Thermotropic hydrogel sustained-release veterinary drug injection for animal contraception and preparation method thereof

A hydrogel and injection technology, applied in the field of pharmaceutical preparations, can solve problems such as poor compliance, low drug loading, and limited application, and achieve the effects of cost saving, simple synthesis, and prolonged release period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Add 20 g of PEG (1000) into a 250 mL three-necked bottle, set the temperature of the oil bath to 125 °C, vacuum filter at a stirring speed of 70 r / min for 3 h, and change argon 3-4 times during this period. After the flask was cooled down slowly, 43 g and 7 g of D, L-lactide and glycolide respectively in a molar ratio of 5:1 were added. After it was completely dissolved, about 0.25 wt% stannous octoate was added, the temperature of the oil bath was raised to 160 °C, and the reaction was continued for 12 h under an argon atmosphere. After the reaction was completed, the unreacted monomer and low boiling point products in the system were removed by vacuum filtration for 2 h. Finally, the product was transferred to hot water at 80 °C, and the supernatant was poured out after standing for precipitation, repeated washing three times, and vacuum-dried for 48 hours to obtain the BAB type triblock copolymer PLGA-PEG-PLGA with a yield of about 80%. The number-average and weight...

Embodiment 2

[0044] Add 20 g of PEG (1500) into a 250 mL three-necked bottle, set the temperature of the oil bath to 125 °C, vacuum filter at a stirring speed of 70 r / min for 3 h, and change the argon gas 3-4 times during this period. After the flask was cooled down slowly, 42 g and 3.4 g of D, L-lactide and glycolide respectively in a molar ratio of 10:1 were added. After it was completely dissolved, about 0.25 wt% stannous octoate was added, the temperature of the oil bath was raised to 160 °C, and the reaction was continued for 12 h under an argon atmosphere. After the reaction was completed, the unreacted monomer and low boiling point products in the system were removed by vacuum filtration for 2 h. Finally, the product was transferred to hot water at 80 °C, and the supernatant was poured after standing for precipitation, and the washing was repeated 3 times. After vacuum drying for 48 hours, the BAB type triblock copolymer PLGA-PEG-PLGA was obtained with a yield of about 85%. The nu...

Embodiment 3

[0046] Add 20 g of PEG (1500) into a 250 mL three-necked bottle, set the temperature of the oil bath to 125 °C, vacuum filter at a stirring speed of 70 r / min for 3 h, and change the argon gas 3-4 times during this period. After the flask was cooled slowly, 42.6 g and 5.4 g of caprolactone (CL) and glycolide (GA), respectively, were added in a molar ratio of 4:1. After it was completely dissolved, about 0.25 wt% stannous octoate was added, the temperature of the oil bath was raised to 160 °C, and the reaction was continued for 12 h under an argon atmosphere. After the reaction was completed, the unreacted monomer and low boiling point products in the system were removed by vacuum filtration for 2 h. Finally, the product was transferred to hot water at 80 °C, and the supernatant was poured out after standing for precipitation, repeated washing three times, and vacuum-dried for 48 hours to obtain the BAB type triblock copolymer PCGA-PEG-PCGA with a yield of about 76%. The number...

