Rapid synthesis method of Sn-doped MFI zeolite molecular sieve

A technology for zeolite molecular sieves and synthesis methods, applied in molecular sieves and base exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problem of large amount of structure-directing agent, hindering crystallization of molecular sieves, long crystallization time, etc. problems, to achieve the effect of easy industrial application, high crystallinity, and short crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

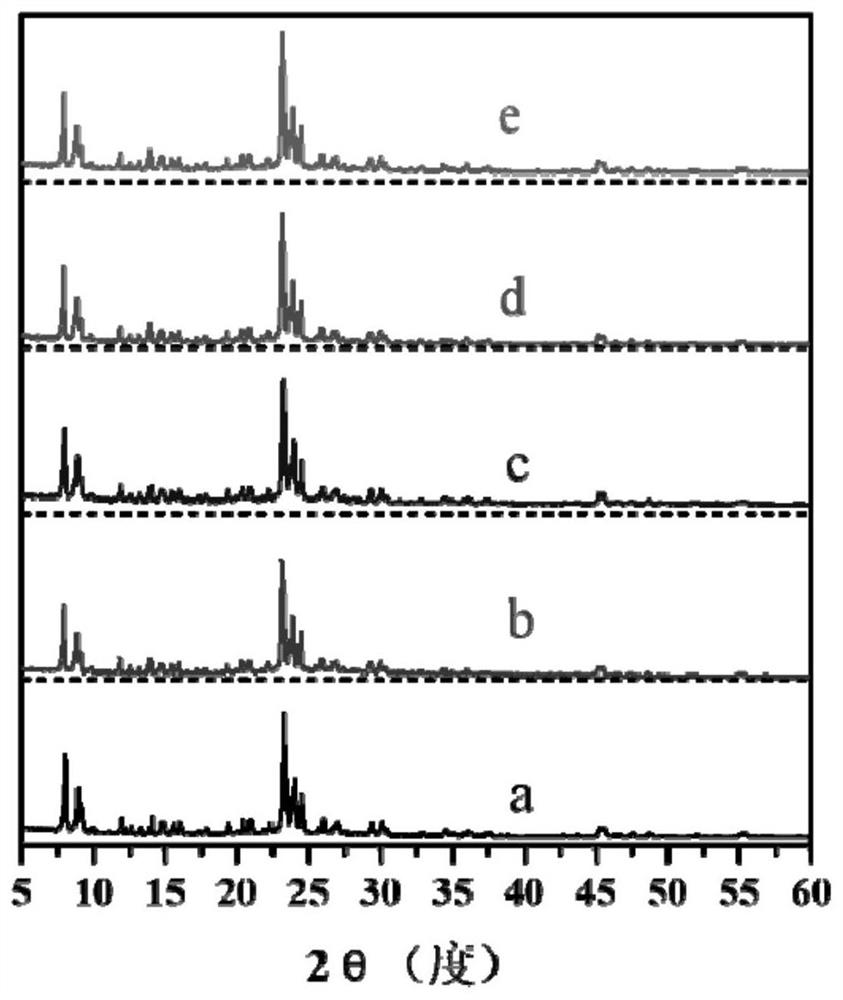

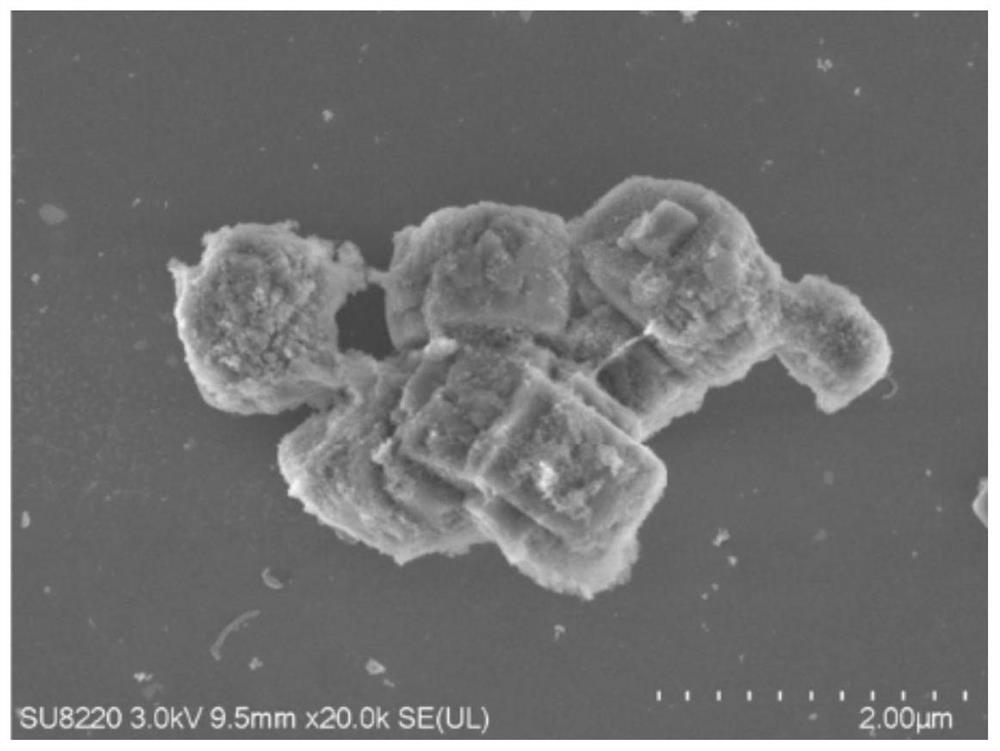

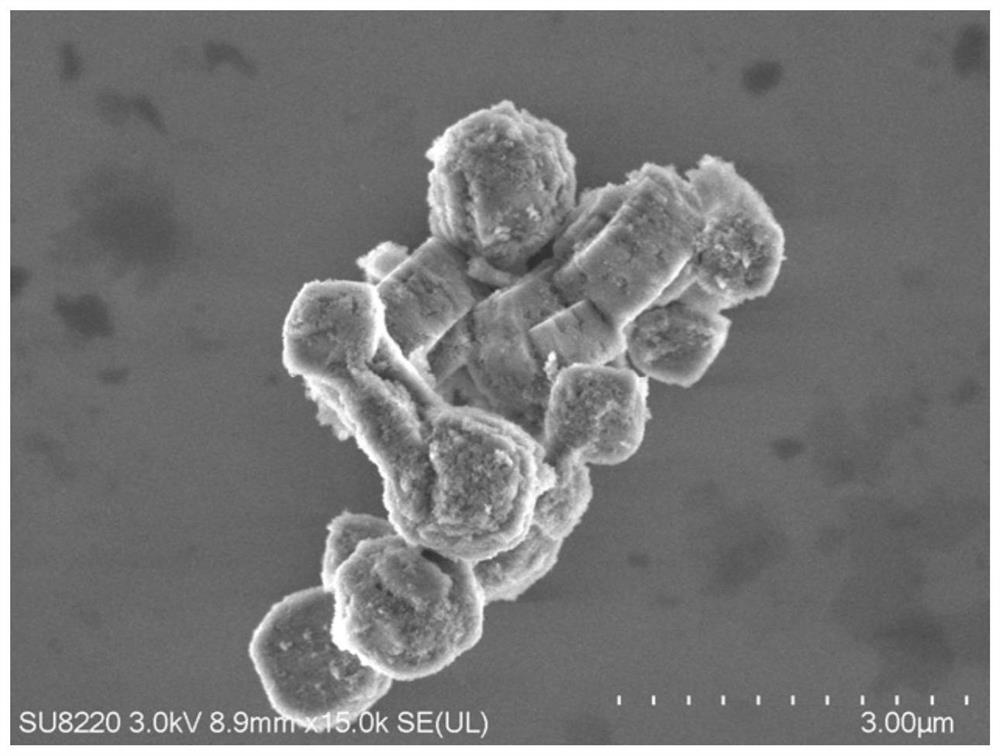

Embodiment 1

[0020] According to the molar ratio: Sn / SiO 2 =0.02, structure directing agent / SiO 2 =0.18, Alkali / SiO 2 =0.02,H 2 O / SiO 2 =6.6, the mass ratio is: silicate-1 molecular sieve / SiO 2 =0.04, polymer / SiO 2 =0.11, at first 13.6g fumed silica, 0.2g NaOH, 33.6g tetrapropyl ammonium hydroxide (mass fraction is 25% aqueous solution), 2mL deionized water, 1.8gSnCl 4 ·5H 2 O mixed, ground for 30 minutes, added 0.6g silicate-1 molecular sieve, continued to grind for 30 minutes, then added 1.5g of polydiallyldimethylammonium chloride (PDDA), continued to grind for 30 minutes, and the resulting gel was transferred to a polytetrafluoroethylene In a stainless steel high-pressure hydrothermal reaction kettle lined with ethylene, crystallize in a constant temperature drying oven at 200°C for 3h, cool to room temperature, centrifuge and wash with water until neutral, dry in a constant temperature drying oven at 80°C for 24h, and then transfer to a horse Sn-doped MFI zeolite molecular siev...

Embodiment 2

