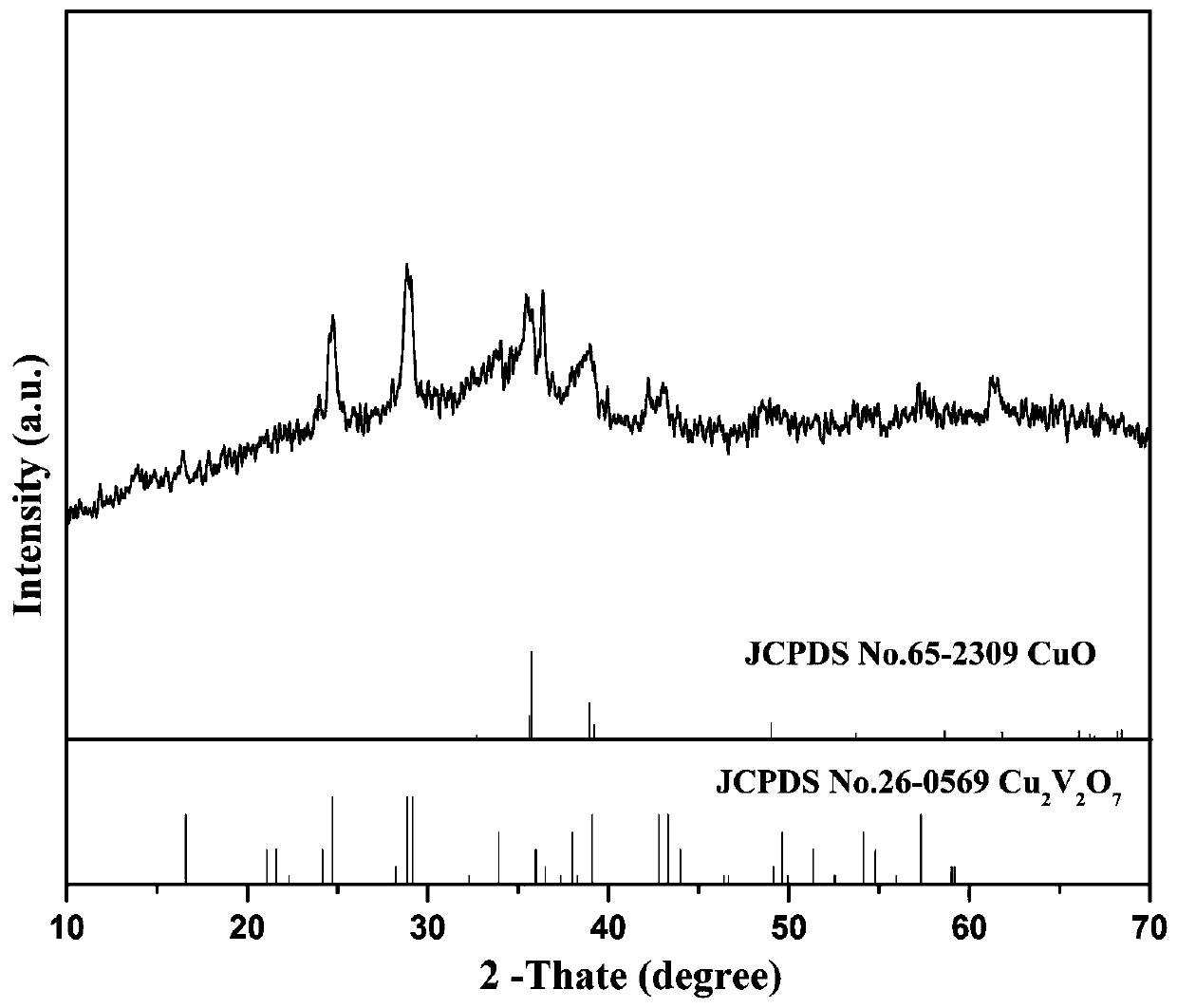

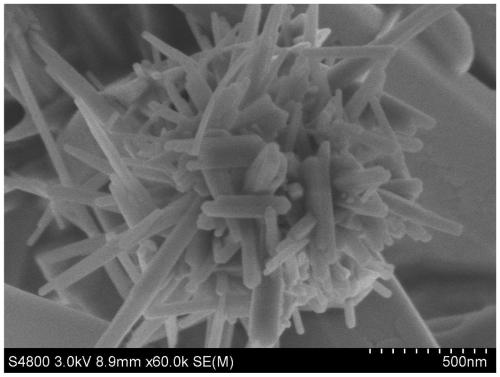

A solvothermal method for preparation of flower-like Cu 2 v 2 o 7 -cuo nanocomposite approach

A nanocomposite and solvothermal method, which is applied in the field of preparation of flower-like Cu2V2O7-CuO nanocomposites by solvothermal method, can solve the problems of affecting battery cycle stability, generating large stress, and large product size, etc. Short, good crystallinity, high reproducibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) will analytically pure V 2 o 5 The powder is dissolved in an aqueous hydrogen peroxide solution with a mass fraction of 15% to obtain V 5+ The concentration is 0.5mol / l brownish red transparent solution A;

[0021] 2) Under magnetic stirring, press V 5+ and Cu 2+ The molar ratio is 1:0.5 Add solution A to the concentration of 0.1mol / L Cu(CH 3 COO) 2 in ethanol solution;

[0022] 3) Use analytically pure sodium hydroxide to adjust the pH value of the solution to 7, and continue to stir to form a reaction precursor;

[0023] 4) Pour the reaction precursor into the reaction kettle, put it in a homogeneous hydrothermal instrument after the equipment is ready, and carry out the hydrothermal reaction at 100°C for 48 hours. Centrifuge and wash with water and ethanol three times respectively, and dry in an electric blast drying oven at 250°C for 2 hours to obtain flower-shaped Cu 2 V 2 o 7 -CuO nanocomposites.

Embodiment 2

[0025] 1) will analytically pure V 2 o 5 The powder is dissolved in an aqueous hydrogen peroxide solution with a mass fraction of 15% to obtain V 5+ The concentration is 0.3mol / l brownish red transparent solution A;

