Method for repairing and regenerating graphite negative electrode waste

A graphite anode, repair and regeneration technology, applied in chemical instruments and methods, battery electrodes, electrochemical generators, etc., can solve the problems of graphite anode waste that cannot be directly reused, has not been recycled, and has no repair methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take 1.0Kg and put the natural graphite negative electrode waste recovered from scrap batteries into a muffle furnace, calcinate at 300°C for 0.5h in an air atmosphere, remove the conductive agent, binder, and thickener, and obtain a calcined product of 0.97 Kg;

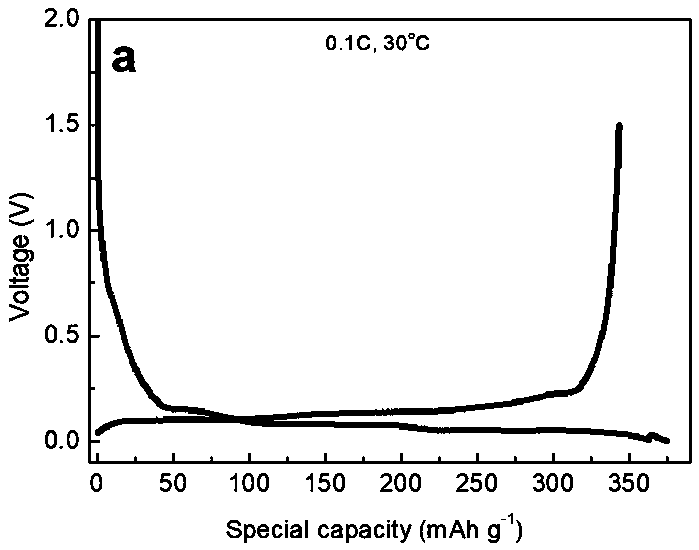

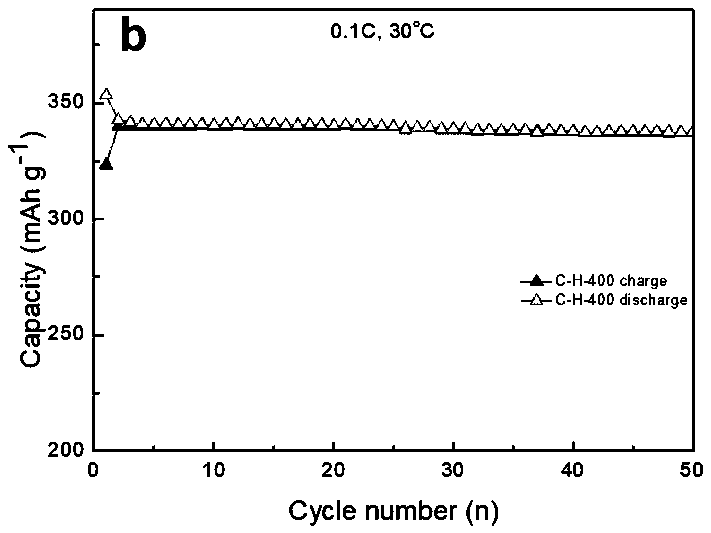

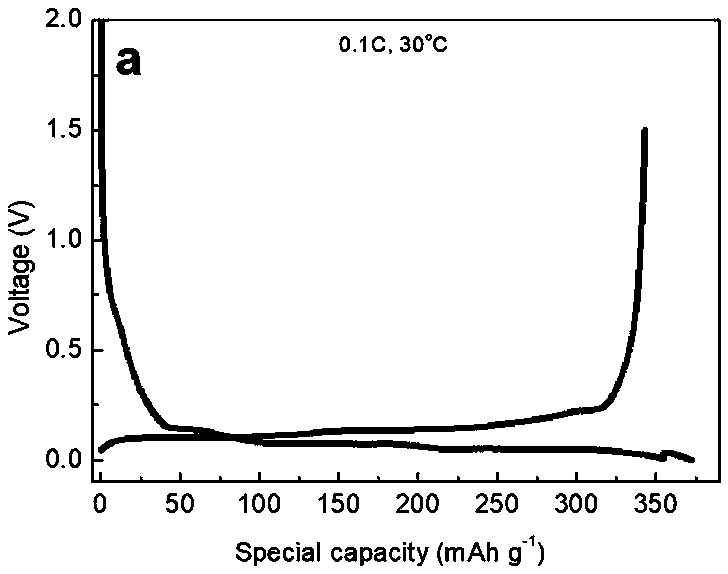

[0038] Take 500g of the calcined product and put it into a 5L beaker, add 2L of water, add 80mL of hydrogen peroxide and 640mL of hydrochloric acid mixed solution at a stirring speed of 200 rpm, the pH value of the mixed solution is 1, soak for 1 hour, then filter and wash To neutral, dry at 100°C to obtain purified graphite. The graphite after the sieving is poured into the ethanol that is dissolved with phenolic resin, so that the coating amount of phenolic resin is 3wt.%, stir 5h under the rotating speed of 250 rev / mins, make phenolic resin particle adsorb on graphite particle surface, Suction filtration and drying to obtain graphite particles with phenolic resin adsorbed on the surface; put the above-ment...

Embodiment 2

[0041] Take 1.0Kg and put the natural graphite negative electrode waste recovered from scrap batteries into a muffle furnace, calcinate at 500°C for 1h in an air atmosphere, remove the conductive agent, binder and thickener, and obtain 0.96Kg of calcined product ;

[0042] Take 500g of the calcined product and put it into a 5L beaker, add 2L of water, add 80mL of hydrogen peroxide and 300mL of sulfuric acid mixed solution at a stirring speed of 200 rpm, the pH value of the mixed solution is 1.4, soak for 3 hours, then filter and wash To neutral, dry at 100°C to obtain purified graphite. The graphite after sieving is poured into the ethanol that is dissolved with phenolic resin, so that the coating amount of phenolic resin is 5wt.%, stir 5h under the rotating speed of 250 rev / mins, make phenolic resin particle adsorb on graphite particle surface, Suction filtration and drying to obtain graphite particles with phenolic resin adsorbed on the surface; put the above-mentioned grap...

Embodiment 3

[0045] Take 1.0Kg and put the natural graphite negative electrode waste recovered from scrap batteries into a muffle furnace, and calcinate in an air atmosphere at 600°C for 1.5h, remove the conductive agent, binder, and thickener, and obtain a calcined product of 0.97 Kg;

[0046] Take 500g of the calcined product and put it into a 5L beaker, add 2L of water, add 80mL of hydrogen peroxide and 240mL of sulfuric acid mixed solution at a stirring speed of 200 rpm, the pH value of the mixed solution is 2, soak for 3 hours, then filter and wash To neutral, dry at 100°C to obtain purified graphite. The graphite after the sieving is poured into the ethanol that is dissolved with phenolic resin, so that the coating amount of phenolic resin is 7wt.%, stir 5h under the rotating speed of 250 rev / mins, make phenolic resin particle adsorb on graphite particle surface, Suction filtration and drying to obtain graphite particles with phenolic resin adsorbed on the surface; put the above gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com