[0022] According to the molar ratio: Sn / SiO 2 =0.05, structure directing agent / SiO 2 =0.24, Alkali / SiO 2 =0.02,H 2 O / SiO 2 =6.4, the mass ratio is: silicate-1 molecular sieve / SiO 2 =0.12, polymer / SiO 2 =0.32, firstly mix 10.0g sodium silicate, 0.05g NaOH, 10.0g tetrapropylammonium hydroxide (25% aqueous solution), 2mL deionized water, 1.5g SnCl 4 ·5H 2 O mixed, grinded for 30 minutes, added 0.6g silicate-1 molecular sieve, continued to grind for 30 minutes, then added 1.6g polyethylene terephthalate (PET), continued to grind for 30 minutes, and the resulting gel was transferred into a polytetrafluoroethylene In a lined stainless steel high-pressure hydrothermal reaction kettle, crystallize in a constant temperature drying oven at 190°C for 10h, cool to room temperature, centrifuge and wash to neutrality, dry in a constant temperature drying oven at 80°C for 24h, and then transfer to a muffle furnace Calcined at 550°C for 6h to obtain Sn-doped MFI zeolite molecular sieve...

Embodiment 3

[0024] According to the molar ratio: Sn / SiO 2 =0.04, structure directing agent / SiO 2 =0.2, Alkali / SiO 2 =0.11,H 2 O / SiO 2 =8, the mass ratio is: silicate-1 molecular sieve / SiO 2 =0.05, polymer / SiO 2 =0.17, first 30.0g tetraethyl orthosilicate, 0.50g NaOH, 19.0g tetrapropylammonium hydroxide (25% aqueous solution), 2mL deionized water, 1.6g SnCl 4 ·5H 2 O mixing, grinding for 30min, adding 0.5g silicate-1 molecular sieve, continuing grinding for 30min, then adding 1.6g polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123), continuing grinding for 30min , the resulting gel was transferred to a stainless steel high-pressure hydrothermal reaction kettle with a polytetrafluoroethylene liner, crystallized in a constant temperature drying oven at 170 ° C for 10 h, cooled to room temperature, centrifuged and washed to neutrality, and placed in a constant temperature drying oven Dry at 80°C for 24h, and then transfer to muffle furnace for calcinatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com