Single crystal submicron cu 2 znsns 4 High temperature solvothermal preparation method and application of particles

A submicron-scale, high-temperature solvent technology, applied in the direction of solution from liquid solvent at room temperature, single crystal growth, single crystal growth, etc., can solve the poor crystallinity of copper-zinc-tin-sulfur nanoparticles and the characteristics of copper-zinc-tin-sulfur nanocrystals Small peak intensity, long reaction time and other problems, to achieve the effect of easy large-scale application and promotion, good crystallinity, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

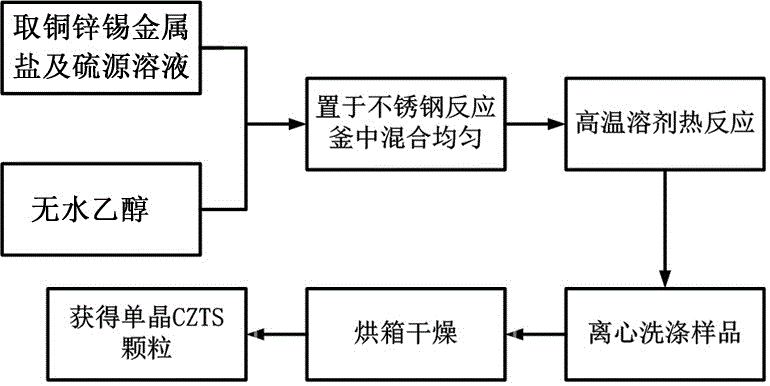

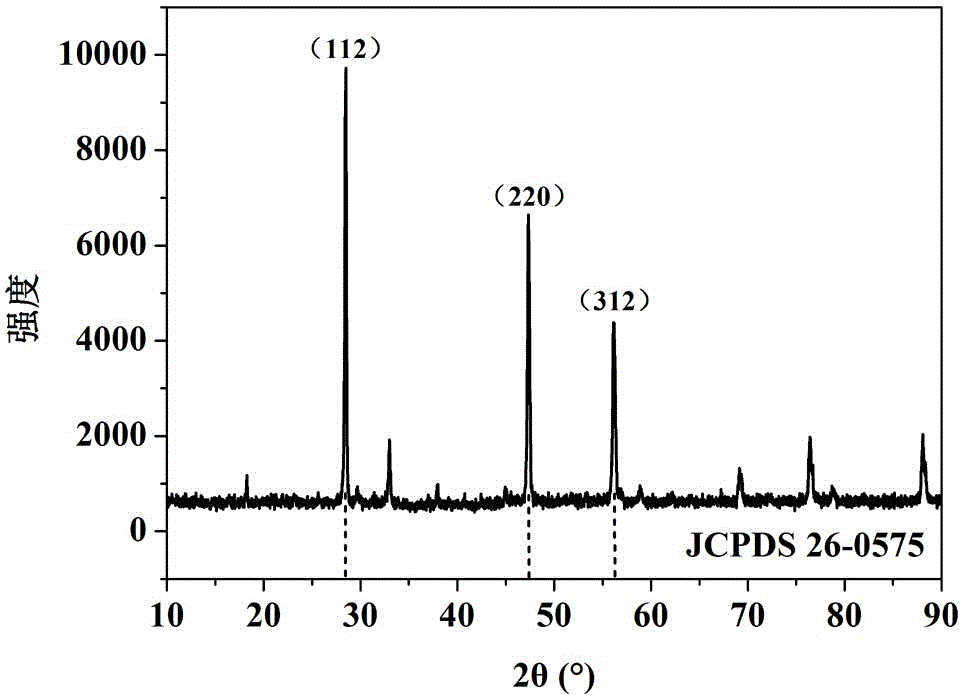

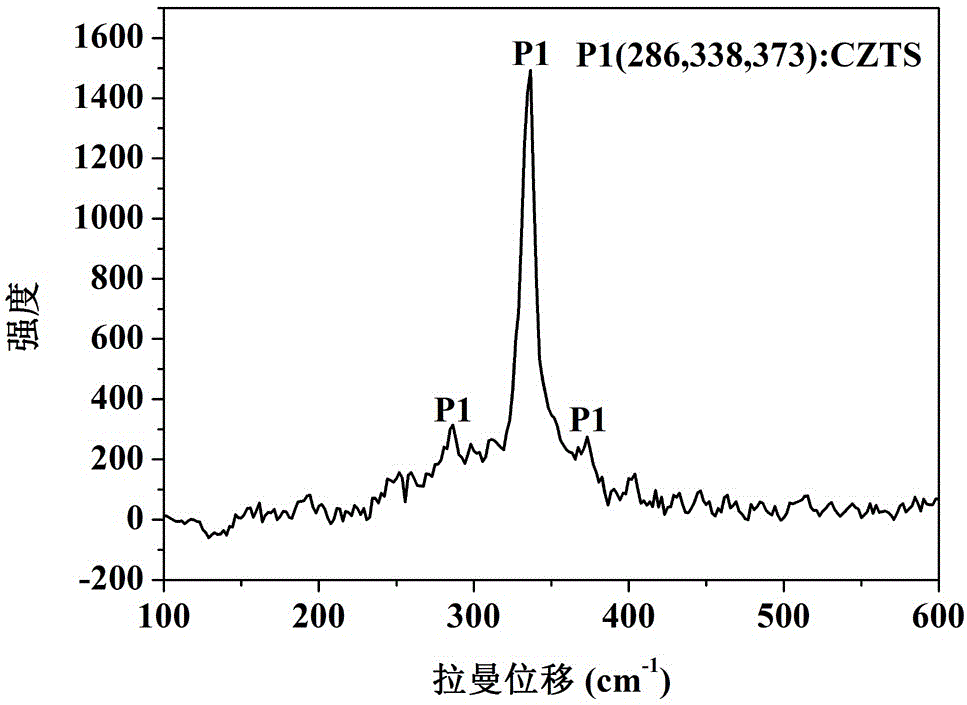

[0025] like figure 1 As shown, a single crystal submicron Cu of the present invention 2 ZnSnS 4 The specific steps of the high-temperature solvothermal preparation method of (CZTS) particles are as follows:

[0026] The first step, get the copper acetate monohydrate solution of 1mmol / L, the zinc acetate solution of 0.5mmol / L, the tin tetrachloride pentahydrate solution of 0.5mmol / L and the L-cysteine of 3mmol / L respectively, press The volume ratio is 1:1:1:1 to form a mixed solution and place it in a stainless steel reaction kettle, then pour it into analytical pure anhydrous ethanol for dilution to obtain a reaction precursor solution; the volume ratio of the mixed solution to analytical pure anhydrous ethanol is 1:1, the stainless steel reactor is polished with graphite powder before use.