PUM

| Property | Measurement | Unit |

|---|---|---|

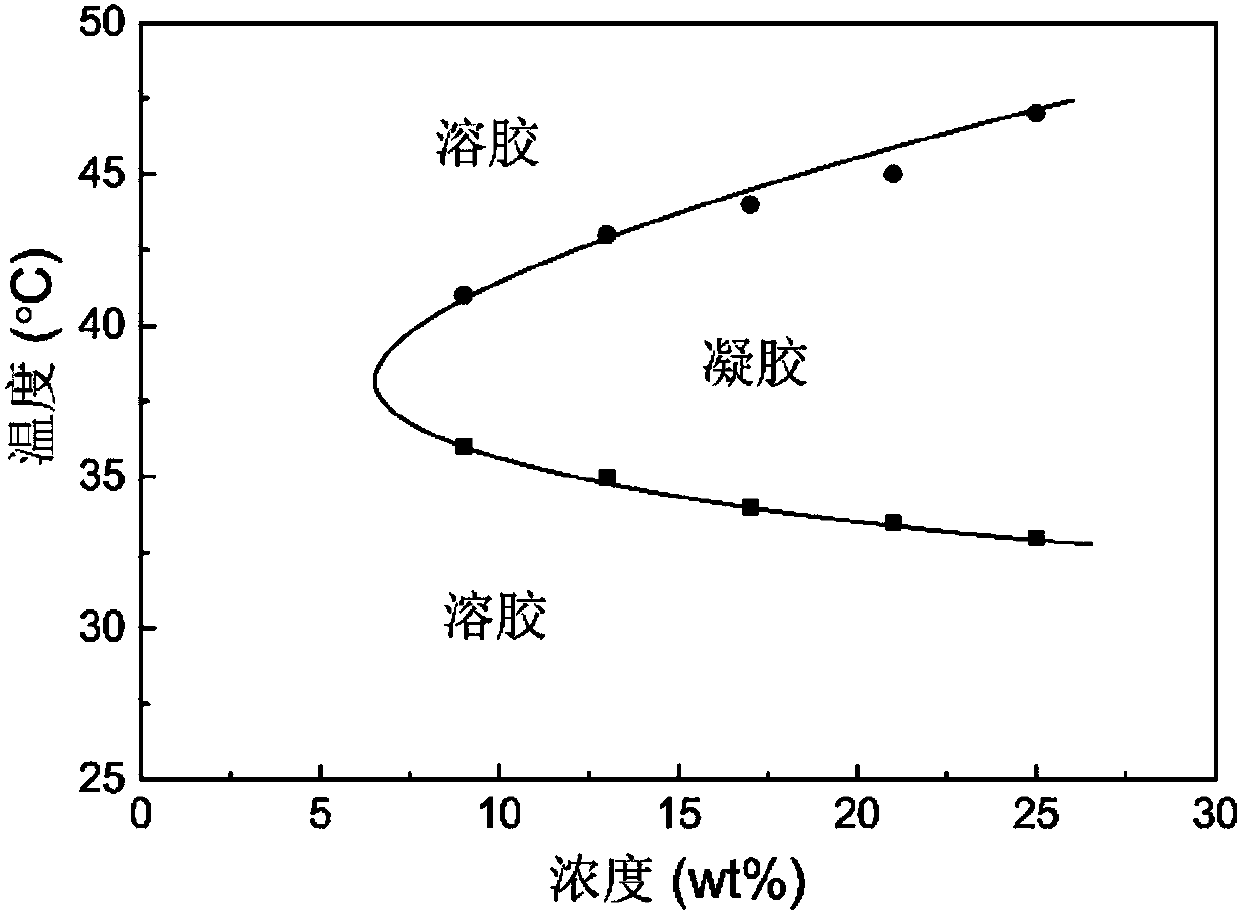

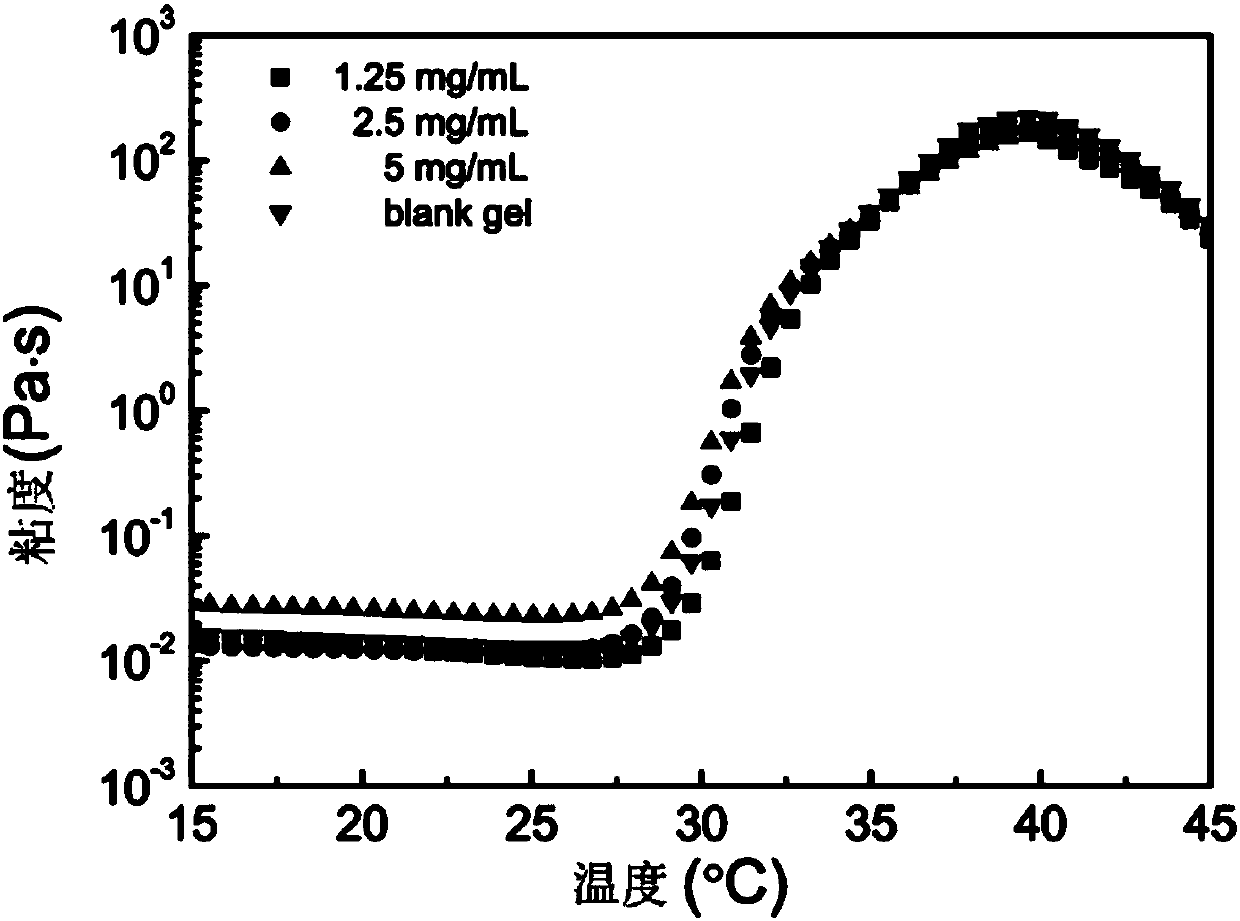

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com