Rare earth material industrial exhaust gas purifying agent based on perovskite-type composite oxide

A composite oxide and perovskite-type technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of poor catalyst effect, inconvenient use, Solve the problems of low photocatalytic performance, achieve the effect of simple structure, reasonable design, and improved sensitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

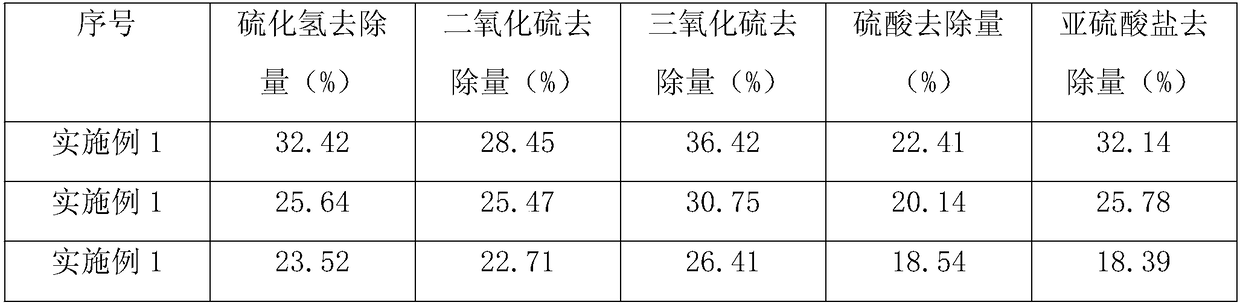

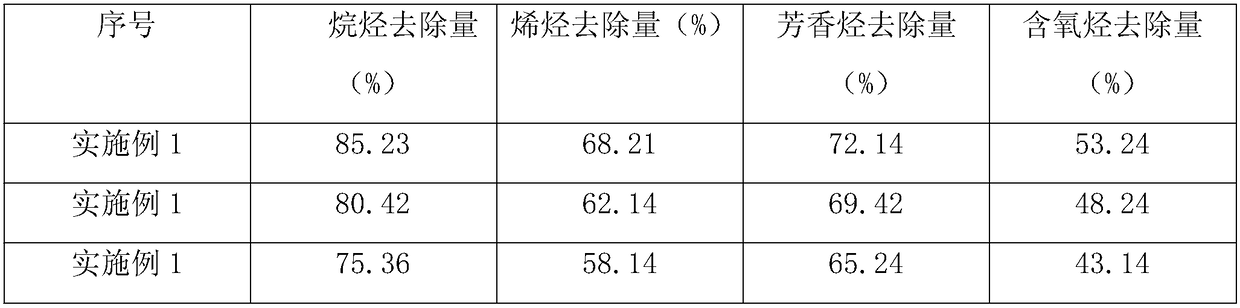

Embodiment 1

[0023] The invention provides a perovskite-type composite oxide-based rare-earth material industrial waste gas purifier, which comprises the following components in weight percent: 20% of grape polyphenols, 8% of acid resistance, 10% of titanium dioxide, and 0.5% of penetrant %, PH adjustment value 1.0%, perovskite composite oxide 20%, activated carbon 2.0%, humectant 0.5%, and the rest is purified water.

[0024] As a preferred technical solution of the present invention, the preparation method is as follows:

[0025] Step 1: Put grape polyphenols and acid-resistant acid in a glass container, add hydrogen peroxide, stir with a stirring bar for 3 minutes, and let stand for 1 minute;

[0026] Step 2: adding a pH regulator to the above solution to adjust the pH value of the solution to 6;

[0027] Step 3: adding titanium dioxide to the solution described in Step 2, and adding a small amount of pure water, stirring for 3 minutes with a stirring bar, and standing for 2 minutes; ...

Embodiment 2

[0033] The invention provides a perovskite-type composite oxide-based rare earth material industrial waste gas purifier, comprising the following components in weight percent: 15% of grape polyphenols, 5% of acid-resistant acid, 8% of titanium dioxide, and 0.2% of penetrant %, pH adjustment value 0.8%, perovskite composite oxide 15%, activated carbon 1.5%, humectant 0.4%, and the rest is purified water.

[0034] The preparation method is as follows:

[0035] Step 1: Put grape polyphenols and acid-resistant acid in a glass container, add hydrogen peroxide, stir with a stirring bar for 3 minutes, and let stand for 1 minute;

[0036] Step 2: adding a pH regulator to the above solution to adjust the pH value of the solution to 6;

[0037] Step 3: adding titanium dioxide to the solution described in Step 2, and adding a small amount of pure water, stirring for 3 minutes with a stirring bar, and standing for 2 minutes;

[0038] Step 4: Add the perovskite-type composite oxide into ...

Embodiment 3

[0043] The invention provides a perovskite-type composite oxide-based rare-earth material industrial waste gas purifier, which comprises the following components in weight percent: 12% of grape polyphenols, 7% of acid-resistant acid, 8% of titanium dioxide, and 0.2% of penetrant %, pH adjustment value 0.5%, perovskite composite oxide 10%, activated carbon 1.2%, humectant 0.4%, and the rest is purified water.

[0044] The preparation method is as follows:

[0045] Step 1: Put grape polyphenols and acid-resistant acid in a glass container, add hydrogen peroxide, stir with a stirring bar for 3 minutes, and let stand for 1 minute;

[0046] Step 2: adding a pH regulator to the above solution to adjust the pH value of the solution to 6;

[0047] Step 3: Add titanium dioxide to the solution described in Step 2, and add a small amount of pure water, stir for 3 minutes with a stirring bar, and let stand for 2 minutes;

[0048] Step 4: Add the perovskite-type composite oxide into the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com