[0027] In the second step, seal the stainless steel reaction kettle and place it in a high-temperature blast oven. Adjust the temperature rise rate of the oven to 10°C / min, keep it a...

Embodiment 2

[0033] The first step, get the copper acetate monohydrate solution of 0.5mmol / L, the zinc acetate solution of 0.5mmol / L, the tin tetrachloride pentahydrate solution of 0.5mmol / L and the L-cysteine of 4mmol / L respectively, According to the volume ratio of 1:1:1:1, the mixed solution is formed and placed in a stainless steel reaction kettle, and then poured into analytical pure anhydrous ethanol for dilution to obtain a reaction precursor solution; the volume ratio of the mixed solution to analytical pure anhydrous ethanol The ratio is 1:1, and the thread of the stainless steel reactor is polished with graphite powder before use; the rest of the steps are the same as in Example 1.

Embodiment 3

[0035]The first step, get respectively the copper acetate monohydrate solution of 0.7mmol / L, the zinc acetate solution of 0.5mmol / L, the tin tetrachloride pentahydrate solution of 0.5mmol / L and the L-cysteine of 4mmol / L, According to the volume ratio of 1:1:1:1, the mixed solution is formed and placed in a stainless steel reaction kettle, and then poured into analytical pure anhydrous ethanol for dilution to obtain a reaction precursor solution; wherein, the volume of the mixed solution and analytical pure anhydrous ethanol The ratio is 1:1, and the thread of the stainless steel reactor is polished with graphite powder before use; the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com