;

[0021] 3) Pour the reaction precursor into a microwave hydrothermal reaction kettle. After the equipment is ready, place it in a microwave hydrothermal instrument with a power of 400W, and conduct a microwave hydrothermal reaction at 100°C for 1 hour. After the reaction is completed and the instrument is automatically cooled, vacuum pump filtered, washed three times with deionized water and absolute ethanol, placed in a vacuum oven at 250°C, and dried for 2 hours to obtain Cu 2 V 2 o 7 -CuO nanocomposites.

Embodiment 2

[0023] 1) Press V 5+ and Cu 2+ With a molar ratio of 1:2, analytically pure V 2 o 5 Powder dispersed in 0.5mol / L CuCl 2 in aqueous solution;

[0024] 2) Under magnetic stirring, use ammonia water to adjust the pH of the solution to 8, and continue stirring to form a reaction precursor;

[0025] 3) Pour the reaction precursor into a microwave hydrothermal reaction kettle. After the equipment is ready, place it in a microwave hydrothermal instrument with a power of 400W, and conduct a microwave hydrothermal reaction at 150°C for 2 hours. After the reaction is completed and the instrument is automatically cooled, vacuum pump filtered, washed three times with deionized water and absolute ethanol, placed in a vacuum oven at 300°C, and dried for 1 hour to obtain Cu 2 V 2 o 7 -CuO nanocomposites.

Embodiment 3

[0027] 1) Press V 5+ and Cu 2+ With a molar ratio of 1:1, analytically pure V 2 o 5 Powder dispersed in 1mol / L CuCl 2 in aqueous solution;

[0028] 2) Under magnetic stirring, use ammonia water to adjust the pH of the solution to 9, and continue stirring to form a reaction precursor;

[0029] 3) Pour the reaction precursor into a microwave hydrothermal reaction kettle. After the equipment is ready, place it in a microwave hydrothermal instrument with a power of 400W, and conduct a microwave hydrothermal reaction at 200°C for 1 hour. After the reaction is completed and the instrument is automatically cooled, vacuum pump Filter, wash with deionized water and absolute ethanol three times each, place in a vacuum oven at 300°C, and dry for 0.5h to obtain Cu 2 V 2 o 7 -CuO nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com