[0026] 2) Under magnetic stirring, press V 5+ and Cu 2+ The molar ratio is 1:1. Solution A is added to the concentration of 0.5mol / L Cu(CH 3 COO) 2 in ethanol solution;

[0027] 3) Use analytically pure sodium hydroxide to adjust the pH value of the solution to 8, and continue to stir to form a reaction precursor;

[0028] 4) Pour the reaction precursor into the reaction kettle, put it in the homogeneous hydrothermal instrument after the equipment is ready, and carry out the hydrothermal reaction at 150°C for 24 hours. Water and ethanol were washed by centrifugation for 3 times respectively, and dried in an electric blast drying oven at 300°C for 3 hours to obtain flower-shaped Cu 2 V 2 o 7 -CuO nanocomposites.

Embodiment 3

[0030] 1) will analytically pure V 2 o 5 The powder is dissolved in an aqueous hydrogen peroxide solution with a mass fraction of 15% to obtain V 5+ The concentration is 0.8mol / l brownish red transparent solution A;

[0031] 2) Under magnetic stirring, press V 5+ and Cu 2+ The molar ratio is 1:2. Solution A is added to the concentration of 1mol / L Cu(CH 3 COO) 2 in ethanol solution;

[0032] 3) Use analytically pure sodium hydroxide to adjust the pH value of the solution to 9, and continue to stir to form a reaction precursor;

[0033] 4) Pour the reaction precursor into the reaction kettle, put it in the homogeneous hydrothermal instrument after the equipment is ready, and carry out the hydrothermal reaction at 200°C for 8 hours. Centrifuge and wash with water and ethanol three times respectively, and dry in an electric blast drying oven at 300°C for 4 hours to obtain flower-shaped Cu 2 V 2 o 7 -CuO nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com